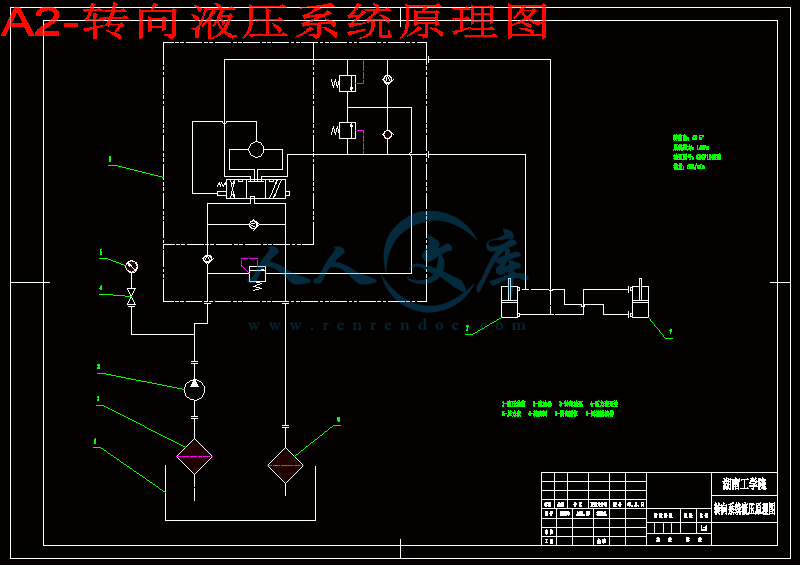

摘 要:详细介绍了CA-20地下自卸汽车工作液压系统和转向液压系统的设计,为四个步骤:根据各个系统的功能和整车布置拟定液压系统原理图;根据翻倾及转向角度分别计算工作油缸的行程;根据各系统所受的最大作用力确定系统压力;根据各系统的系统压力和流量选定各系统的泵及其他液压元件。实践CA-20地下自卸汽车液压系统是安全、可靠和高效的。

关键词:地下自卸汽车;工作液压系统;转向液压系统;泵;油缸;

Abstract: In this paper the design of the hydraulic systems of working and steering for CA-20 Rear Dump Truck is introduced. The design include four steps. First of all according to the feature of each hydraulic system, we can draw the principle diagrams of the hydraulic systems of working and steering. Then we can calculate the travels of the dumping cylinders and steering cylinders by the angles of dumping and steering. And then we can decide the pressure of each hydraulic system through the maximal force on each system. At last may chose the pumps and other hydraulic parts according to the pressure and the flow of each hydraulic system, The fact has proved that the hydraulic system of the truck is safe, reliable and efficient.

Key words: Rear dump truck Hydraulic system of working hydraulic system of steering Pump Cylinder

目录

一、绪论

(一)立项背景 1

(二)国内外研究现状与发展趋势 3

(三)项目实施的主要内容、技术关键与创新点、预期目标 5

(四)应用或产业化前景与市场需求 6

(五)现有工作基础、条件和优势 7

二、液压系统参数计算

(一)概述 8

(二)工作液压系统参数计算 8

(三)转向液压系统参数计算12

(四)变矩器与发动机优化匹配MATLAB程序的编制 18

(五)液压缸装配、维护、修理工艺 30

37

三、参考文献 50

谢辞51

附页52

一、绪 论

(一)立项背景:

地下自卸汽车是实现无轨开采技术的主要运输设备,它具有机动灵活和经济的优越性,广泛用语条件适宜的地下矿山。随着无轨采矿技术的发展,对地下自卸汽车的需求量也愈来愈大,对它的经济性、生产能力与可靠性的要求也愈来愈高,生产地下自卸汽车的厂家也愈来愈多。除了专门生产地下自卸汽车的厂家之外,生产露天自卸汽车的厂家也纷纷将露天自卸汽车改造后用于地下,企业之间的竞争愈来愈激烈。各企业为了适应市场的变化,提高市场的竞争力,不断推出新技术、新品种、新结构和新材料,促进了无轨采矿技术与设备的发展。

国内研制地下自卸汽车始于20世纪70年代中期,由于各种原因,至今发展不快,只有几个生产厂,技术水平只相当于国外20世纪80年代末的水平,数量与质量也远远满足不了国内矿山发展的需要。我们加入了WTO之后,地下自卸汽车行业面临着极大的压力和挑战,为了对付这严峻的形势一方面要引进更多更好的国外产品与相关技术,另一方面必须迅速发展民族工业。

进入21世纪以来,我国的矿业形势发生了很大的变化。许多露天矿山,由于开采深度不断增加,为了降低开采成本、保护环境,这些矿山必须由露天开采转入地下开采。据有关协会统计,我国的铁矿山在5年后,露天开采与地下开采的比将由目前的7∶3转变成3∶7,由此可见,地下矿山设备在我国的应用前景十分广阔。据有关资料分析,我国今后地下矿山自卸汽车的需求量将呈逐年上升的趋势。目前的年需求量约30台左右,5年后年需求量约120台左右。

由于历史的原因,我国在地下矿山运输设备领域装备十分落后,尽管经过太原重型机械厂、北京矿冶研究总院、核工业第六研究所、衡阳有色冶金机械厂、金川有色公司、长沙矿山研究院等单位的努力,分别对5t、8t、10t、12t、18t、20t、25t等机型进行了一些研究,取得了一些成功,但这些探索性的研究显然还很不够,而且有些探索显然没有达到预期的目的。因此,直到目前我国可供矿山选用的地下矿山自卸汽车比较少,远远不能满足我国地下矿山运输设备需要。

国外的地下矿山自卸汽车应用得比较好,技术也比较先进,但价格比较高。一般情况是:国外的地下矿山自卸汽车整机的价格是国内价格的2~3倍,而易损件、备件的价格却是6~10倍。因此,发展我国的地下矿山自卸汽车是非常必要的。

20t地下矿山自卸汽车是我国矿山应用较多的一种机型,它比较适合中型规模的地下矿山。我国的有些公司对它有过探索,但没有达到预期的目的,至今没有该产品通过鉴定的报道。因此,我国的20t地下矿山自卸汽车目前还停

川公网安备: 51019002004831号

川公网安备: 51019002004831号