摘 要

论文主要介绍了一种新型的自动售货机用取物箱的设计过程。在设计过程中还综合各方面因素对设计做了多次改进,简述了自动售货机的原理、分类以及内部结构与电子元件和国内外发展概况。就实际使用中所出现的因防盗板运动方式的不同所引起的取物箱高度过高而导致的取物箱体积增大的问题,提出了解决方法。运用PLC对自动售货机的控制系统做了设计。新型的防盗板联动机构具有结构简单、运动平稳、受力情况好、成本低、加工容易等优点。新型取物箱的结构设计运用了机械设计、机械原理、材料力学、创新思维等多方面的知识,是对所学知识的一次综合考验。此次设计的取物箱大多数零件都是钣金件,因此,为了完成这一设计,我学会了运用Solid Edge三维绘图软件,此软件最大的优点就是具有强大的钣金件建模能力。此外,我还充分利用了AutoCAD软件强大的参数化特征将设计图形显而易懂的呈现在大家面前。

关键词:自动售货机;取物箱;防盗板;钣金;Solid Edge;AutoCAD;PLC

Abstract

This paper mainly introduced a new type of vending machine in the design process of take content box. Also synthesized various aspects factor in the design process to design does improved many times, has summarized the limiting condition and the domestic development survey which the vending machines,classification , the internal structure and electronic components ,the domestic and foreign development situation. According to the practical use of guard against theft occurred because of the different ways of plate movement caused by the content box highly exorbitant and take the lead to take content box the increase in size, solutions are put forward. I did the application of PLC control system of the vending machine to do the design The new security board linkage mechanism possesses simple structure, smooth movement, force of good, Low cost, easy processing. Take the new content box structure design using a mechanical design, mechanical principle, material mechanics, innovative thinking and so on various knowledge, is the knowledge of a comprehensive test.The design of the take content box is most parts metal sheet, Therefore, in order to finish the design, I learned to use Solid Edge 3D drawing software. Besides that I fully design the graph using the AutoCAD software formidable parametrization characteristic to reveal easy to understand present in front of us.

Key words:Vending machine ;Take content box ;Security board;Sheet metal parts ;Solid Edge ;AutoCAD;PLC

目 录

摘 要III

AbstractIV

1 绪论1

1.1 课题来源1

1.2 本课题的研究内容和意义1

1.2.2 设计意义1

1.3 自动售货机的起源、兴起和普及1

1.3.1 起源1

1.3.2 兴起2

1.3.3 自动售货机产业的普及2

1.4 自动售货机在国内的发展2

1.5 自动售货机在国外的应用3

1.6 自动售货机在国外的市场发展4

1.7 新型自动售货机的新增功能4

2 自动售货机的分类6

3 自动售货机的结构与功能分析7

3.1 结构7

3.2 功能分析8

4 自动售货机的控制技术10

4.1 PLC的系统结构11

4.2 I/O分配表11

4.3 PLC外部接线图12

4.4 梯形图程序13

5 取物箱的结构与作用16

5.1 结构16

6 取物箱不同防盗结构的比较18

6.1 传统取物箱防盗结构18

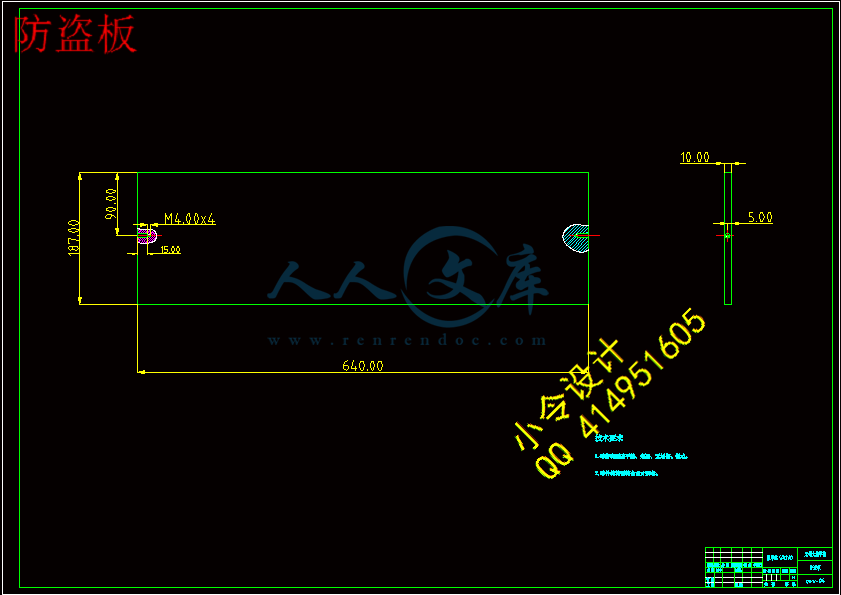

6.2 改进后取物箱防盗机构18

7 取物箱箱体结构的设计20

8 取物箱材料的选择21

8.1 箱体材料的选择21

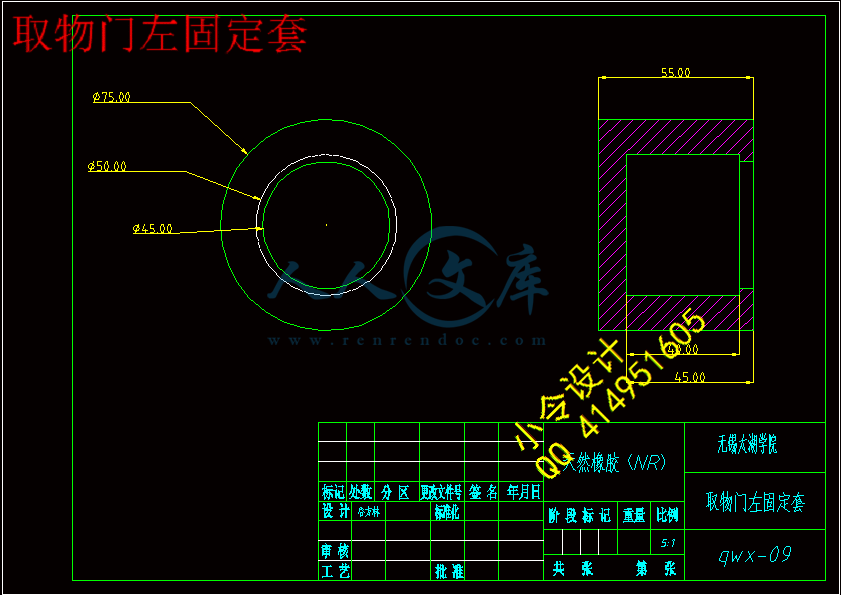

8.2 取物门与防盗板材料的选择21

8.3 取物门固定套材料的选择21

9 取物箱中力的计算22

10 联动轴扭矩计算24

11 取物门旋转角度的选择25

12 取物箱的三维效果27

13 结论与展望31

13.1 结论31

13.2 存在的不足及对未来的展望31

致 谢32

参考文献33

1 绪论

1.1 课题来源

自动售货机是可完成无人自动售货,集光、机、电一体化的商业自动化设备。自动售货机不受任何场地限制,方便快捷,很多城市的公共场所里面都放置有自动售货机。从自动售货机的发展趋势来看,它的出现是由于劳动密集型的产业构造向技术密集型社会转变的产物。大量生产、大量消费以及消费模式和销售环境的变化,要求出现新的流通渠道;而相对的超市、百货购物中心等新的流通渠道的产生,人工费用也不断上升;再加上场地的局限性以及购物的便利性等这些因素的制约,无人自动售货机作为一种必须的机器便应运而生了。 可编程序控制器(PLC)是综合了计算机技术、自动控制技术和通讯技术而发展起来的一种新型的工业控制装置,它具有可靠性高、编程简单、维护方便等优点,已在工业控制领域得到广泛地应用。本课题实现自动售货机的取物箱的防盗装置和联动机构的设计更为紧凑,比较大程度的减少取物箱的体积。 自动售货机行业长期以来在美国、日本等国家得到迅猛发展,目前已在45个国家得到广泛普及。据业内人士估计,中国的自动售货机拥有量仅有2万台,相对于13亿的人口大国和零售业态发展的趋势而言,中国自动售货机行业的发展空间将更加广阔。 可编程序控制器( PLC)是综合了计算机技术、自动控制技术和通讯技术而发展起来的一种新型的工业控制装置,它具有可靠性高、程序简单、维护方便等优点,已在工业控制领域得到广泛地应用,因为自动售货机作为社会上完成商品零售和综合服务的独立设施,要求它的结构必须可靠、稳定和执行效率高。一种新型的自动售货机用取物箱的设计保证自动售货机能够长期安全稳定运行。本文就详细地介绍PLC实现的自动售货机控制系统的硬件设计和软件设计,新型的取物箱的设计过程。

1.2 本课题的研究内容和意义

1.2.1 研究内容

设计一种新型的自动售货机用取物箱,主要是将传统的向上翻转的防盗板改变为平移式防盗板,该取物箱可以有效的降低设计高度,有效节约设计空间,适用于售货机比较紧凑的内部空间,从而可有效降低取物箱的高度。

1.2.2 设计意义

降低取物箱的高度可以减少它所占的体积,从而可以为物品展示区和储物箱腾出更多的空间,这样一来,自动售货机可以为消费者提供更多的商品,提高单台售货机的销售量,为企业创造更多的经济利润!

1.3 自动售货机的起源、兴起和普及

1.3.1 起源

自动售货机的历史,可一直追溯到远古时代的埃及。亚历山大的科学家HERON在其所著的《气体装置(PNEUMATIKA)》中描述,只要将钱币投入该装置,水就会自动流出来。这就是自动售货机的起源,大约在公元前215年左右,埃及寺院中就安装了这种装置,用来销售“神圣之水(圣水)”。

1.3.2 兴起

日常生活中最重要的是方便,自动售货机最早出现在二十世纪五六十年代的西欧,当时在美国的地铁中,人们可以用1美分在自动售货机上买到一块口香糖。

第二次世界大战后,经济开始复兴的1957年,以日本作为代表,开发出了饮料自动售货机。只要在饮料自动售货机中投入10日元,就会在纸杯内注入一定量的果汁。由于机器的上部安装有引人注目的喷水装置,所以该自动售货机被称为“喷水型果汁自动售货机”,自此出现了爆发性的自动售货机狂潮。此种喷水型果汁自动售货机为消费者带来了新奇、前卫的购买方式,并对之后日本的自动售货机高度普及起到了很大的作用。之后登场的是可乐自动售货机。随着美国大型可乐公司正式进驻日本市场,到了1960年代中期,罐装饮料自动售货机也登场了。自动售货机的活跃表现对可乐销量的惊人增长贡献巨大。同时,优秀的自动售货机市场战略、操作技巧等都对日本的自动售货机产业的发展产生了很大的影响。1962年,作为流通领域革命的使者,拉开了自动售货机的序幕。一开始是瓶装饮料自动售货机。1967年,100日元单位以下的货币全部改为硬币,从而促进了自动售货机产业的发展。

自动售货机在日本被亲切地称为“微型小店”。“微型小店”出售的商品,从咖啡、香烟、各种酒类已经发展到部分日常生活用品,就连报纸、大米、邮票、明信片、电池、录像带等也可以自动出售。现在,自动售货机除路旁以外,已进入学校、工厂、医院、游戏厅、麻将馆、影剧院等公共场所。作为世界上最大的自动售货市场,日本已有560万台,通过自动售货机出售的商品多达6000余种,年营业额7兆1122亿日。每年,仅饮料的销售额相当于1593亿元人民币,按人口计算,每23人就拥有1台自动售货机,平均每人在自动售货机上的消费达56000日元。

1.3.3 自动售货机产业的普及

随着经济的发展、人们对富裕生活的不断追求,自动售货机开始迅速普及。由于经济的高度成长,建立了消费物品的大量生产体制,同时需要与之相适应的大规模物流方式,满足这一需求的就是自动售货机和超级市场。在作为主力商品的饮料领域中,随着罐装咖啡的出现,诞生出了世界首例可销售冷、热饮料的冷热罐装饮料自动售货机,这向普及迈出了一大步。由于冷热罐装饮料自动售货机的推广,流通行业可提高设备设置的空间利用率,并能在全年内取得均衡的销售额。在原料加工后用纸杯等进行销售的杯式自动售货机领域中,从速溶咖啡机、普通咖啡机、甚至是能够在机器内部磨好咖啡豆后加牛奶的普通咖啡机,快速应对着消费者嗜好的变化。

1.4 自动售货机在国内的发展

随着我国经济的快速发展,人们的生活方式发生了巨大的变化,人们的生活节奏也越来越快!于是一种既节约时间又方便快捷的消费理念出现在了我们的面前,那就是自动售货。在这一思想的指导下,自动售货机应运而生,它的出现极大的方便了我们的生活。自动售货机是能根据投入的钱币自动付货的机器。自动售货机是商业自动化的常用设备,它不受时间、地点的限制,能节省人力、方便交易。是一种全新的商业零售形式,又被称为24小时营业的微型超市。能分为三种:饮料自动售货机、食品自动售货机、综合自动售货机。

在许多公共场所都能看到它的身影,比如,机场、车站、码头、地铁口、商业街、校园、办公写字楼、居民生活小区、游乐场以及一些大型的公司内部。

适销的商品更是五花八门、种类繁多,只要是各种标准化的商品,都可通过自动售货机予以销售。我们相信,随着我国经济的持续发展,人民消费水平的不断提高,对自动售货机的需求必将越来越多、越来越广泛。

现在,自动售货机产业正在走向信息化并进一步实现合理化。例如实行联机方式,通过电话线路将自动售货机内的库存信息及时地传送各营业点的电脑中,从而确保了商品的发送、补充以及商品选定的顺利进行。并且,为防止地球暖化,自动售货机的开发致力于能源的节省,节能型清凉饮料自动售货机成为该行业的主流。在夏季电力消费高峰时,这种机型的自动售货机即使在关掉冷却器的状况下也能保持低温,与以往的自动售货机相比,它能够节约10-15%的电力。进入21世纪时,自动售货机也将进一步向节省资源和能源以及高功能化的方向发展。

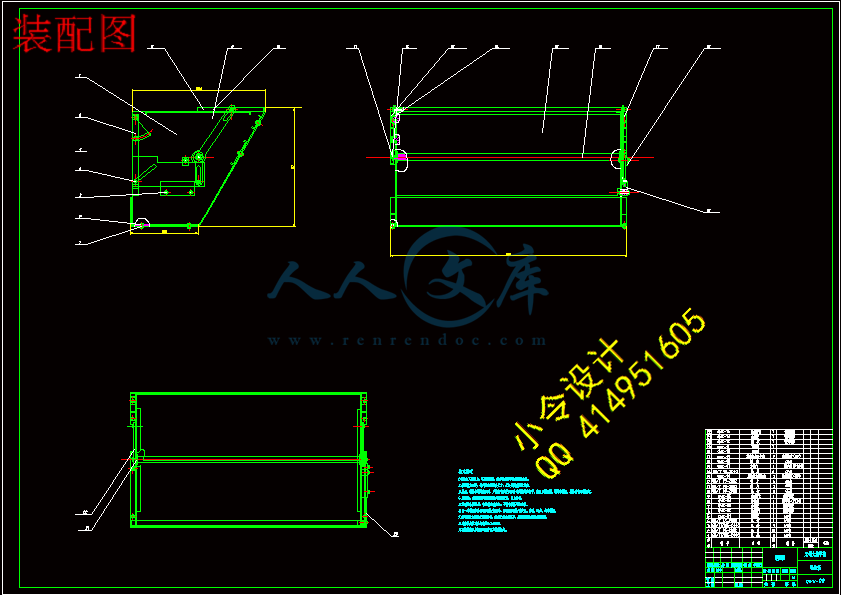

除此之外,自动售货机内部空间的布局也发生了很多变化,为了追求储物空间的最大化,必须控制其余部件所占的体积,取物箱的结构设计就是其中之一。传统取物箱结构的最大缺点就是高度过高,占用了自动售货机内部过多的空间,这主要是由防盗方式所引起的,现阶段市场上自动售货机的取物箱主要的防盗方式是使位于取物箱后部的防盗板向上翻转来封闭取物箱上部开口。此种方式的优点是实现方式简单可靠,缺点是在同等条件下取物箱实现功能所需的设计高度比较高(必须留出取物门与防盗板翻转所需的高度空间)不适宜现在越来越紧凑的设计要求。鉴于此类情况现需设计一新型的自动售货机用取物箱,此次我的毕业设计就是重新设计取物箱的防盗机构,该取物箱主要由取物箱箱体、取物门、防盗板、联动机构、运动辅助部件(滑动轨道等)组成。主要实现的运动过程是当向内推动取物门时,通过联动机构的传动使防盗板由后向前平移,并封闭整个取物箱上部开口,在整个运动过程中要使防盗板的平移速度尽可能的快于取物门的开启速度。

1.5 自动售货机在国外的应用

自动售货机是劳动密集型的产业构造向技术密集型社会转变的产物。大量生产、大量消费以及消费模式和销售环境的变化,要求出现新的流通渠道;而相对的超市、百货购物中心等新的流通渠道的产生,人工费用也不断上升;再加上场地的局限性以及购物的便利性等这些因素的制约,无人自动售货机作为一种必须的机器便应运而生了。

自动售货机在国外早已很普及,大街上、公寓里到处都是。在美国、日本和整个欧洲,自动售货机的应用领域已经扩展至小食品、冷热饮料、快餐、游戏软件、香烟、报纸、邮票、电话磁卡以及个人卫生用品等各个方面。其中,日本的自动售货机应用方面具有代表性。自动售货机已成为日本城市喧嚣街头的一个标志。这种机器已不仅限于销售香烟等各类商品,还提供许多新的服务功能,例如把零钱捐给某非政府组织,或者通过观看小屏幕播放的广告信息而获得打折等。通过一种新的自动售货机,消费者哪怕只购买一杯热咖啡也可获得折扣,因为在机器加热咖啡的过程中,液晶显示屏上会播放一段广告,消费者只需耐心看完广告就可获得打折。还有一些新机型可以接受向非政府组织的捐款。目前,日本街头已有1万多台可接受捐款的自动售货机,但需求量依然很大。还有一种机型,当身体健康处于危险状态的使用者按动按键时,机器就会发出警报声。此外,日本最主要的一家饮料分销商还与政府签订协议,推出了“灾害应急型”自动售货机。当地震等自然灾害发生时,中心电脑处理系统会向自动售货机发出指令,市民可从机器中免费提取饮料和食品。

1.6 自动售货机在国外的市场发展

目前,自动售货机作为一种不同于传统的零售方式进入四十五个国家市场。在这四十五个国家中,美国和日本发展最快。在国外主要是以饮料厂家引导,带动自动售货机的发展。作为世界上最大的自动售货市场,日本通过自动售货机出售的商品多达6000余种。在欧洲每台自动售货机日销售额达到50到100美元不等,以巴黎地铁车站为例,在各个站点总计摆放了1500台,每月销售额达600万法郎。美国自动售货机的零售营业额高达293亿美元,日本每个消费者每年在自动售货机上的消费金额达5.5万日元。全世界每年通过自动售货机销售商品的总额已达2000亿美元。

1.7 新型自动售货机的新增功能

1.7.1 多种货币识别功能:

电控系统可以配合纸币、硬币识别器增加代金券功能,可以识别纸质和硬币。

1.7.2 USB功能:

应用USB技术,使用一个优盘,就能轻松下载售货机的运营信息,然后使用PC机对下载的数据进行处理,便于运营商掌握不同地区、不同机器、不同商品的售卖情况。

1.7.3 无线网络运营管理功能:

将自动售货机当前运营的数据,包括系统状态、系统故障、料道故障、缺货情况、销售数据通过安装在自动售货机上的GPRS模块无线传输到售货机网络服务器,运营人员可以在任何一台联网的电脑上掌握售货机的这些信息,实现自动售货机的大规模运营和网络化管理。

1.7.4 带有摄像头:

一些装有监视摄像头的自动售货机已开始试用,它们除了可监控针对售货机的犯罪外,还对周边起到了警戒作用。此外,有关部门计划给自动售货机装上电子公告牌,使其能在自然灾害等紧急情况发生时,为公众提供信息服务。

1.7.5 语音功能:

自动语音叫卖功能,真正做到了代替营业员的叫卖,从而引起更多的消费者的关注。

1.7.6 故障诊断:

能自动快速诊断机器本身、纸币接收器、硬币接收器等模块的故障,并将故障信息提示操作者,便于有效的日常维护。

伴随收入水平的提高,人们追求灵活、方便、快捷以及自助式服务是自动售货机得以如此迅猛发展的主要原因。在发达国家自动售货机已经成为零售业一个不可分割的部分,特别是对青年一代,这种伴随其成长的前卫零售方式更可谓是一种新的消费时尚。现代都市生活的节奏日趋加快,追求方便、快捷的服务成为人们的一种时尚,以麦当劳、肯德基为代表的的西式快餐在我国的迅速发展就是很好的例子。随着对外开放的不断扩大,传统的零售业发展成百货商店、连锁超市、电视直销、厂家直销等多种方式并存的局面,极大地方便了人们的生活。

川公网安备: 51019002004831号

川公网安备: 51019002004831号