摘 要

随着公路交通的发展,我国的桥梁数量也迅猛增加。虽然在经济发展方面创造了良好的交通条件,但随之而来的检验维修问题将比较严重。由于桥梁的隐患问题而导致的交通事故往往是很严重的,因此,桥梁的安全越来越显得重要,从而产生了桥梁检测的问题,并由此衍生出一种新的检测工具--桥梁检测车。

我国未来几年的桥梁将保持着较快的速度发展,桥梁检测车在桥梁检测方面具有十分广阔的市场。

桥梁检测车是一种搭载检测设备和工作人员的改装汽车,因此安全显得特别重要。本文针对桥梁检测车的特点,以折叠臂式桥梁检测车为例子,结合液压控制系统,做如下研究:

1. 折叠臂式桥梁检测车的工作原理;

2. 对汽车设备的选型;

3. 支腿受力分析;

4. 液压控制系统。

关键词:桥梁检测车;折叠臂式;受力分析;液压控制

Abstract

With the development of highway traffic, the number of bridges in China is increasing rapidly. While in the aspect of economic development to create a good traffic conditions, but the subsequent inspection maintenance issues will be more serious. Due to the concerns of bridge caused by traffic accidents is often very serious, therefore, the safety of the bridge is more and more important, then produce the bridge detection problem, and thus derived a new detection tool - bridge inspection vehicle.

Chinese bridge in the next few years will remain relatively high speed development, bridge inspection vehicle has a very broad market in bridge inspection.

Bridge inspection vehicle is a kind of modified car carrying test equipment and staff, so is very important to safety. In this paper, according to the characteristics of the bridge inspection vehicle, with folding arm type bridge inspection vehicle car as an example, combined with the hydraulic control system, do the following research:

1. Folding arm bridge inspection vehicle automobile works;

2. Selection of automotive equipment;

3. Leg force analysis;

4. Hydraulic control system.

Keywords: bridge inspection vehicle; the folding arm type; leg force analysis; hydraulic control system

目 录

摘 要III

AbstractIV

目 录V

1 绪 论1

1.1 课题意义与背景1

1.1.1 课题意义1

1.1.2 课题背景1

1.2 桥梁检测车主要结构形式及国内外发展状况2

1.2.1 桥梁检测车主要结构形式2

1.2.2 国内外发展状况3

1.3 本文的主要研究内容5

2 桥梁检测车主要结构的设计6

2.1 折叠臂式桥梁检测车总设计方案6

2.2 总运动方案7

2.3 本章小结7

3 折叠臂式桥梁检测车的设备装置8

3.1 动力装置8

3.2 工作装置类型8

3.2.1 支腿机构8

3.2.2 举升机构9

3.2.3 回转机构9

3.2.4 作业平台的分析10

3.3 安全装置13

3.4 主题参数13

3.4.1 尺寸参数13

3.4.2 质量参数13

3.5 折叠臂式桥梁检测车地盘的选择14

3.6 本章小结14

4 举升机构与回转机构的设计15

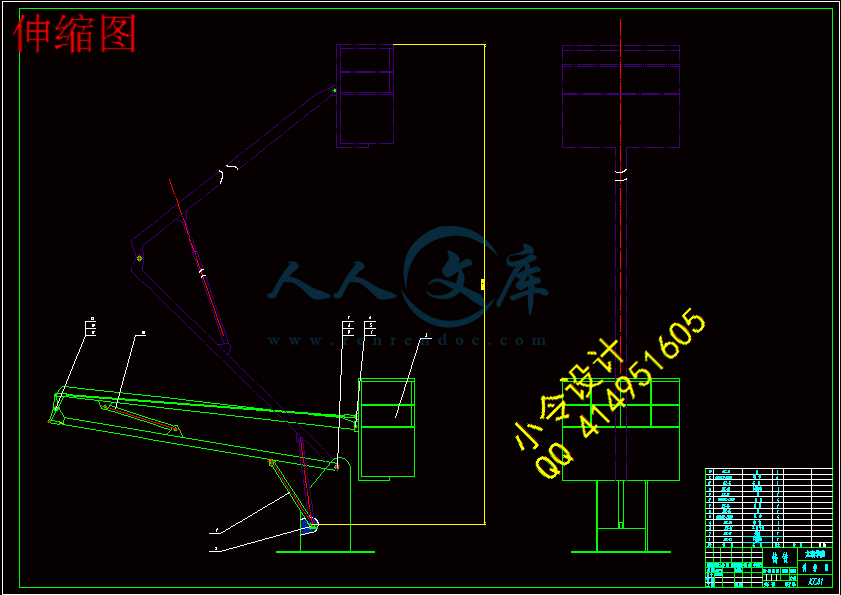

4.1 举升机构设计15

4.1.1 举升机构运动范围15

4.1.2 动臂的结构设计和主要尺寸15

4.2 回转机构设计15

4.2.1 回转机构设计16

4.2.2 确定圆柱滚子的允许载荷16

4.3 本章小结17

5 支腿机构和液压系统设计计算18

5.1 支腿机构设计计算18

5.1.1 支腿跨距18

5.1.2 支撑脚接地面积20

5.2 液压系统设计20

5.2.1 液压系统原理分析20

5.2.2 油缸选型21

5.2.3 液压泵的选型与计算22

5.2.4 油箱容积与管路内径计算23

5.2.5 液压系统参数设计24

5.2.6 液压泵的选型24

5.3 本章小结24

6 折叠臂式桥梁检测车稳定性能分析25

6.1 支腿压力计算25

6.2 本章小结27

7 结 论28

致 谢29

参考文献30

附 录31

1 绪 论

1.1 课题意义与背景

1.1.1 课题意义

桥梁是国家的重要基础设施,桥梁是经济建设中的重要组成部分。桥梁的建设需要大量的资金投入,在经济社会中又有着重要作用,使得人们对桥梁的安全性、耐久性越来越重视。与此同时,桥梁长时间的使用,由于各种外界环境的影响,桥梁结构将不可避免地产生自然老化、损伤积累等各种各样的疲劳和损伤,这些损伤都将导致严重的交通事故,造成巨大的经济损失和人员伤亡。此外,早期设计与社会发展的不协调,很多桥梁承载能力已经达不到社会的需求、桥面宽度不能满足巨大的车流量,这就需要对原有桥梁的结构安全进行检测评估,鉴定它的实际承载能力,以确定加固改造方案;同时新建桥梁也须进行承载力检测,以检验其施,工质量,为竣工验收提供科学依据[1]。

对桥梁的结构损伤采取有效手段进行监测、预测和控制,不但可以发现桥梁当时的结构是否损坏或服务功能是否降低外,确保交通枢纽的安全和正常运行,并可获得下列的效益:(1)准确提供桥梁信息;(2)提供桥梁损坏程度信息;(3)对桥梁有完整的记录;(4)(5)及时维修;(6)对新建设的桥梁提供有效的信息[2]。

对桥梁裂缝进行长期的监测和寿命评估是十分重要的。由于大多数桥梁的结构裂缝主要产生在桥梁底部,检测起来很困难,与此同时桥梁结构形式日趋发展向大型化和新颖化,使这个问题更加难于解决。由此,桥梁检测己经成为一个巫待探索的研究领域。

1.1.2 课题背景

目前我国桥梁检测存在的主要问题表现在:

①设备不先进:

对于跨线桥等旱地上桥梁,多采用在桥梁的下方搭架,然后人员在架上工作的方式进行,对于跨河桥则采用船上搭架的方式进行,部分过高的桥梁或船只没法靠近的桥梁基本上找不到好办法来解决检测检查问题。

②耗资高:

搭设脚手架需要耗费更多的人力、物力、财力,而且从搭设到开始使用,最后再拆除也耗时较长,并且影响进度。交通影响大:

③安全小:

工作人员站在支架上或者船上进行工作,容易造成事故。

④范围小:

由于受到桥梁的具体环境和搭设支架的限制,现有的办法很难对桥梁的每一部分进行检测,只能选择有代表性的部分进行检查,这样也就使降低了我们对桥梁使用状况的掌握,如果设备陈旧、手段落后自然无法反映桥梁的全部现状,影响了对桥梁的质量评估。

为了克服以上桥梁检测方式存在的问题,需要设计生产出一种可以为桥梁检测人员在检测过程中提供作业平台的专用设备。这就是通常大家所说的桥梁检测车,它实际上是一种用于桥梁检测维修作业的专用汽车,可以让作业人员随时移动位置,安全、快速、高效地进入作业位置。

有专家认为,由于“十五”期间及至少未来10年内我国公路及桥梁建设仍将保持较快的发展速度,所以预计我国今后大型桥梁检测车等在内的道路养护检测机械车将具有十分广阔的市场。

专用的桥梁检测车通过液压伸臂机构,将检测装置(摄像机、超声波探测器等)或工作人员承载到桥梁底面任意位置的有效探测距离内,检测桥梁底部缺陷或进行维修。这种桥梁底部缺陷的检测方式,具有高效率,安全性好,较强适应性、低功率消耗等优点[3]。

因此,本文研究的目的和意义在于:

1. 为研究和开发出新型智能化的检测装备,提供参考和基础。

2. 检测车析架结构小、工作臂长,可以穿过斜拉索,能准确、高效率地解决特大桥梁特别是斜拉桥底部缺陷的检测难题。

3.可将检测仪送到桥底的各个位置检测桥梁底部缺陷,取代人工探身桥底的检测方式,建立安全、可靠的无危险工作环境。

4.有效降低桥梁检测车的生产成本。

1.2 桥梁检测车主要结构形式及国内外发展状况

1.2.1 桥梁检测车主要结构形式

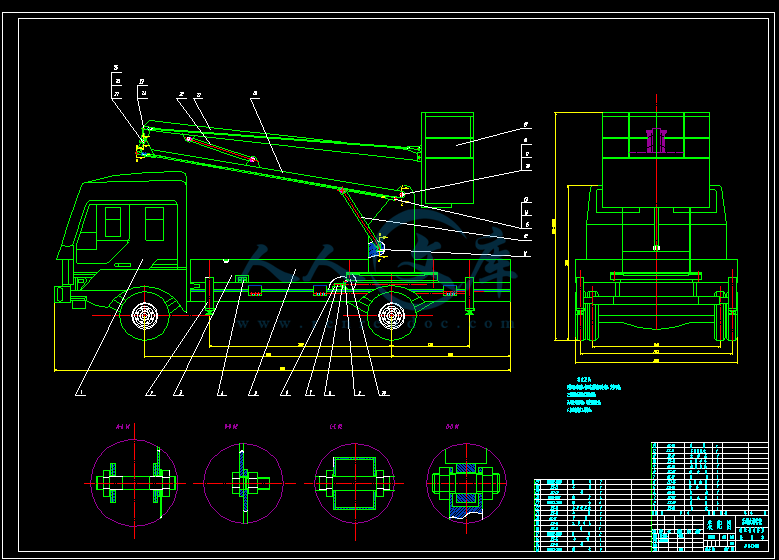

桥梁检测车是指装备有桥梁检测仪器和工作台,用于流动检测和(或)维修作业的专用汽车。它由汽车底盘和上装(上部工作装置)2部分组成。桥梁检测车最早出现在欧美,现在的装备技术已很先进,均采用电子液压控制,并配置有应急装置、稳定装置、遥控装置及发电设备。其上装结构型式有折叠臂式和桁架式2种。

(1)桁架式桥梁检测车

采用通道式工作平台,稳定性好,承载能力大,使用时检测人员能方便地从桥面进入平台或返回桥面,如配置升降机则可大大增加下桥深度。

(2)折叠臂式桥梁检测车

折叠臂式桥检车也叫吊篮式桥梁检测车,其结构小巧,受桥梁结构制约少,工作灵活,既可检测桥下也可升起检测桥梁上部结构,可有线、无线操作,灵活方便,有时候还可以做为高空作业车使用,价格相对析架式桥检车低[4]。

1.2.2 国内外发展状况

①国外状况:

桥梁检测车最早出现在欧美,美国HYDRA公司、Aspen Aerials(赛奔驰)公司,德国MOOG公司,意大利BAR工N公司等已有用于桥梁检测的检测车。现在的装备技术已很先进,均采用电子液压控制制,并配置有应急装置、稳定装置、遥控装置及发电设备。

意大利 BARIN(百灵):公司生产的 ABC 系列桁架式桥梁检测车最大水平工作范围6~23 m,最大下桥深度4~9.5m,最大承载质量300~800 kg,最大跨越宽度1.7~4.65m,最大跨越护栏高度2.0 ~5.4m∶AB系列折叠臂式桥梁检测车桥下最大水平距离6.5~22m,桥下最大垂直距离10~25.5m,桥上最大垂直距离8~20.5 m,吊篮最大载质量200~300kg[5]。

NIBL系列吊篮式桥梁检测车桥下最大水平距离12~16m,桥下最大垂直距离15~19. 5m,桥上最大垂直距离14~21m,吊篮最大载质量280 kg。

美国Aspen Aerials(赛奔驰):公司只生产折叠臂式桥梁检测车[6],主要产品型号有A~30,A~d0,UB~50,A~62,A~75,其桥下最大水平距离9.4~22. 8m,桥下最大垂直距离12.1~22m,桥上最大垂直距离9. 2~16.1m,吊篮最大载质量272~318 kg。所有Aspen Aerials桥梁检测车系列均可在无须装设液压支腿和配重的情况下进行平稳、安全、可靠地操作。

奥地利 PALFINGER (帕尔菲格)公司研发生产的 PA19000 型折叠臂式桥梁检测车,桥下吊篮最大水平伸长可达 16.2m,最大下桥深度 14m,最大承载质量 280 kg,吊篮向上最大举升高度 24.5m;美国 REACHALL 公司生产的 UB 系列折叠臂式桥梁检测车,桥下吊篮水平伸长可达到 13.2-18.6m,下桥深度可达15.8-21.3m,最大承载质量 272 kg,吊篮向上最大举升高度 10.7-14.4m。

②国内状况:

在我国,桥梁检测维修车尚处于研发的初级阶段。我国早在20世纪80年代末90年代初,由交通部公路规划设计院在北京起重机厂生产的QY~8型汽车起重机的基础上进行改造设计,最后以失败告终,后来国内又有几家单位研制也均以失败告终。最近几年,国内一批大型工程机械厂家开始从事桥梁检测车的研制,主要有徐工集团、湖南宝龙等,其产品和性能均能达到国外设备的标准。

徐工集团:徐工集团成立于1989年,主要从事工程机械的研发和生产,1997年由徐工集团液压气动机械公司、西安公路交通大学和河南省公路局联合成功研制出XZJ5140JQJ10型折叠臂式桥梁检测车,结束了我国无桥梁检测车的历史[7]。

吊篮式(折叠臂式)桥梁检测车主要有QJ07, QJ12,QJ16、QJ16L,其桥下最水平距离8~16. 37 m,最大下桥深度10~20m,最大承载质量100~200 kg。

2006年1月,徐工集团成功研制出18m桁架式桥梁检测车,标志着徐工跻身于全球4大桥梁检测车生产领域,与意大利BARIN,德国MOOG、美国凯捷公司并驾齐驱,进入桥梁检测车系列化的快车道。目前该集团己经形成9~22m桁架式系列产品,最大水平工作范围9~21. 9m,最大下桥深度6~8.5m,最大承载质量600~800kg,最大跨越宽度2.1~2.5m,最大跨越护栏高度2.0~3.2m。

湖南恒润高利有限公司湖南恒润高利有限公司,有多年的高速公路建设与养护经验,是以提供满足客户需求的高品质道路养护机械为目标,集产品研发、制造、营销为一体的专业化工程机械企业。

2009年2月,该公司根据市场行情和发展需要,参照德国MOOG桥梁检测车,在其基础上合理改进,井在吸取国内外桥梁检测作业车经验的基础上研制推出16 in桁架式桥梁检测作业车。该公司目前主要有HHR5250JQJ16,HHR5250JQJ08车型,其最大水平工作范围8~16 m,最大下桥深度7. 0m,最大承载质量600~700 kg,最大跨越宽度2. 1~2. 2 m,最大跨越护栏高度2.2m。

1.3 本文的主要研究内容

1. 根据桥梁检测的要求,确定桥梁检测车的总体方案和臂架机构的方案。

2. 设计出检测车臂架结构。

3. 液压控制操作方案。

4. 折叠臂式桥梁检测车的稳定性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号