摘 要

近年来,随着企业生产与管理的不断提高,越来越多的企业认识到物流系统的改善与合理性对企业的发展非常重要。堆垛机是自动化立体仓库中最重要的起重堆垛设备,它能够在自动化立体的巷道中来回穿梭运行,将位于巷道口的货物存入货格;或者相反取出货格内的货物运送到巷道口。

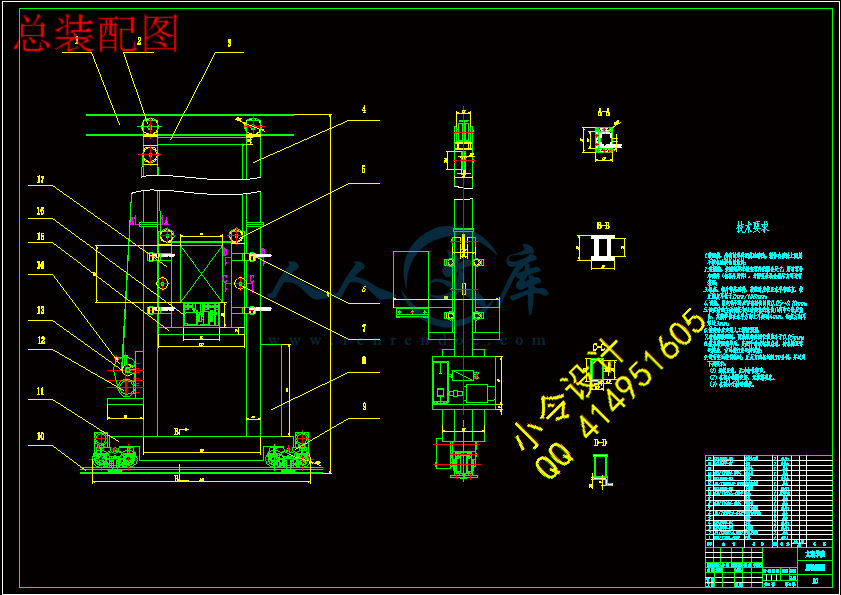

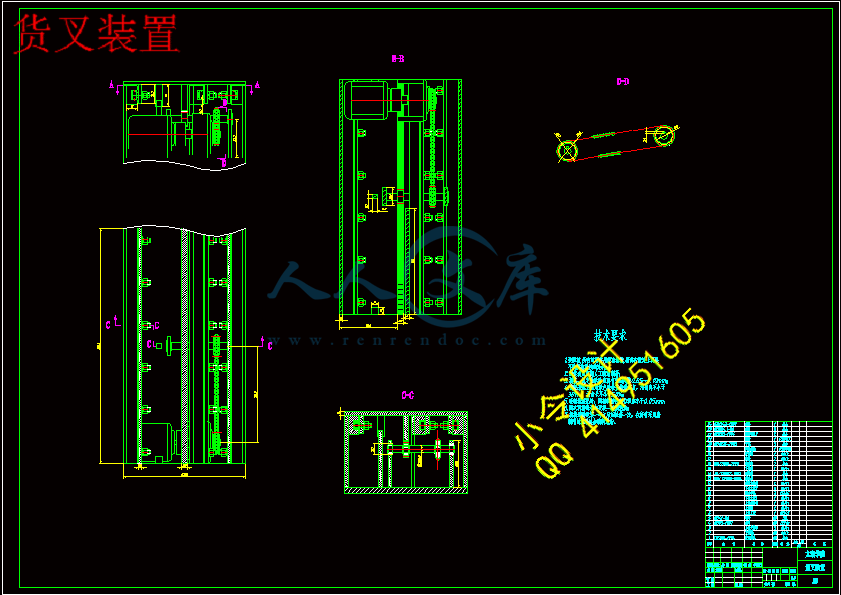

本文详细论述了在现代大多数企业中普遍使用的双立柱堆垛机的设计方案,文章的重点放在其两个部件:升降机构、货叉伸缩机构的设计上,并对安全机构和控制部分进行简单的选取和计算其中包含电机,减速器的选取,齿轮,齿条的计算,卷筒的计算,轴的校核,电器原理图的配置等。首先,提出各个机构的总体设计方案;其次,对各个机构的受力情况进行了分析并计算,然后估算初取值,再进行校核,最后确定各个实际值。

关键词:自动化立体仓库;堆垛机;升降机构;货叉伸缩机构

Abstract

In recent years, along with the unceasing raising of enterprise production and management, more and more enterprises know that thing flows out reasonability and the improvement of system, is very important for the development of enterprise. Stacker cranes is automation three-dimensional storehouse in most important take heavy crane pile up equipment, it can in the tunnel of automation cube in the shuttle operation of round trip, will locate in tunnel the goods of mouth stock goods shelf; or opposite take out the goods transit in goods shelf go to tunnel mouth.

This paper describes the majority of enterprises in the widespread use of modern double-column stacking machine design, the article focused on its two components: lifting mechanism, telescopic fork design of institutions, and security agencies and the control part simple selection and calculation including motor, reducer selection, gear, rack of calculation, the calculation of roll, axis calibration, electrical schematic diagram of the configuration. First, the proposed design programs of various agencies; Secondly, the force of the various agencies to conduct the analysis and calculation, and then estimate the initial value, and then checked, and finally establish the actual value.

Keyword:automation three-dimensional storehouse;stacker cranes;lifting mechanism; telescopic fork institutions

目 录

摘 要.......................................................................................................................................... III

ABSTRACT................................................................................................................................. IV

目 录........................................................................................................................................... V

1 绪论............................................................................................................................................ 1

1.1 研究的背景与内容............................................................................................................................. 1

1.1.1 概述............................................................................................................................... 1

1.1.2 有轨巷道堆垛机的发展现状及特点........................................................................... 1

1.1.3 有轨巷道堆垛机的类型............................................................................................... 2

1.1.4 巷道堆垛机的特点....................................................................................................... 5

1.2 设计的目的和意义.............................................................................................................. 5

1.3 设计的内容及要求.............................................................................................................. 5

1.4 设计参数.............................................................................................................................. 6

2.1 堆垛机三维运动速度的确定............................................................................................. 7

2.2 堆垛机各个部分的方案选择.............................................................................................. 8

2.2.1 堆垛机起升机构传动方式的选择........................................................................................... 8

2.2.2 堆垛机行走机构传动方式的选择............................................................................... 9

2.2.3 堆垛机机架的设计思路............................................................................................... 9

2.2.4 堆垛机货叉的设计思路............................................................................................... 9

2.2.5 堆垛机安全方案的确定............................................................................................. 11

2.3 堆垛机的技术参数............................................................................................................ 11

2.4 堆垛机的技术要求............................................................................................................ 11

3 堆垛机起升机构的设计.......................................................................................................... 15

3.1 起升机构的总体选型........................................................................................................ 15

3.2 卷筒的设计........................................................................................................................ 18

3.2.1 卷筒部件计算............................................................................................................. 18

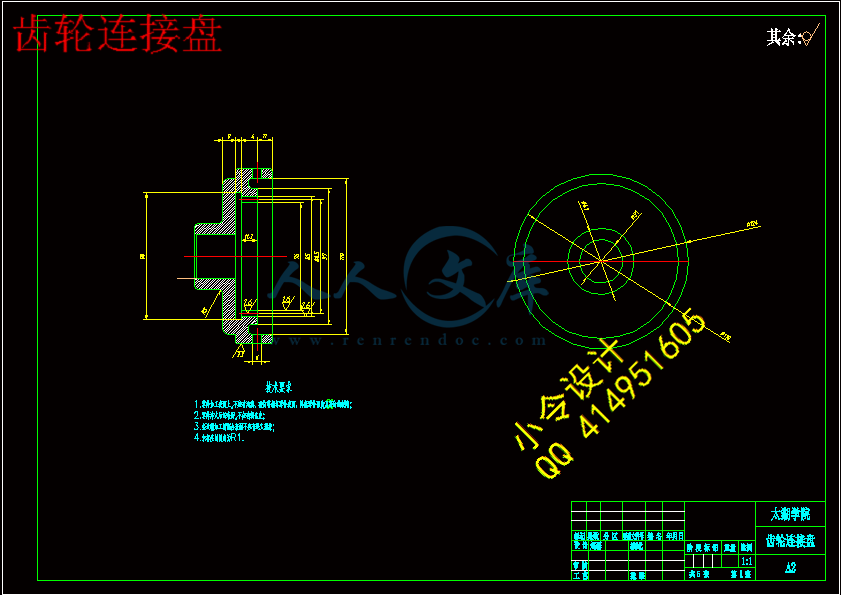

3.2.2 齿轮连接盘的计算..................................................................................................... 22

4 堆垛机行走机构和机架的选型设计...................................................................................... 25

4.1 堆垛机行走机构的选型设计........................................................................................... 25

4.2 堆垛机机架的选型设计................................................................................................... 27

5 堆垛机货叉的设计.................................................................................................................. 28

5.1 货叉传动装置的总体选型................................................................................................28

5.2 货叉传动齿轮、齿条的计算............................................................................................28

5.3 货叉传动链轮、链条的设计计算....................................................................................32

5.4 制动器的制动容量的设计................................................................................................34

6 堆垛机安全装置.......................................................................................................................35

6.1 防撞保护装置.................................................................................................................... 35

6.2 钢丝绳断绳保护装置........................................................................................................ 35

7 结论与展望.............................................................................................................................. 36

7.1 结论................................................................................................................................... 36

7.2 不足之处及未来展望........................................................................................................... 36

致 谢.......................................................................................................................................... 37

参考文献...................................................................................................................................... 38

1绪论

1.1 研究的背景与内容

1.1.1 概述

自动化立体仓库是实现物流系统合理化的关键。它具有空间利用率高、便于实现自动化管理、实时自动结算库存货物种类和数量、立体仓库信息库可以和中央计算机系统联网运行等许多优点,对加快物流速度、提高劳动生产率、降低生产成本都有重要意义,已开始应用于汽车、电子、医药、烟草、建材、邮电等许多行业。而堆垛机对立体仓库的出人库效率有重要影响,是立体仓库能否达到设计要求和体现其优点的关键设备之一。

有轨巷道堆垛起重机是随着立体仓库的出现而发展起来的专用起重机,是在高层货架的窄巷道内作业的起重机,通常简称为堆垛机。堆垛机是立体仓库中最重要的起重运输设备,可大大提高仓库的面积和空间利用率,是自动化仓库的主要设备,是代表立体仓库特征的标志。堆垛机的功能是堆垛机接受计算机指令后,能在高层货架巷道中来回穿梭,把货物从巷道口出人库货台搬运到指定的货位中,或者把需要的货物从仓库中搬运到巷道口出人库货台,再配以相应的转运、输送设备通过计算机控制实现货物的自动出人库。在立体仓库中的搬运设备有高位叉车、工业机器人、桥式堆垛机和有轨巷道式单双立柱堆垛机。有轨巷道式双立柱堆垛机由于效率高,高度可达30-40 m,便于实现无人操作,行走稳定,载货量大,噪声小,在目前的立体仓库中得到广泛应用。

1.1.2 有轨巷道堆垛机的发展现状及特点

随着经济全球化步伐的口益加快和信息技术的快速发展,传统行业和消费方式正发生着深刻的变化,物流在经济活动中的作用越来越受到企业的重视,物流人才的需求也在口益增长。目前,物流人才已经被列为我国12大类紧缺人才之一,有报道称“物流人才的需求已超过600万”。物流实验室的建设正是要搭建一座理论与实践的桥梁,目前,我国许多高校已经建立了物流实验室,据不完全统计,已经有160多所高校建立了自己的物流实验室。物流实验室为学生提供实训平台,深化学生对现代物流理论的理解,提高学生的操作能力,内融机械、电气、电子及计算机等技术于一体的综合技术,在这种技术中,不同领域和层次的知识与能力融会在一起。

另外,为了更好的模拟货物在自动化立体仓库各仓储单元内存储的物流过程,研究提高物流效率以及堆垛机性能和作业效率方法,许多物流研究中心业纷纷建立起来。山东大学现代物流控制实验中心是目前我国第一个现代的物流控制实验室,在物流调度、物流控制、机械手拣选控制和机器视觉的综合研究和开发应用方面目前处于国内领先地位。

图1.1仓储

1.1.3 有轨巷道堆垛机的类型

有轨巷道堆垛机可按其结构形式、支承方式和运行轨迹等进行分类,一般可分为以下几种类型:

(1) 按结构形式,分为双立柱有轨巷道堆垛机和单立柱有轨巷道堆垛机:

①双立柱有轨巷道堆垛机

双立柱有轨巷道堆垛机由两根立柱、上横梁、下横梁和带货叉的载货台组成,立柱、上横梁和下横梁组成一个长方形的框架,一般称为机架。立柱形式有方管和圆管两种,方管可兼作起升导轨,圆管需要附加起升导轨。这种堆垛机的最大优点就是强度和刚性都比较好,能快速起、制动,并且运行平稳。一般用在起升高度较高、起重量较大和水平运行速度较高的立体仓库中,其缺点是自重较大。其结构如图1.2所示。

图1.2双立柱有轨巷道堆垛机

②单立柱有轨巷道堆垛机

单立柱有轨巷道堆垛机的机架由一根立柱、下横梁和上横梁组成。立柱多采用型钢或焊接制作,立柱上附加导轨。整机重量较轻,消耗材料少,因此制造成本相对较低,但刚性稍差。由于载货台和货物对立柱有偏心作用,以及行走、制动时产生的水平惯性力作用,使单立柱有轨巷道堆垛机在使用上有较大的局限性。不适于起重量大和水平运行速度高的堆垛机。单立柱堆垛机的起升结构,普遍采用钢丝绳传动,由电机减速机驱动卷筒转动,通过钢丝绳牵引载货台沿立柱或起升导轨作升降运动。对于钢丝绳传动,传动和布置相对容易,但定位准确性稍差。其结构如图1.3所示。

图1.3单立柱有轨巷道堆垛机

(2) 按支承方式分类,有轨巷道堆垛机分为悬挂型和地面支承型。

①悬挂型有轨巷道堆垛机

悬挂型有轨巷道堆垛机悬挂在巷道上方的轨道上运行,其运行机构安装在堆垛机门架的上部。在地面铺设导轨,使门架下部的导向轮以一定的间隙夹在导轨的两侧,从而防止堆垛机运行时产生摆动和倾刹。悬挂式堆垛机有如下优点:在设计门架时,可以不考虑横向的弯曲强度,钢结构的自重可以减轻,加减速时的惯性摆动小,稳定所需的时间短;其缺点是维修和检查不方便。

②地面支承型有轨巷道堆垛机

堆垛机的运行轨道铺设在地面上,堆垛机用下部行走轮支承和驱动,上部导向轮用来防止堆垛机倾倒或摆动。和悬挂型有轨巷道堆垛机相比,这种堆垛机的立柱主要考虑轨道平面内的弯曲强度,因此,需要加大立柱在行走方向截面的惯性矩。由于驱动装置均装在

下横梁上,容易保养和维修。

(3) 按其运行轨迹形式不同,分为直线运行型堆垛机和曲线运行型堆垛机。

①直线运行型堆垛机

直线运行型堆垛机只能在巷道内直线轨道上运行,不能自行转换巷道。只能通过其他输送设备转换巷道,直线运行型堆垛机可以实现高速运行,能够满足出入库频率较高的立体仓库作业,应用最为广泛。

②曲线运行型堆垛机

曲线运行型堆垛机行走轮与下横梁是通过垂直轴铰接的,能够在环形或其他曲线轨道上运行,不通过其他输送设备便可以从一个巷道自行转移到另一个巷道。曲线运行型堆垛机在使用上有局限性,只适用于出入库频率较低的立体仓库。

本文研究的堆垛机是结构形式为双立柱,支承方式为地面支承型,并且其运行轨迹为直线型巷道堆垛机。

1.1.4 巷道堆垛机的特点

由于使用场合的限制,巷道堆垛机在结构和性能方面有以下特点:

(1)整机结构高而窄,其宽度一般不超过储料单元的宽度,因此限制了整机布置和结构选型。

(2)金属结构件除应满足强度和刚度要求外,还要有较高的制造和安装精度。

(3)采用专门的取料装置,常用多节伸缩货叉或货板机构。

(4)各电气传动机构应同时满足快速、平稳和准确。

(5)配备可靠的安全装置,控制系统应具有一系列连锁保护措。

1.2 设计的目的和意义

仓储自动化建设是一项系统工程,物资储运作业自动化是其重要的内容。实现仓库物资储运作业自动化,仓储机械设备、设施及管理、信息、人才系统配套、协调发展是重要的发展趋势。

通过引入计算机、自动控制技术和人工智能等高新技术对仓储机械的技术该做,仓储机械的技术性能将较大提高。载重量大、机动性强、操作方便、可维修性好的叉车、无人叉车、牵引车、托盘运输车、堆高车、堆垛机、码垛机、管道输送机、带状输送机、自动拣选机等先进的装卸搬运机械设备将广泛应用于仓储系统。

本设计通过设计用于仓储货架的堆垛机,完成堆垛机水平行走机构、起升机构、载货台及货叉机构、机架和电气设备的设计,能及时、准确地把物品自动送到指定位置,从而加深对堆垛机的认识与了解。

1.3 设计的内容及要求

有轨巷道堆垛机的内容包括:

第一,分析、论述目前堆垛机堆垛的原理、方法,堆垛机的设计思路,探讨各种解决途径。

第二,论述本设计采用的方法、原理及可行性,进行结构设计、运动学计算和强度计算。

第三,堆垛机的工作方式及货物识别控制原理。

第四,绘制堆垛机总装图和主要零部件图。

有轨巷道堆垛起重机的设计要求包括:

1.结构简单、操作方便。

2.堆垛方式准确可靠。

3.结构紧凑坚固,使用维护方便,外形美观。

1.4 设计参数

立体仓库为8巷道16排40列7层

堆垛机总高度:8m 总长度:3.1m 总宽度:1m

堆垛机额定起重量300kg

行走最大速度130m/min(2.2m/s)

升降最大速度30m/min(0.5m/s)

货叉速度9m/min(0.15m/s)

加减速度:升降0.6 行走0.6 伸缩0.2

货架上下7层,层高1100mm

货架每层40格,格宽900mm

货箱尺寸:长×宽×高=600×500×800mm

货格尺寸:长×宽×高=900×600×1100mm

宽度方向为货叉叉取方向。

川公网安备: 51019002004831号

川公网安备: 51019002004831号