摘要

本文旨在探索板材坡口机的总体结构设计,即板材坡口机的设计,又称板材坡口机设计。当前我国板材坡口机技术已经有了一定的发展,而且逐渐趋于自动化。

本文根据板材坡口机的工作原理和基本结构,初步设计板材坡口机。在此基础上通过对此题目的分析以及对一些相关书籍和文献的查阅,进一步研究了板材坡口机的总体结构设计。本文所设计的板材铣边用于电厂中铝板焊接前的坡口成型,板材坡口机的设计重点应在于液压系统和板材坡口机的铣削系统的设计。已完成的主要工作可以概括为以下四方面:

1.对课题的来源、选题的目的、以及板材坡口机在国内外发展的形势及所存在的问题进行了相关的论述。

2.阐述了板材坡口机的一般结构,然后根据自身的需求选取适当的结构组件。简易的叙述了总体方案设计。

3.对液压系统的基本概念、特点、应用以及基本工序做了简要的介绍,进而分析了板材坡口机技术的现状和发展方向。

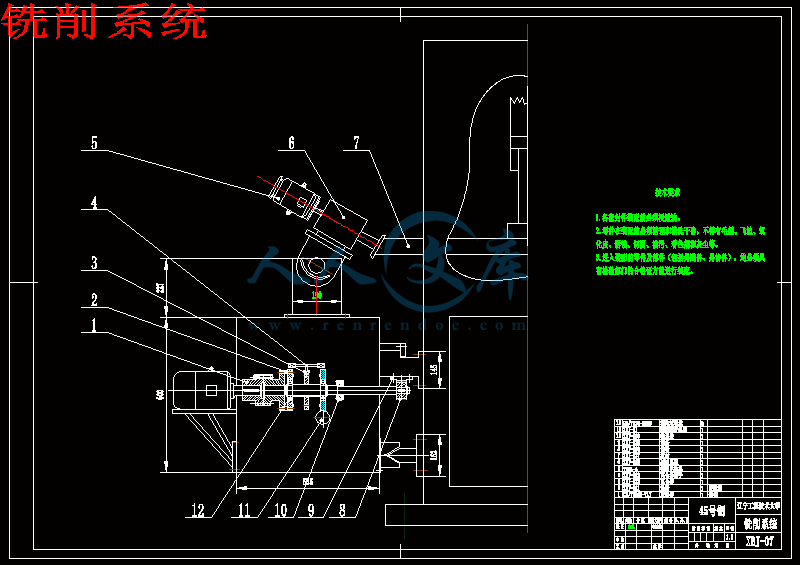

4.对本设计的重点-板材坡口机的铣削系统进行设计。分析了铣削控制系统的过程,进而对铣削件进行了工艺分析,为板材坡口机铣削系统设计奠定了基础,最后对板材坡口机铣削系统重要的各个尺寸参数进行了校核。

本文通过研究设计板材坡口机的基本原理,获得了大量有关设计板材坡口机的要领。论文的完成对进一步完成生产性设计和探索设计板材坡口机过程有一定的参考价值。

关键词:坡口机;剪板机;传动;液压;自动化

Abstract

This article thesis is aimed at exploring the overall structure design of plate edge milling machine, that is the design of plank stuff edge milling machine, also called the design of board groove machine.At present,the design of plank stuff edge milling machine already has the certain development,and gradually tends to automation.

According to the principle of work and basic structure of plank stuff edge milling machine,the present thesis designs the plank stuff edge milling machine.On the base of these works, through regarding this topic analysis and consulting to some correlation books and literature, were further make clear that the overall design of plank stuff edge milling machine. This present thesis designs the plank stuff mill uses in the power plant before thealuminum sheet welding bevel to take shape. Designs should lie in with emphasis the design of the hydraulic system and milling system .

The main work achieved are summed up as following:

1.The related summary was made on the source and goal of task , Domestic and foreign development situation,existence problem.

2.The related summary was made on the general structure,then according to own demand selection suitable structure module.And a simiple narration was made on the overall design of plank stuff edge milling machine.

3.The related summary was made on the basic concept,characteristic,application and essential working procedure,and was further analysis the present situation and development direction.

4.The related summary was made on this design key point-milling system. Analysis was made on milling control system,and was further craft analysis the milling components.this has laid the foundation for the milling system of plank stuff edge milling machine.Finally,it has carried on the examination on each improtant size parameter of plank stuff edge milling machine.

In this paper a lot of experimental data about main point of plank stuff edge milling machine were acquired by studying the basic principle.This paper also will provide guidance for industrialization and researching plank stuff edge milling machine process.

Keywords: plank stuff edge milling machine; board groove machine; guillotine shear;transmission; hydraulic pressure;automation

目录

前言1

1 绪论2

1.1 课题来源2

1.2 课题的设计目的及意义2

1.3 与课题相关的国内外研究现状分析2

1.3.1 板材坡口机在国内的发展情况2

1.3.2 板材坡口机在国外的发展情况4

1.3.3 对板材坡口机行业在国内发展的建议5

1.4 刨边机与坡口机的优缺点6

1.5 铣边与剪边工艺的比较7

1.5.1板边加工在焊接工艺中的必要性7

1.5.2 板边加工工艺常用的带钢板边加工工艺7

1.5.3 圆盘剪剪边工艺7

1.5.4 粗铣+精铣工艺8

1.5.5 单台铣边工艺8

1.5.6 圆盘剪剪边+单坡口机铣边工艺8

1.5.7 板材焊接质量好8

1.5.8 板材成材率高8

1.5.9 易加工厚板9

1.5.10 铣边坡口参数9

1.5.11 铣边工艺对工作条件的要求9

1.5.12 存在问题10

1.5.13 结论10

1.6 主要设计内容和预期结果11

1.6.1 设计内容11

1.6.2 预期结果11

2 板材坡口机的总体结构概述12

2.1 板材坡口机的结构12

2.2板材坡口机的总体方案设计13

3 控制系统的选择及设计14

3.1 控制系统的选择14

3.2 液压传动系统的设计14

3.2.1 液压缸主要参数的确定14

3.2.2 缸筒壁厚和外径计算15

3.2.3 液压缸的强度校核16

3.3 液压元件的选择18

3.4 液压系统的性能验算20

4 板材坡口机铣削系统设计21

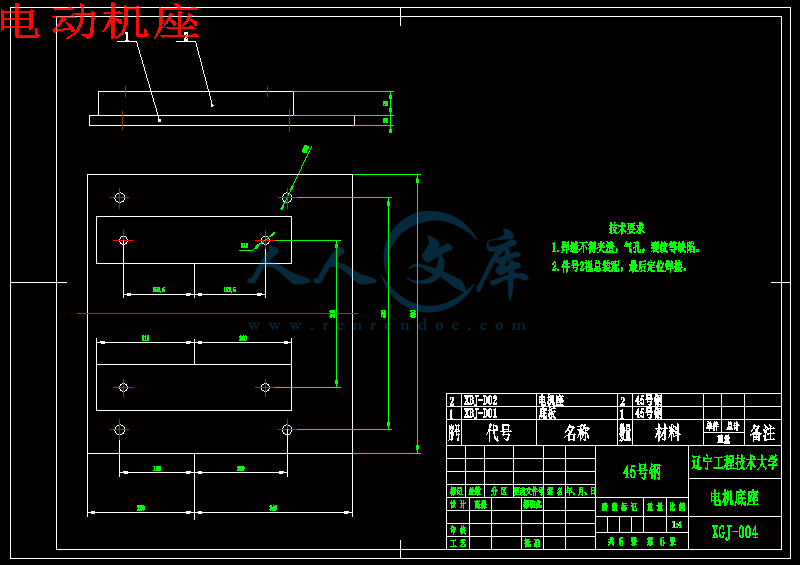

4.1 电动机的选择21

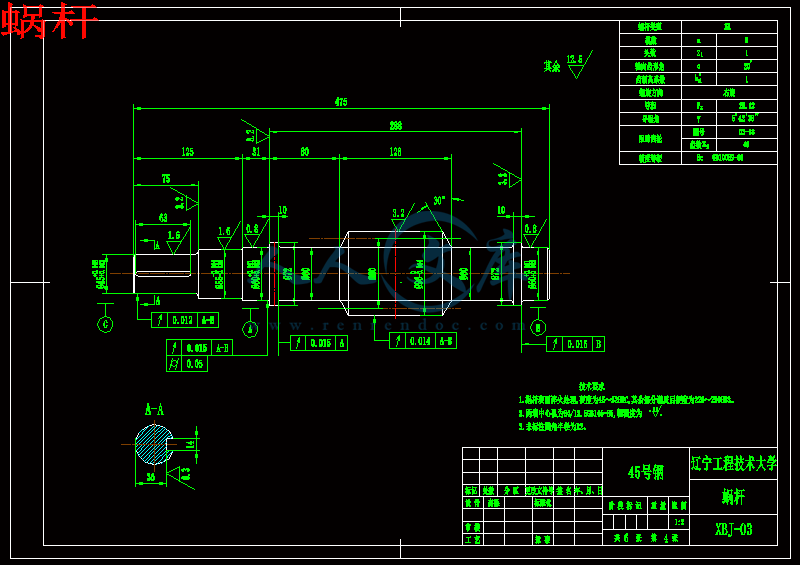

4.2轴的设计21

4.2.1轴的转矩强度计算21

4.2.2 轴的结构设计21

4.3 齿轮的选择及计算23

4.4 导轨的设计24

4.4.1 导轨的功用24

4.4.2 直线运动导轨的特点24

4.4.3 普通滑动导轨的特点24

4.4.4 V型导轨的选用25

5 经济性分析26

6 结论27

致谢28

参考文献29

附录A30

附录B38

川公网安备: 51019002004831号

川公网安备: 51019002004831号