摘 要

冲压成型是金属成型的一种重要方法,它主要适用于材质较软的金属成型,可以一次成型形状复杂的精密制件。本课题就是将石化、化工、电力等行业的法兰密封结构中的垫片作为设计模型,将冷冲模具的相关知识作为依据,阐述冷冲模具的设计过程。

本设计对指定工件进行的单工序模设计,利用Auto CAD软件对制件进行设计绘图。明确了设计思路,确定了冲压成型工艺过程并对各个具体部分进行了详细的计算和校核。如此设计出的结构可确保模具工作运用可靠,保证了与其他部件的配合。并绘制了模具的装配图和零件图。

本课题通过对工件的冲压模具设计,巩固和深化了所学知识,取得了比较满意的效果,达到了预期的设计意图。

关键词:冲压成型;单工序模;弯曲模;冲孔

Abstract

Stamping is an important method of metal forming, it is mainly applied to relatively soft metal forming, can be a molding of precision parts of complex shape. This topic is to petrochemical, chemical, electric power industries in the flange gasket sealing structure as a design model, Die related knowledge as a basis to explain the design process of Die.

The design of the suspension by the single operation dies design, the use of Auto CAD software to design parts drawing. Clear design ideas, determine the process of stamping and forming part of the various specific details of the calculation and verification. The structure of such a design die is used to ensure reliability, ensure coordination with other components. And draw the mapping of the mold assembly and part drawings.

Suspension of the project through the stamping die design, consolidate and deepen the knowledge, and achieved satisfactory results, to achieve the desired design intent.

Keywords: press forming; single operation die; bending die;punching

目录

摘 要III

AbstractIV

目录V

1 绪论1

1.1 本课题的意义目的1

1.2 本设计的技术要求1

2 软管夹加工工艺规程设计2

2.1 要求2

2.1.1 标准要求2

2.1.2 软管夹所用材料,镀层厚度的要求3

2.1.3外观要求3

2.1.4 夹紧范围3

2.1.5 试验方法3

2.1.6 检验规则3

2.2 钢带加工工艺规程设计3

2.2.1 落料冲孔4

2.2.2 冲斜排孔4

2.2.3 冲标记4

2.2.4 孔部成型4

2.2.5 打磨毛刺4

2.2.6 检验4

2.3 壳体加工工艺规程设计5

2.3.1 壳体落料5

2.3.2 打弯脚冲标记5

2.3.3 成型5

2.3.4 弯脚成形6

2.3.5 检验6

2.4 蜗杆加工工艺规程设计6

2.4.1 下料7

2.4.2 墩头7

2.4.3车外圆及各台肩7

2.4.4铣槽7

2.4.5 搓丝7

2.4.6 去毛7

2.4.7 渗碳淬火7

2.4.8 镀锌7

2.4.9 检验7

2.5装配工艺规程设计7

2.5.1 钢带与壳体的装配工艺设计7

2.5.2 钢带,壳体与蜗杆的装配工艺设计7

2.6 工艺工序卡片及装配工序卡8

3 钢带冲孔模具设计11

3.1 钢带冲孔工艺分析11

3.1.1产品尺寸精度,粗糙度,断面质量分析11

3.1.2 产品材料分析11

3.2 钢带冲压工艺方案的确定11

3.2.1 钢带冲压工艺分析11

3.3 钢带冲孔模结构的确定12

3.3.1 模具的形式12

3.4 钢带冲压工艺计算12

3.4.1排样12

3.4.2 计算冲压力12

3.4.3 计算模具压力中心14

3.4.4计算刃口尺寸15

3.5 钢带冲孔模主要零件设计计算18

3.5.1 凹模的设计计算18

3.5.2 根据凹模尺寸查标准典型组合19

3.5.3 固定板的设计计算19

3.5.4 卸料板的设计计算20

3.5.5 弹性元件的设计计算20

3.5.6凸模的设计计算21

3.5.7 钢带冲孔模其他零件的设计和选用22

3.5.8 钢带冲孔模闭合高度的计算22

3.5.9 压力机的选择22

3.5.10 其他23

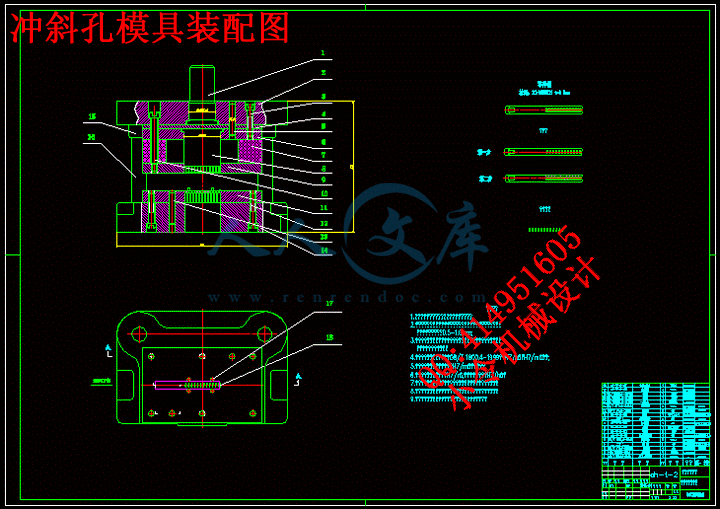

4 钢带冲斜孔模具的设计24

4.1 钢带冲斜孔工艺分析24

4.1.1产品尺寸精度,粗糙度,断面质量分析24

4.1.2 产品材料分析24

4.2 钢带冲斜孔工艺方案的确定24

4.2.1 钢带冲斜孔工艺方案分析24

4.3钢带冲斜孔模结构的确定25

4.3.1 模具的形式25

4.3.2 定位装置25

4.3.3 卸料装置25

4.3.4 导向零件25

4.4 钢带冲压工艺计算25

4.4.1 排样25

4.4.2 计算冲压力26

4.4.3 计算模具压力中心27

4.4.4计算刃口尺寸28

4.5 钢带冲斜孔模主要零件设计计算29

4.5.1凹模的设计计算29

4.5.2根据凹模尺寸查标准典型组合30

4.5.3 固定板的设计计算30

4.5.4 卸料板的设计计算31

4.5.5 定位零件的设计计算31

4.5.6凸模的设计计算32

4.5.7钢带冲斜孔模其他零件的设计和选用33

4.5.8 钢带冲斜孔模闭合高度的计算33

4.5.9压力机的选择34

4.5.10其他35

5 壳体落料模具的设计36

5.1 壳体落料工艺分析36

5.1.1产品尺寸精度36

5.1.2 产品材料分析36

5.2 壳体落料工艺方案的确定36

5.2.1 壳体落料工艺方案分析36

5.3 钢带冲孔模结构的确定37

5.3.1 模具的形式37

5.3.2 定位装置37

5.3.3卸料装置37

5.3.4 导向零件37

5.4 钢带冲压工艺计算37

5.4.1 排样37

5.4.2 计算冲压力38

5.4.3 计算模具压力中心39

5.4.4计算刃口尺寸39

5.5壳体落料模主要零件设计计算41

5.5.1凹模的设计计算41

5.5.2 根据凹模周界尺寸选择典型组合42

5.5.3 固定板的设计计算42

5.5.4卸料板的设计计算43

5.5.5 定位零件的设计计算44

5.5.6凸模的设计计算45

5.5.7钢带冲孔模其他零件的设计和选用45

5.5.8 钢带冲孔模闭合高度的计算45

5.5.9 压力机的选择46

5.5.10 其他47

6结论与展望48

6.1结论48

6.2不足之处及未来展望48

1 绪论

1.1 本课题的意义目的

毕业设计是对每个即将毕业的大学生都具有十分重要的意义:首先是对学生的知识能力进行一次全面的考核,其二是对学生进行科学研究基本功的训练,培养学生综合运用所学知识独立地分析问题和解决问题的能力,为以后工作或撰写专业学术论文打下良好的基础。所以我们需要抓住这次机会好好的锻炼自己的能力。

1.2 本设计的技术要求

本次毕业设计的题目是“I型软管夹冲压装配工艺设计及部分模具设计”专题是“冲压装配工艺设计”和“模具设计”,课题来源于无锡市海江汽车部件有限公司。本次设计的任务是:不锈钢I型软管夹的各个零件工艺规程的制定;完成生产软管夹的其中三种模具的设计。技术要求:要求模具工作平稳,结构简单,工作可靠,装卸方便,维修及调整便利,加工精度应符合零件图要求。

设计课题涉及到课题的分析、资料的查询、资料摘录,整理收集的资料。然后深入无锡市海江汽车部件有限公司生产一线向使用者、设计者学习,具体的了解模具的外形、模具的大致结构,并记录了如何有所改进,最后确定设计的方案。以及模具体的结构图,并进行相关零件的选型计算。设计该模具要求我们具备基本的实践知识和经济意识因此考虑到:模具的实用性以及企业资源。

本课题的设计由本人独立完成,故本人的设计说明书包括加工钢带的其中两种模具以及加工壳体的模具,并附有装配工艺卡片。

川公网安备: 51019002004831号

川公网安备: 51019002004831号