目录

摘要3

Abstract4

绪论5

1零件分析6

1.1零件工艺性分析6

1.2 结构分析7

1.3精度分析7

2.冲裁工艺方案的确定7

3零件工艺计算8

3.1搭边值的计算8

3.2刃口尺寸计算8

3.3排样计算9

3.4冲压力计算10

3.5压力中心计算10

3.6冲压设备的选用10

5模具零部件结构的确定11

5.1标准模架的选用11

5.2卸料装置中弹性元件的计算11

5.3其他零部件结构12

6 模具装配图12

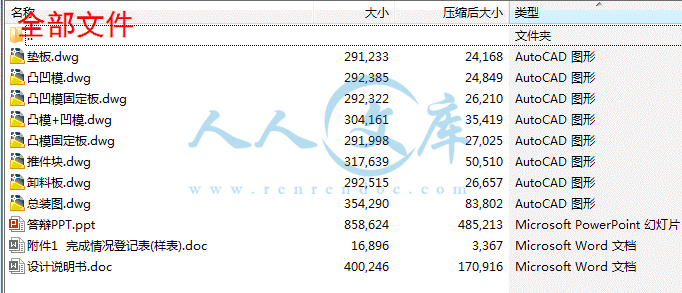

7 模具零件图12

8 小 结24

9 参考文献25

10谢辞26

摘要

十五期间,中国的模具行业的年增长率为20%。。在2005的销售额达到61000000000元,同比增长25%,在全球排名第三;;模具出口大较快增长,表示模具水平和竞争力剧增。;模具产品结构更高档的,复杂的,精度提高,模具的份额为30%,寿命长。。目前,国内模具制造商超过30000,员工800000人左右,53400000000元模具产值。

我国模具行业的发展在地域散步上有不平衡性,东南沿海地域成长快于中西部地区。南方的发展快于北方。2004,广东省模具工业,首先在模具行业,产值,模具制造业的产值和大约40%的国家销售会计。

我国模具市场空间巨大。一个汽车模具需要几千副模型。几百套铸造模具。

在我国,模具是一个新型的产业,带动了国内机械行业的发展,从大型工厂到小作坊,模具的影响力不言而喻,当前征服部门极力发展汽车行业,首当其冲的就是模具,模具生产效率高。产品质量也非常好,

Abstract

During the fifth, China's mold industry growth rate of 20%. . Sales in 2005 reached 61 billion yuan, an increase of 25 percent, ranking third in the world;; mold large and rapid growth in exports, which means that the mold level and competitiveness surge. ; Mold product structure is more upscale, sophisticated, precision can be improved, 30% share of the mold, long life. . Currently, the domestic mold manufacturers more than 30,000 employees around 800,000 people, 53.4 billion yuan mold production.

Development of China's mold industry in the geographical imbalance walk there, the southeast coastal areas to grow faster than the Midwest. Rapid development in the South in the north. 2004, Guangdong mold industry, first in the mold industry output value reached 18.5 billion yuan, mold manufacturing output and about 40 percent of the national sales accounting.

China's mold huge market space. A car needs a few thousand die deputy models. Hundreds of sets of casting molds.

In China, the mold is a new industry, led to the development of the domestic machinery industry, from small workshops to large factories, the impact force of the mold goes without saying that the current authorities tried to conquer the development of the automotive industry, the first is the mold, the mold production efficiency high. Product quality is also very good,

绪论

模具行业已经经过漫长的成长,当前处于提升升阶段,目前,模具行业属于过渡,所有企业将面临更多的机遇与挑战。模具产业想要有所提升,必须不断注入科研资金,提高科技分量,创造出具有代表竞争力的产品。 加强产品科研强度,才可以真正改善当前的竞争模式。

当前中国的模具销售模式单一,产业不集中,售后服务没有跟上,很大程度上限制了模具的发展

中国模具工业的崛起需要不断进行技术革新,管理改革,为了获得激励。许多企业走弯路,为了能消除弊端,国家已经出台政策,模具的低效性逐渐在中国铸造业的管理缺陷的消除。

产业的兴起是中国模具行业的特点,模具工业的崛起,还有很大的发展空间。

川公网安备: 51019002004831号

川公网安备: 51019002004831号