摘要:本设计进行了落料、冲孔、拉深复合模的设计。文中简要概述了冲压模具目前的发展状况和趋势。对产品进行了详细工艺分析和工艺方案的确定。按照冲压模具设计的一般步骤,计算并设计了本套模具上的主要零部件,如:凸模、凹模、凸模固定板、垫板、凹模固定板、卸料板、导尺、挡料销、导正销等。模架采用标准模架,选用了合适的冲压设备。设计中对工作零件和压力机规格均进行了必要的校核计算。此外,本模具采用始用挡料销和钩形挡料销挡料。模具的冲孔和落料凸模分别用不同的固定板固定,便于调整间隙;冲孔凹模和落料凹模则采用整体固定板固定。落料凸模内装有导正销,保证了工件上孔和外形的相对位置准确,提高了加工精度。如此设计出的结构可确保模具工作运行可靠和冲压产品大批量生产的要求。

关键词: 复合模 校核 冲孔 落料 拉深。

Abstract:The design of the blanking and punching, drawing composite modulus design. This paper briefly outlined the Stamping Die current development status and trends. The product of a detailed analysis and the identification process. Stamping die design in accordance with the general steps to calculate and design the sets on the main mold parts, such as : punch and die. Punch plate, plate, Die plate and dump plates I. feet behind the sales, marketing and other derivative is. Die-standard model planes, to choose a suitable stamping equipment. Design work on the parts and specifications will press for the necessary checking calculation. In addition, the die block used only with marketing materials and Crook block behind the marketing materials. Punch and Die blanking punch were different plate fixed to facilitate adjustment gap; Punch and Die blanking die is used overall fixed plate. Blanking punch contents is a derivative sales, and guarantee the workpiece and the shape of the holes in the relative position accurately, improve processing accuracy. So the structure is designed to ensure reliable operation of die stamping products and mass production requirements.

Keywords : composite modules Check Punching Blanking Drawing.

目录

1.绪论············································· 1

1.1冲压技术概念··································· 1

1.2我国模具技术的发展趋势························· 2

1.3 复合模的主要特点······························· 7

1.4 模具CAD技术·································· 7

1.5 本课题的来源及主要任务························· 8

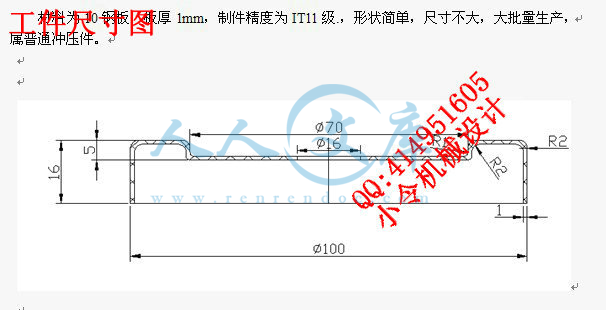

2.冲压件的工艺分析······························ 9

2.1工艺方案的分析和确定····························10

2.1.1毛坯直径D的计算······························10

2.1.2 拉深次数n的计算······························10

2.2 工艺方案的确定··································10

2.3计算各工序压力、压力中心、初选压力机·············11

2.3.1冲裁力的计算···································12

2.3.2.初选压力机····································12

2.3.4.确定压力中心··································13

2.4冲压工序·········································13

2.5模具结构设计·····································13

2.5.1模具结构选择···································13

2.5.2模具工作部分的尺寸和公差的确定·················14

2.5.3 模具结构设计·································· 15

2.6整修工序·········································16

3.结论···············································19

4.致谢···············································20

5.参考文献·········································· 21

1 绪论

1.1 冲压技术概论

冲压是利用安装在冲压设备(主要是压力机)上的模具对材料施加压力,使其产生分离或塑性变形从而获得所需零件(俗称冲压件或冲件)的一种压力加工方法。冲压工艺与模具、冲压设备和冲压材料构成冲压加工的三要素。冲压是一种先进的金属加工方法,在国民经济的加工工业中占有重要的地位。与机械加工及塑性加工和其它方法相比,冲压加工无论在技术方面还是经济方面都具有许多独特的优点,主要表现如下[1]:

(1) 冲压一般没有切削碎料产生,材料的消耗较少利用率高,一般为70%~85%,易实现机械化和自动化;

(2) 在形状和尺寸精度方面的互换性较好。一般情况下可直接满足装配和使用要求;

(3) 冲压可加工的尺寸范围大、形状复杂的零件,而这些零件用其它方法是不可能或很难得到的,如薄壳件;

(4) 被加工的金属在冲压加工过程中产生加工硬化,金属内部组织得到改善,机械强度有所提高,所以冲压件刚度强度较好;

(5) 冲压时由模具保证了冲压件的尺寸与形状精度,且一般不破坏冲压材料的表面质量,而模具的寿命一般较长,所以冲压件的质量稳定,互换性好,具有“一模一样”的特征;

(6) 在大量生产的条件下,产品的成本低,经济效益较高;

(7) 冲裁过程能耗较低。

由此可见冲压制得的零件具有表面质量好重最轻成本低的优点。所以冲压在现代工业生产中,尤其是大批量生产中应用十分广泛。相当多的工业部门越来越多的采用冲压方法加工产品零件,如汽车、农机、仪器、仪表、电子、航空、航天、家电及轻工业等行业。在这些工业部门中,冲压件所占的比重相当的大,少则60%以上,多则90%以上。不少过去用锻造、铸造和切削加工方法制造的零件,现在大多数也被质量轻刚度好的冲压件所代替。有些机械设备往往以冲压件所占比例的大小作为评价结构是否先进的指标之一[2]。

工业发达国家对冷冲压生产工工艺的发展是很重视的.不少国家(如美国、日本等)模具工业产值己超过机床工业。从这些国家钢材构成可以看出冷冲压的发展趋势。钢带和钢板占全部品种的67%,充分说明冲压这种加工方法己成为现代工业生产的重要手段和发展方向。

冲压技术的发展特征是:

(1)冲压成形科学化、数字化和可控化;

(2)突出“精、省、净“三大优势;

(3)冲压成形可以实现全过程控制;

(4)产品从设计开始即进入控制,考虑工艺;

(5)冲压生产的灵活性和柔性。

川公网安备: 51019002004831号

川公网安备: 51019002004831号