目 录

第1章 绪论1

1.1 精冲概述1

1.2 精冲的原理及特点1

1.2.1 精密冲裁的原理1

1.2.2 精密冲裁的特点2

1.3 精冲技术的国内外研究状况和发展2

1.3.1精冲技术在国际上的应用2

1.3.2精冲技术在国内的发展3

1.4 课题研究的目的意义及论文主要研究内容4

第2章 精密冲裁工艺与精密冲裁模的设计5

2.1 精密冲裁工艺5

2.1.1 精冲的分类5

2.1.2 精冲材料8

2.1.3 精冲零件的工艺性9

2.1.4 精冲零件的质量10

2.1.5 精冲工艺的应用范围11

2.2 精密冲裁模的结构和设计12

2.2.1 精冲模具结构12

2.2.2 精冲模具设计的基本原则12

2.2.3 精冲设备13

2.3本章小结13

第3章 汽车制动器调节齿板精冲模设计14

3.1冲压工艺设计14

3.1.1冲压件工艺分析14

3.1.2 排样设计15

3.1.3 冲压工艺力计算16

3.1.4 工作零件刃口尺寸计算18

3.1.5 压力中心计算18

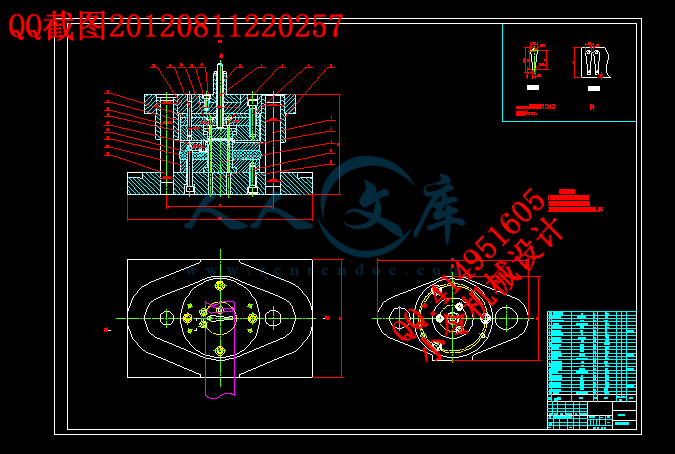

3.2 模具结构设计19

3.2.1 凸模设计19

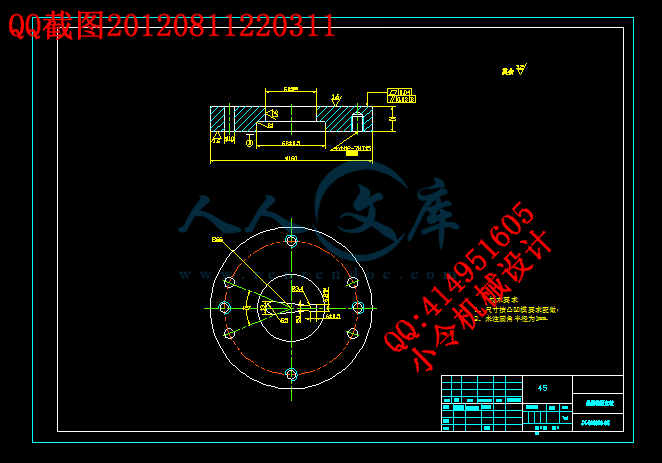

3.2.2 凹模的设计20

3.2.3 卸料板的设计21

3.2.4 推件装置23

3.2.5 挡料销24

3.2.6 橡胶25

3.2.6支撑零件设计25

3.2.7压力机的选用27

3.3 模具制造装配要点28

3.4 本章小结29

第4章 结论30

参考文献31

致谢32

摘 要

精冲是冲压中一种比较先进的金属加工方法,它在汽车、航天等领域正在发挥越来越重要的作用。随着工业技术的发展,精冲的作用会在更多领域得到广泛应用。

本说明书通过对汽车制动器调节齿板工艺的正确分析,在查阅了大量相关资料后,设计了一套精密冲压模具。本文从工艺分析开始对整个设计过程进行了详尽的介绍,叙述了模具成型零件的设计与加工工艺过程,主要零件的工艺参数的选择与计算,压力中心的计算,精冲压力机的选择等。本设计中对模具的结构进行了一定的改良和创新,使之更易操作和维修,在不影响工件质量的前提下,降低了生产成本。有利于精冲模具的普及和发展。

关键词:汽车制动器调节齿板;精冲;模具设计

Abstract

The fine flushing which is widely applied in the automotive and aerial industries is a new machining method .Whose principle was presented in this paper .The brake adjustment toothed rack mold of an automobile was designed with some refinement and originality that offered an ease of use and maintenance and a decrease in cost with the same precision . This paper also elaborated the entire design process including structure design and process design .

This instruction booklet through to the automobile brake adjustment toothed rack craft correct analysis, after has consulted the massive correlation data, has designed set of precise ramming molds. This article started from the craft analysis to the entire design process to carry on the exhaustive introduction, narrated the mold to take shape the components design and the processing technological process, the important components craft parameter choice and the computation, The selection of the process parameter and the press as well as some relative calculations ---such as the pressure center, was also performed. In this design has carried on the certain improvement and the innovation to the mold structure, causes it to be easier to operate and the service, in does not affect the work piece quality under the premise, reduced the production cost. Is advantageous to fine flushes the mold the popularization and the development.

Key Words: The automobile brake adjustment toothed rack;The essence flushes;Mold design

第1章 绪论

1.1 精冲概述

精密成形技术具有高效、精密、节能、少费料等特点,国外称之为净形加工或近似净形加工(net shape or near net shape)。作为精密成形技术之一的精冲技术是通过精冲模具,在专用压力机或经过改装的通用压力机上,使板料在三向压力状态下沿所需轮廓进行纯剪切分离,能得到断面光洁、垂直、平整度好、精度高的板状精密轮廓零件。精冲零件的尺寸可达IT6~IT9,孔距公差为0.101~0.105毫米,剪切面粗糙度为Ra0.4~Ra1.6,光亮带可达板厚的100%[1]。精密冲裁工艺代替切削加工来制造盘状精密轮廓零件(如齿轮、凸轮、链轮及齿板等),加工效率可以提高十几倍以上,大大降低了生产成本,是目前制造技术发展的方向之一。

川公网安备: 51019002004831号

川公网安备: 51019002004831号