摘 要

建筑地点:阳泉开发区 construction Site: YangQuan

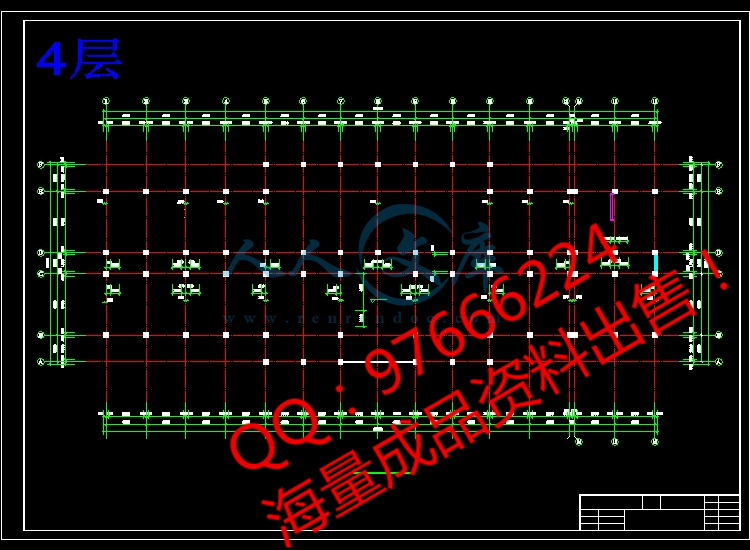

结构形式:框架结构 construction Systen: Frame structure

建筑面积:5880 m2 floor Area: 5880m2

层数/高度:5层/21m stories/Height: 5stories/21 m

主要用途:教学 、办公 main Use: teaching、office

框架结构 frame structure

现浇混凝土 cast-in-place concreate

条形基础 spread footings

屋面板 roof plate

正截面 normal section

根据教学要求入手,从“灵活使用”的角度出发,绿化与建筑相结合,改善外部购物环境。内部采用大、中、小不同的空间尺寸以及斜线、曲线等不同的要素,构成了富于层次流动感强的浓郁的气氛。

综合楼是一座以教学为主的集办公、娱乐等功能的建筑物。在设计理念上,力求在整体造型上突出现代、新颖、做到简洁、明快、虚实相接、刚柔相济、给人以蓬勃向上的感觉。设计上采用拉索点式玻璃幕墙等新技术、新材料,创造一个满足功能、符合环境、有鲜明现代性的建筑形象。透过通透落地玻璃幕墙,使室内、室外空间相互交融,同时作为窗口,起到了一定的美化市容的作用。

"Flexible use"and combination of greening and building latgely improve its outside shopping environment.In the inside,laige,medium and small--sized spice,togethei with the various building elemenrs like diagonal and curve,creates a dense atmosphere.Xin'Plaza conveys the traditional charm of modern architecture,and effectively billboatd.

Geri Plaza is an integrated including shopping,restaurants,entertainment cente and offices.In terms of design concept,the designers tried to fully materialize both the general features offirst-class modem shopping mall and the unique identity of FriendshipShopping Mall.In terms of overall form,this shopping mall gives priority to modernism and novelty ---its concise and lively shape conveys a sense of vigor and aggression.Steel strure,aluminum plate outerdecoration and suspended cable point glass curtain wall and other mew technique and materials are introduced into thedesign,giving prominence to the characteristic of steel structure.The harmonious combination of steel,glass and aluminum pate creates an idantity of modem atchitecture that can not only meetthe functional requirements but also assort with the envuribnebt.The transparentfloor glass curtain wall makes the outdoor and indoor space meet.And it is also a window,showing the passersby the indoor scenery of the shopping mall.

第一部分 建筑设计说明

1 建筑概况

1.1 工程简介

1.1.1 设计题目:阳泉学院综合楼

1.1.2 设计依据:本工程系根据阳泉市规划部门批准之方案和有关《建筑设计规范》进行设计的。

1.1.3 设计要求:建筑耐久年限二级(50年),耐火等级二级,抗震设防为7度。

1.1.4 建筑地点及地基平面图:

本建筑位于阳泉市开发区,场地地形平坦。其拟建基地平面图见附图

1 建筑场地

1.1.5 结构形式:框架结构

1.1.6 建筑规模:

本建筑为五层、三跨框架结构。建筑面积大约为5880mm2,其中教室面积大约为1800mm2,办公区面积大约为400mm2,实验室面积大约为1000mm2,其他房屋面积大约为1000mm2,层高为4.2m;

1.2 建筑技术条件资料

1.2.1 气象条件:

基本风压0.40KN/m2 基本雪压0.35KN/m2。

1.2.2 工程地质条件(见设计任务书)

1.3 建筑方案简要说明

1.3.1 朝向:

教学楼就是为学生提供正常教学的场所空间。由于它的功能要求,空间特征及交通组织等,故此建筑选择坐北朝南的朝向。

1.3.2 本楼各层均采用自然排风。

1.3.3 采用自然和人工采光相结合的方式。

1.3.4 开间模数:

根据我国自己的实践建议采用三种开间模数,即3M.采用这相关模数的优点有三:

①能满足商场购物的正常要求,与工业化生产紧密结合,

②考虑结构的互换性,有利于预制构件的大量生产

③与我国统一的标准窗扇采用0.3m为倍数尺度结合起来,故本建筑采用建筑模数为3m。

1.3.5 进深: 采用6.9m进深,能够满足教学的要求。

1.3.6 层高: 根据资料层高取4.2 m。

1.3.7 顶棚: 均采用粉底。

1.3.8 地面:教学楼地面均采用水磨石做法。

1.3.9 墙体: 采用加气混凝土空心砌块,内外墙厚均为250厚,对于小于500的墙垛用粘土砖砌。

1.3.10 安全疏散和防火分区:

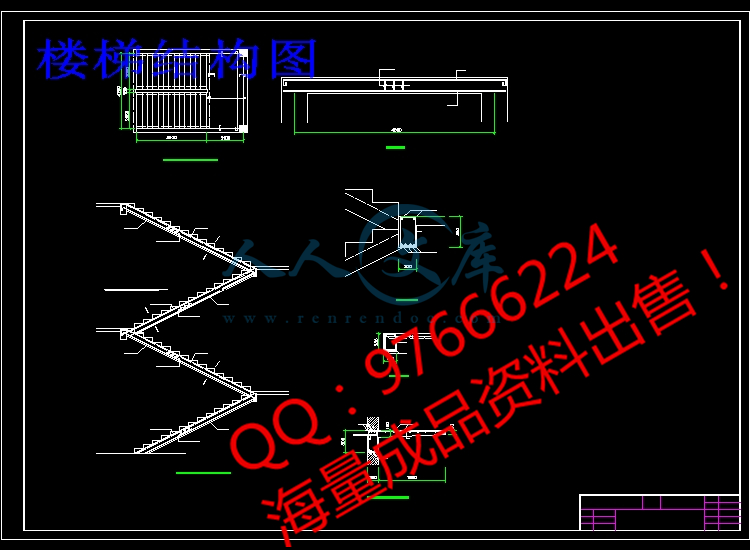

本建筑要求耐火等级为Ⅱ级,《规范》要求防火分区间 的最大允许面积为1000mm2,每层设一个防火分区每层最大面积864mm2,均符合防火要求。对房间超过60mm2以上的均设置两个以上的门。各层均设消防栓。底层开一个大门,楼内设有两部楼梯,以满足人流的疏散与防火要求。

1.3.11 走廊宽度

决定宽度的因素包括交通量、建筑物长度及门的开启方向,为防止突发性火灾或减少火灾危害程度,人流量较大,故取2.4m宽度。

1.4 建筑物的优缺点

本建筑根据不同要求做了不同的设计布置与处理。对防震、通风、采光等都做了具体的设计安排。对人流的疏散、防火、照明、等都做了比较合理的布置,总的来说是合理的。

川公网安备: 51019002004831号

川公网安备: 51019002004831号