您若下载本次文件,将获得(CAD图纸+word文档),以下为本次文件的目录及部分图纸截图。【需要其他机械类资料可以联系QQ97666224】

摘 要

模具是制造业的基础工艺设备,被广泛应用于制造业的各个领域。在我国制造业不断发展的今天,模具制造显得越来越重要,社会对模具的需求和相关技术人员需求也越来越大。

本次毕业设计的题目是塑料盒连接架模具设计,材料为ABS,该模具采用侧浇口一次分型实现浇道冷凝的自动填充,型芯采用镶拼式,采用斜导柱和抽芯机构成型构成塑件两侧轮廓,动模和定模两侧分别配以型芯、滑块、锁紧楔和定位销等机构,采用顶杆顶出塑件。

本设计的模具结构合理,操作便捷,方案合理,经济适用。

关键词:注塑模;型芯;抽芯机构;定位销;顶杆

Abstract

Mold is the foundation of equipment manufacturing industry, are widely used in various fields of manufacturing industry. In the continuous development of China's manufacturing industry today, mold manufacturing becomes more and more important , the social demand for mold and related technical personnel demand is also growing.

The topic of this graduation design is the design of the injection mold for food packaging box handle hinge plate, the material is ABS, the mold adopts automatic filling side gate a typing achieved runner of condensation, core by inlaying, formed by plastic parts of on both sides of the contour of oblique guide pillar and core pulling mechanism of forming, dynamic simulation and both sides are respectively matched with a mold core, slide, wedge lock and a positioning pin mechanism, using the top out of plastic parts.

The die structure design is reasonable, convenient operation, reasonable, economical.

Key Words: injection mold; core; core pulling mechanism; locating pins; the top rod

目 录

1 绪 论.....................................................................................................................1

1.1 题目背景意义................................................................................................1

1.2 塑料工业简介................................................................................................1

1.3 我国塑料模现状............................................................................................2

1.4 塑料模发展趋势............................................................................................3

1.5 本文主要研究内容........................................................................................3

2 制品的分析.........................................................................................................4

2.1 制品的简介....................................................................................................4

2.1.1 对制品的分析包括以下几点.............................................................4

2.1.2 本设计中塑件各项要求.....................................................................4

2.2 制品的工艺性及结构分析............................................................................4

2.2.1 结构分析.............................................................................................4

2.2.2 成型工艺分析.....................................................................................5

2.2.3 材料的性能分析.................................................................................6

2.3 注射成型过程................................................................................................7

2.3.1 材料的注射工艺参数.........................................................................8

2.3.2 材料的使用性能.................................................................................8

2.3.3 材料主要性能指标.............................................................................8

3 拟定模具的结构形式......................................................................................9

3.1 确定型腔数量和排列方式............................................................................9

3.2 模具结构形式的确定....................................................................................10

3.2.1 单型腔单分型面模具.........................................................................10

3.2.2 多型腔多分型面模具.........................................................................11

3.3 注射机型号的确定........................................................................................11

3.3.1 注射机的使用原则.............................................................................11

3.3.2 有关制品的计算.................................................................................11

3.3.3 注射机型号的确定.............................................................................12

3.3.4 注射机及各个参数的校核.................................................................12

3.4 分型面位置确定............................................................................................12

3.5 浇注系统的设计............................................................................................13

3.5.1 系统设计原则.....................................................................................14

3.5.2 主流道的设计.....................................................................................15

3.5.3 冷料穴的设计.....................................................................................16

3.5.4 浇口的设计.........................................................................................17

3.5.5 浇注系统凝料的脱出机构.................................................................18

3.6 脱模推出机构的确定....................................................................................19

3.6.1 脱模推出机构的设计原则.................................................................19

3.6.2 制品推出的基本方式.........................................................................20

3.6.3 带螺纹塑件的脱模机构.....................................................................20

3.6.4 脱模斜度的确定.................................................................................20

3.7 抽芯机构的设计............................................................................................20

3.7.1 侧向抽芯的分类及特点.....................................................................21

3.7.2 脱模阻力的计算.................................................................................21

3.7.3 抽拔距的计算.....................................................................................22

3.7.4 液压抽芯机构及斜导柱侧抽机构.....................................................22

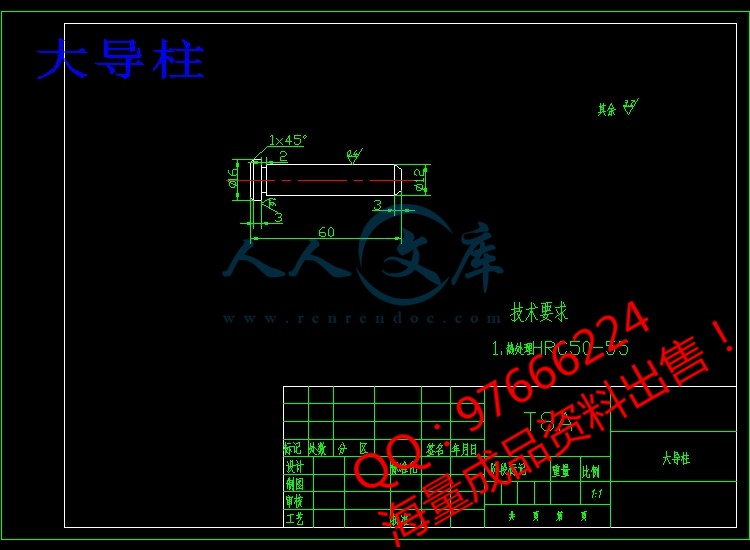

3.8 合模导向机构的设计....................................................................................23

3.8.1 导向机构的分类.................................................................................23

3.8.2 导柱导向机构设计要点.....................................................................23

3.8.3 本设计中导柱的设计.........................................................................24

3.9 排气系统的设计............................................................................................24

3.9.1 排溢设计.............................................................................................24

3.9.2 引气设计.............................................................................................24

3.9.3 排气系统.............................................................................................24

3.9.4 该模具的排气方式.............................................................................24

3.10 温度调节系统的设计..................................................................................25

3.10.1 加热系统...........................................................................................26

3.10.2 冷却系统...........................................................................................27

3.11 模架的确定和标准件的选用......................................................................28

3.11.1 定模座板.........................................................................................27

3.11.2 定模板、动模板.............................................................................28

3.11.3 定模型腔、动模型腔.....................................................................28

3.11.4 模脚.................................................................................................28

3.11.5 动模座板.........................................................................................29

3.11.6 推板固定板.....................................................................................29

3.12 成型零件的结构设计与计算......................................................................30

3.12.1 凹模的设计.....................................................................................31

3.12.2 凸模的设计.....................................................................................32

3.12.3 型腔侧壁的计算和校核.................................................................32

4 塑料模材料的选用及技术要求...................................................................34

4.1 塑料模材料的性能要求................................................................................34

4.2 塑料模材料选材原则....................................................................................34

4.3 模具的精度要求............................................................................................34

4.3.1 模具零件的公差与配合原则.............................................................36

4.3.2 模具形位公差的选用.........................................................................36

5 模具工作过程....................................................................................................38

5.1 成型前的准备................................................................................................38

5.1.1 原料的检验与预处理.........................................................................38

5.1.2 料筒的清洗.........................................................................................38

5.1.3 嵌件的预热.........................................................................................38

5.1.4 脱模剂的选用.....................................................................................38

5.2 注射过程........................................................................................................39

5.3 脱模过程........................................................................................................39

5.4 制品的后处理................................................................................................39

5.4.1 退火处理.............................................................................................39

5.4.2 调湿处理.............................................................................................40

6 总 结..................................................................................................................41

参考文献..................................................................................................................42

致谢............................................................................................................................43

川公网安备: 51019002004831号

川公网安备: 51019002004831号