1 概述 ……………………………………………………………………………1

2 冲压件工艺………………………………………………………………………6

2.1冲压件工艺分析……………………………………………………………6

2.2材料力学性能……………………………………………………………9

2.3确定冲压工序……………………………………………………………9

2.4 编制工艺方案及模具类型结构……………………………………………9

3 冲裁工艺计算……………………………………………………………………11

3.1 排样设计基本内容…………………………………………………11

3.2排样方法……………………………………………………………11

3.3 板料排料设计……………………………………………………………12

3.3.1搭边……………………………………………………………12

3.3.2 料宽……………………………………………………………… 13

3.4 冲裁力的计算 ……………………………………………………………15

3.5冲压设备的选用……………………………………………………………16

3.6压力中心的计算 …………………………………………………………17

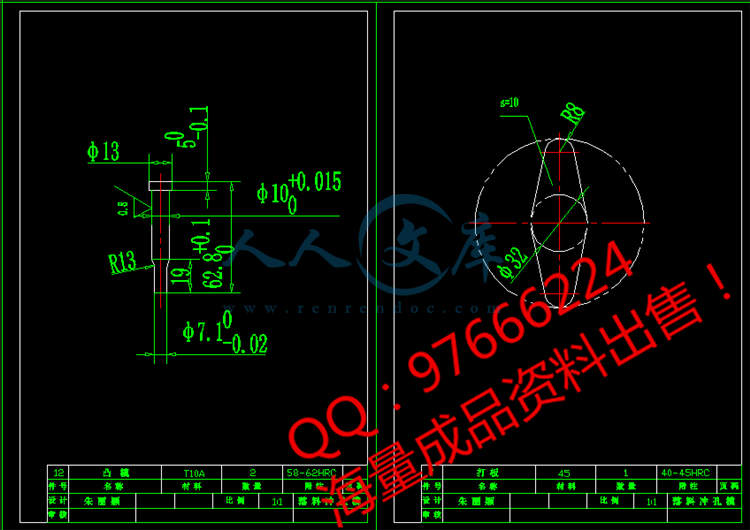

3.7凸模、凹模、凸凹模的尺寸与结构设计的确定…………………………18

3.7.1凸模与凹模刃口尺寸的确定 …………………………………… 18

3.7.2凸模、凹模、凸凹模的结构设计…………………………………20

3.8主要零部件结构和设计…………………………………………………24

3.8.1定位零件…………………………………………………………24

3.8.2卸料零件…………………………………………………………24

3.8 3导向零件……………………………………………………………24

3.8.4弹性装置…………………………………………………………24

3.9落料冲孔复合模总装配图…………………………………………25

4 冲孔模……………………………………………………………………………26

4.1 冲裁力的计算……………………………………………………………26

4.2 冲压设备的选用…………………………………………………………26

4.3凸模、凹模的尺寸计算…………………………………………………26

4.4 模架的选择………………………………………………………………27

4.5主要零部件结构和设计…………………………………………………28

4.5.1定位零件…………………………………………………………28

4.5.2固定零件…………………………………………………………28

4.5.3导向零件…………………………………………………………28

4.5.4弹性装置…………………………………………………………28

5 毕业设计总结……………………………………………………………………29

致谢…………………………………………………………………………………30

参考文献 ……………………………………………………………………………31

川公网安备: 51019002004831号

川公网安备: 51019002004831号