解放牌中型货车后轮鼓式制动器设计

摘 要

鼓式制动也叫块式制动,现在鼓式制动器的主流是内张式,它的制动蹄位于制动轮内侧,刹车时制动块向外张开,摩擦制动轮的内侧,达到刹车的目的。

制动系统在汽车中有着极为重要的作用,如果失效将会造成灾严重的后果。制动系统的主要部件就是制动器,在现代汽车上仍然广泛使用的是具有较高制动效能的蹄—鼓式制动器。本设计就摩擦式鼓式制动器进行了相关的设计和计算。在设计过程中,以实际产品为基础,根据我国目前进行制动器新产品开发的一般程序,并结合理论设计的要求,首先根据给定车型的整车参数和技术要求,确定制动器的结构形式、制动器主要参数及其选择,然后计算制动器的最大制动力矩、同步附着系数、制动力与制动力分配系数、制动器的结构参数与摩擦系数等,并在此基础上进行制动器主要零部件的结构设计。最后,完成装配图和零件图的绘制。

关键词:鼓式制动器;制动力;最大制动力矩;结构参数;摩擦系数

The design of jiefang medium-sized truck rear wheel drum brake

Abstract

Drum brake, also known as block-type brake, drum brakes, now within the mainstream style sheets, and its brake shoes located inside the brake wheel, brake brake blocks out when open, the inside wheel friction brake, to achieve the purpose of the brakes.

In the vehicle braking system has a very important role, failure will result in disaster if serious consequences. The main parts of the braking system is the brake, in the modern car is still widely used in high performance brake shoe - brake drum. The design of the friction drum brakes were related to the design and calculation. In the design process, based on the actual product, according to our current brake factory general new product development process, and theoretical design requirements, the first model of the vehicle according to the given parameter and the technical requirements, determine the brake structure and, brake main parameters and their choice, and then calculate the maximum braking torque of brake, the synchronous adhesion coefficient and brake force and brake force distribution coefficient, the structural parameters of the brake and friction coefficient, deformation shoe, brake effectiveness factor, braking deceleration, wear characteristics, brake temperature, etc., and in this brake on the basis of the structural design of major components. Finally, assembly drawings and parts to complete mapping.

KeyWords:drumbrake; braking force; maximum braking torque; Structure parameters; the coefficient of friction

目 录

1 绪论1

1.1汽车制动器发展的概况1

1.2研究制动器系统的意义2

1.3制动系应满足的要求2

1.4本设计要完成的内容2

2 鼓式制动器的结构形式与选择3

2.1鼓式制动器的结构形式4

2.1.1领从蹄式制动器4

2.1.2双领从蹄式制动器4

2.1.3双向双领从蹄式制动器4

2.1.4单项增力式制动器5

2.1.5双向增力式制动器5

3 制动器的主要参数及其选择6

3.1制动力与制动力分配系数6

3.2同步附着系数的计算10

3.3制动器最大制动力矩11

3.4制动器的结构参数与摩擦系数12

4 制动器的主要零件的结构计算15

4.1制动鼓15

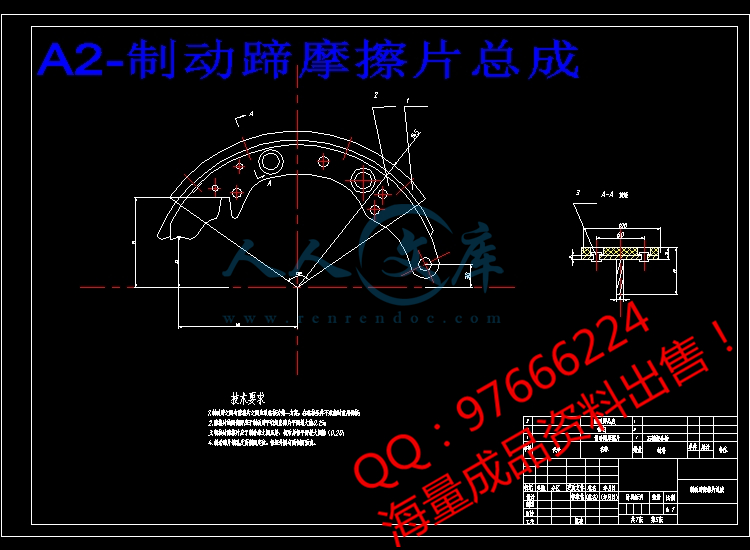

4.2制动蹄15

4.3制动底板15

4.4支承16

4.5制动轮缸16

4.6摩擦材料16

4.7制动器间隙的调整方法及相应机构16

4.8液压驱动机构的设计与计算17

4.9制动器的校核17

5 结论19

致 谢20

参考文献21

毕业设计(论文)知识产权声明22

毕业设计(论文)独创性声明23

附录124

附录225

川公网安备: 51019002004831号

川公网安备: 51019002004831号