摘 要

冰箱扣手是塑料成型制品,是以塑料为主要结构材料经成型加工获得的制品。塑料成型制品应用广泛,特别是在电子仪表、电器设备、通信工具、生活用品等方面获得大量应用。

塑料制件加工的主要方法是塑料成型加工。塑料成型的概念是将各种形态的塑料熔融塑化或加热达到要求的塑性状态,在一定压力下经过要求形状模具或填充到要求模具模腔内,冷却定型后,获得要求形状、尺寸及性能塑料制件的生产过程。

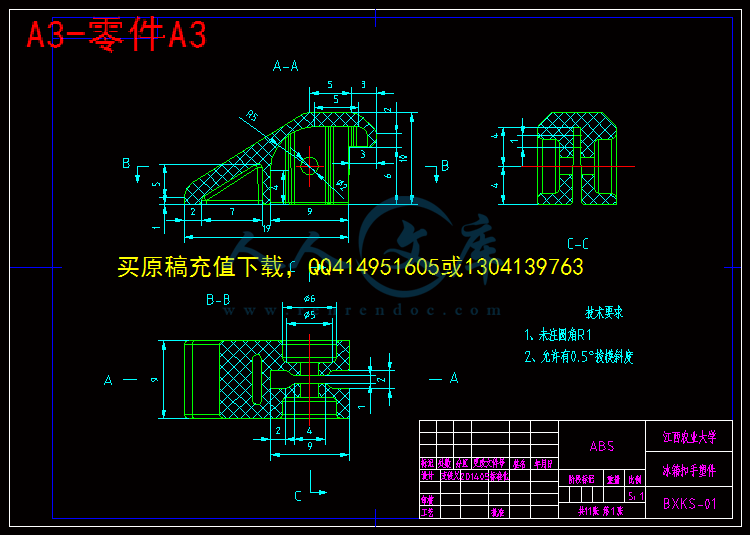

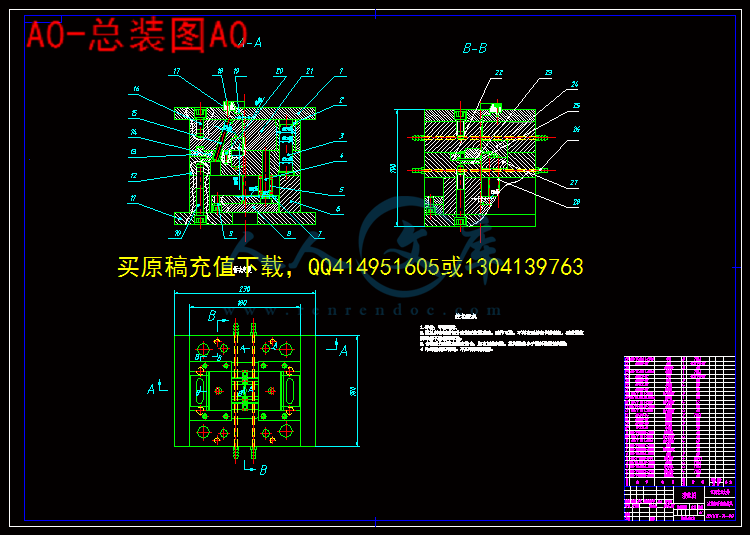

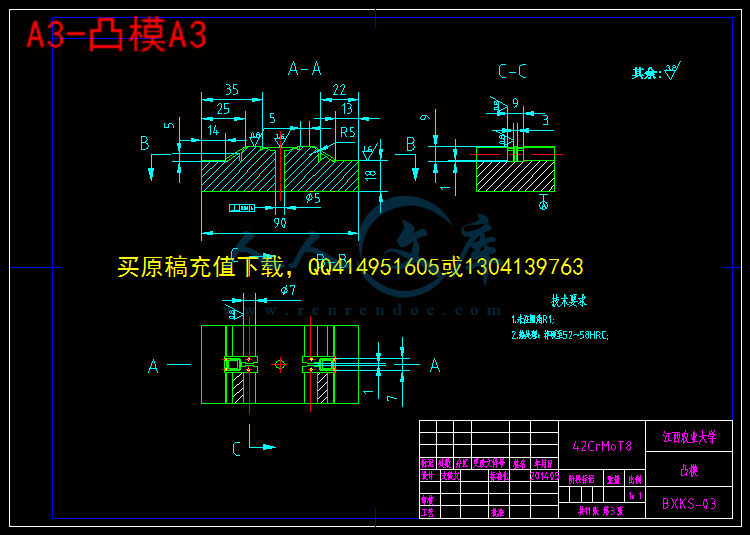

采用Pro/E对零件进行结构分析,进行塑料注塑模的设计计算,选择合适的注射机,设计模架,浇注系统等方面,为保证制件的顺利脱模,设计侧抽芯机构,绘制模具三维图。

关键词:塑料,注射模,注射机,Pro/E

Abstract:

The refrigerator hand-clasping is the plastic molding products,as the main structure material in plastic forming processing get products. The plastic molding products applied widely, especially in the electronic instrument, electrical equipment, and communication tools, supplies, etc acquire a large application.

The main processing plastic objects were method is plastic forming.The plastic molding is will some form of plastic raw material plastication melt or heating to meet requirements of plastic state, under some pressure after request shape of mold or filling requirements to mold a mold cavity, wait for after cooling to finalize the design, procurement requirements shape, size and performance of plastic parts production process.

The Pro/E to parts structure analysis, plastic injection mold design calculation, choose appropriate injection machine, design formwork, gating system, etc, to ensure that the product's smooth stripping, also designed the side core-pulling mechanism, and drawing three dimensional figure of the mould.

Key Words:Plastic, Plastic injection mold, Plastic injection,Pro/E

目 录

摘 要I

Abstract:I

1 塑件分析1

2 塑件的工艺分析2

3 注射机的选用与校核4

4 模具结构设计6

5 模具的整体设计17

总 结17

参考文献18

致 谢19

川公网安备: 51019002004831号

川公网安备: 51019002004831号