摘 要

关于模具发展趋势,我认为这主要取决于两个方面,即一方面是模具为之服务的各行各业的发展趋势,另一方面是整个社会和世界科学技术的发展趋势,这实际上就是需要和可能。模具是为制件,也就是成形产品服务的,因此模具必然要以制件(成形产品) 的发展趋势为自己的发展趋势,模具必须满足他们的要求。制件发展趋势主要是轻巧、精美、快速高效生产、低成本与高质量,每一项都预示了模具发展趋势。

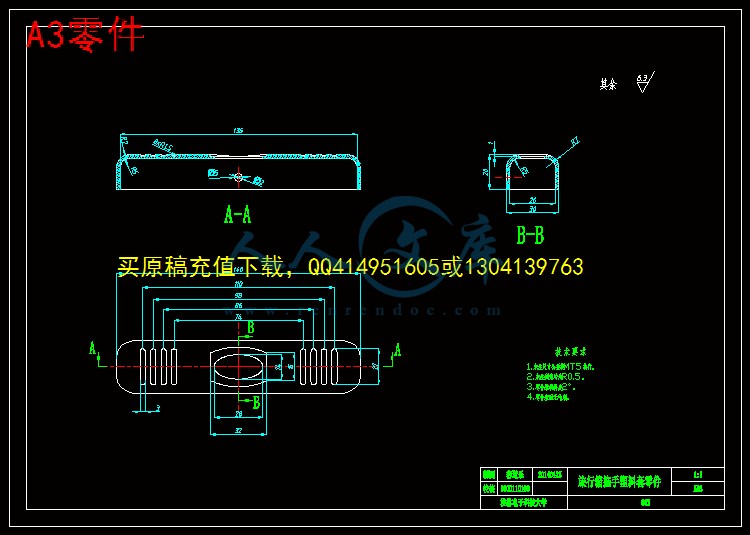

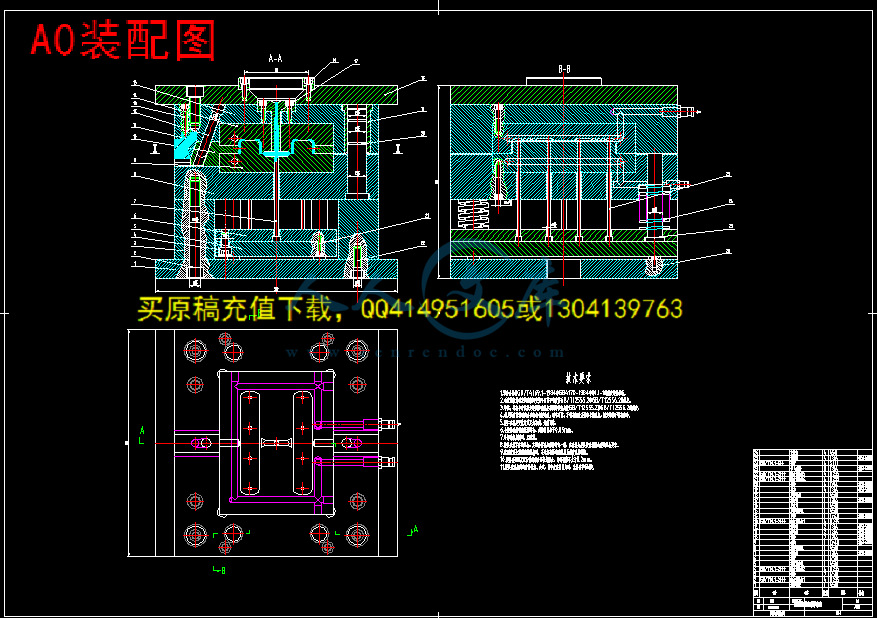

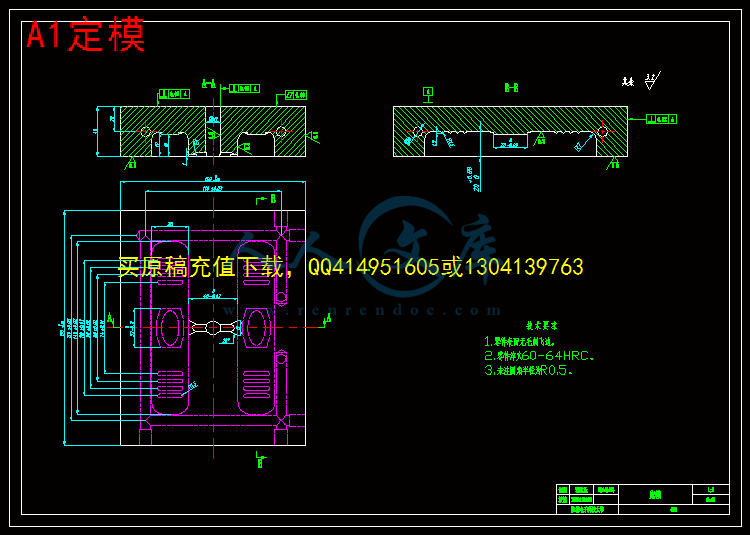

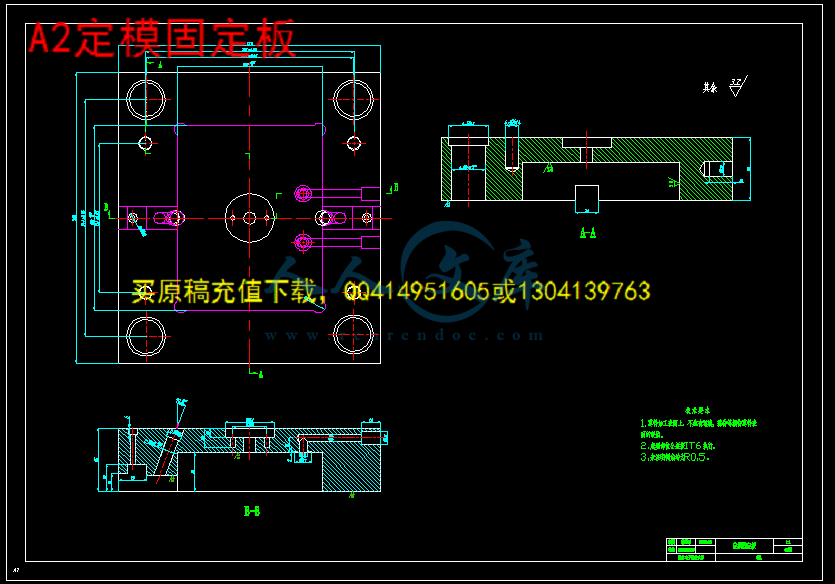

本文为旅行箱拖手塑料套的产品设计到整个注塑模的设计过程,即对长140mm、宽30mm、高20mm拖手塑料套的注塑模具设计。塑料套的外形设计有防滑纹理,在侧边设有固定的螺丝孔以便固定在伸缩支架上。其螺钉孔根据设计要求采用侧向抽芯机构进行抽芯,然后通过顶杆将制件顶出。稳重介绍了拖手塑料套的外形、结构等设计要求,制件的结构分析,制件的工艺性分析,制件质量、体积计算,材料、生产批量的确定,成型方法的选取及成型设备的选择,注塑模的结构设计,在设计模具时的相关计算,模具机构设计,注射机的选择及其校核,成型零件的相关计算及其校核。在设计中进行大量的计算,如成型零件工作尺寸的计算,型芯、型腔径向和高度计算,推杆直径及其数目的计算等。由此在整个设计计算的过程中,确定了模具的结构及相关的零部件。在整个模具的设计过程中采用CAD/CAM设计系统进行一体化设计,用PROE软件进行塑件的三维造型及其分析,用AUTOCAD进行二维的工程图二维设计。

关键词:注塑模;塑料;抽芯;型腔;型芯

Abstract

About mold development trend, I think it depends mainly on two aspects, that is, on the one hand is development trend of the mold service for all walks of life, on the other hand, the whole society and the world trend of the development of science and technology, it is actually need and possible. Molds for the parts, that is, forming products and services, so the mold must to stamping forming products () for their own development trend, the development trend of die must meet their requirements. Development trend of the main parts is light and elegant, fast and efficient production, low cost and high quality, each announced a mold development trend.

The thesis gives a detailed introduction the process of an injection mold’s design, which is from product design to the whole plastic injection mold. This is a design for a plastic injection mold whose length is 140mm, 20mm in width, 20mm in height. The form design for a plastic sleeve has skidproof textures. Its broadside has screw eyes . The function of the hole is used to fix plastic sleeve on the telescoping shoring column. According to the design, its screw eyes are required to use a side core-pulling mechanism to do side core-pulling. After that, the knockout pin pushes out a fabricated part. This paper introduces the design standards of a drag hand plastic’s form, structure, etc, the process analysis of a fabricated part’s quality, volume calculation,materials, the confirm of production lot, the choice of molding methods and the choice of mold equipment, the injection’s structural design, the relative calculation in designing a mold, a mold’s mechanism design, the choice and check of an injection machine, relative calculation and check about molded parts. Meanwhile, it explains the working processes. Plenty of calculations during the design are the calculation of working dimensions for molded parts, the calculations of core, cavity diameter and the mold’s height, the calculation of a push rod’s diameter and the number of push rods, etc. So, the mold’s structure and some relative components are confirmed during the process of the calculation in the whole design. CAD/CAM design system is applied to in the design process of the whole mold. At the same time, PROE software is used to form 3D mold and its analysis, AUTOCAD is used to export 2Dengineering drawing.

Keywords: Injection mold; plastic; pumping core; cavity;core

目 录

引 言1

1 塑件设计分析2

1.1 选题意义2

1.2 塑件模型建立2

1.3 塑件参数设计2

1.4 材料选择3

1.5 塑件的壁厚4

1.6 塑件的脱模斜度4

1.7 分型面设计5

1.8 确定型腔数量以及排列方式6

2 注塑设备和模架选择7

2.1 注塑设备选择7

2.2注塑机重要参数校核9

2.2.1型腔数量的确定和校核9

2.2.2 注塑容量校核9

2.2.3 锁模力校核10

2.2.4 注塑压力校核11

2.2.5 开模行程校核11

2.2.6 推出装置校核12

2.2.7 模具外形尺寸校核12

2.3 模架选择12

2.3.1模架类型选择的前提条件12

2.3.2模架系列的选择13

3 浇注系统设计14

3.1 主流道设计14

3.1.1 浇口套设计14

3.1.2 浇口套的固定形式15

3.2 分流道的设计16

3.2.1 分流道的形状及尺寸选择16

3.2.2 分流道的设计16

3.3 浇口设计17

3.3.1 侧浇口的尺寸18

3.4 冷料穴和钩料脱模装置18

3.5 排气系统的设计19

4 成型零件设计20

4.1 型腔模的设计20

4.2 型芯模的设计20

5 推出机构设计23

5.1 推杆推出机构23

5.2 推出机构的复位23

5.3 推出机构的布局24

6 侧向抽芯机构的设计25

6.1 抽芯距的计算25

6.2 抽芯力的计算25

6.3 斜导柱直径的确定26

6.4 斜导柱长度的计算26

6.5 楔紧块的设计27

7 冷却系统设计28

7.1 冷却管道的工艺计算29

7.1.1 冷却管道的直径计算29

7.2 冷却水道的结构设计29

8 导向机构的设计31

8.1 导向机构的设计要点31

8.2 导柱的设计与选择31

8.3 导套的设计与选择32

9 模具装配图32

9.1 模具装配图的绘制32

结 论33

谢 辞34

参考文献35

附 录36

引 言

关于模具发展趋势,我认为这主要取决于两个方面,即一方面是模具为之服务的各行各业的发展趋势,另一方面是整个社会和世界科学技术的发展趋势,这实际上就是需要和可能。模具是为制件,也就是成形产品服务的,因此模具必然要以制件(成形产品) 的发展趋势为自己的发展趋势,模具必须满足他们的要求。制件发展趋势主要是轻巧、精美、快速高效生产、低成本与高质量,每一项都预示了模具发展趋势。现简要分析下:要轻巧就会增加使用塑料及开发新材料,包括各种新型塑料、改性塑料、金属塑料、镁合金、复合材料等等,这就要求有新的成形工艺。要精美,就要求外形美观大方,内部无缺陷,这就要求有精细、精密和高质量模具与之相适应。目前我们在精细化方面差距很大,精细化往往被忽视,功亏一篑。快速高效生产,这一方面是要求模具企业要尽量缩短模具生产周期,尽快向模具用户交付模具,另一方面更重要的是要使用户能用你提供的模具来快速高效地生产制品。例如一模多腔多件生产、叠层模具、利用好热流道技术来缩短成形时间以及使用多层复合技术、模内装饰技术、高光无痕注塑技术、在线检测技术、多工序复合技术、多排多工位技术等等。同时制件成形过程智能化还要求有智能化的模具来适应。低成本,这既要通过模具生产的设计、加工、装配来实现模具的低成本制造和低成本供应,更重要的是要使模具用户能使用模具来实现低成本生产。这就对模具提出了更高的要求。模具生产企业必须做到先使模具用户赚钱,然后才能使自己赚钱。在要求低成本的过程中,无论是模具生产企业还是使用模具的企业,不断改善管理,逐步实现信息化管理都是企业的共同要求及进步和发展的方向。高质量,要做到制品的高质量,首先必须是模具的高质量,模具的稳定性一定要好,保证。制品的一致性也要好,而且还要保证寿命。高质量模具与技术休戚相关除上述各点外,许多新领域、新兴产业、新制件和个性化要求也都会对模具不断提出新要求。所以发展。趋势的本身也是在不断发展的从科技发展趋势来看模具发展趋势可以先从下列最基本的六个方面进行分析:

新材料→模具新材料及为成形产品新材料成形的新型模具

新工艺→新的成形工艺及模具加工的新工艺

新技术→技术进步带动模具生产逐步向超高速、超精和高度自动化方向发展

信息化→数字化生产、信息化管理、充分利用IT技术

网络化→溶入和利用好世界全球化网络

循环经济与绿色制造一用尽量少的资源来创造尽量多的价值,包括回收再利用与环保等,不但模具要能这样,而且更要使模具用户也能这样。

川公网安备: 51019002004831号

川公网安备: 51019002004831号