您若下载本次文件,将获得(CAD图纸+word文档)源文件哦!

以下为本次文件的目录及部分图纸截图

【需要其他机械类资料可以联系QQ97666224】

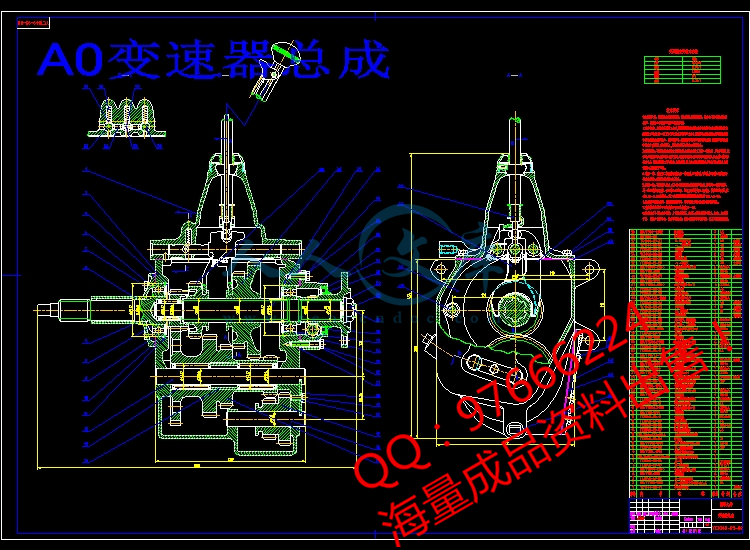

低速载重型汽车变速箱的设计与分析【20张图纸】【优秀】【带三维】【word说明书+CAD全套设计】

目 录

1 前言………………………………………………………………………3

2 低速载重汽车主要参数的确定…………………………………………4

2.1质量参数的确定………………………………………………………………………4

2.2发动机的选型…………………………………………………………………………4

2.3车速的确定……………………………………………………………………………5

3变速箱的设计方案………………………………………………………6

3.1设计方案的确定………………………………………………………………………6

3.1.1两轴式………………………………………………………………………………6

3.1.2三轴式………………………………………………………………………………6

3.1.3液力机械式…………………………………………………………………………6

3.1.4确定方案……………………………………………………………………………6

3.2零部件的结构分析……………………………………………………………………7

4 基本参数的确定……………………………………………………………………8

4.1变速箱的挡位数和传动比……………………………………………………………8

4.2中心距……………………………………………………………………………10

4.3变速箱的轴向尺寸………………………………………………………………11

4.4齿轮参数…………………………………………………………………………11

4.5各档齿轮齿数的分配……………………………………………………………14

5 齿轮的设计计算…………………………………………………………………16

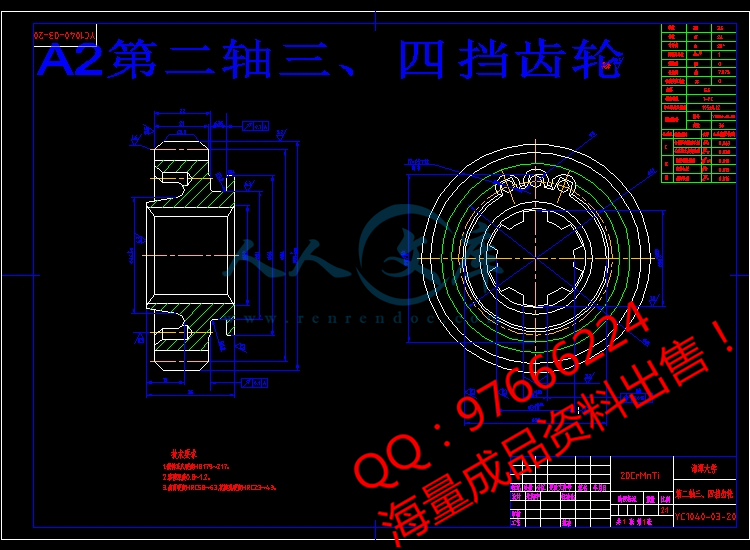

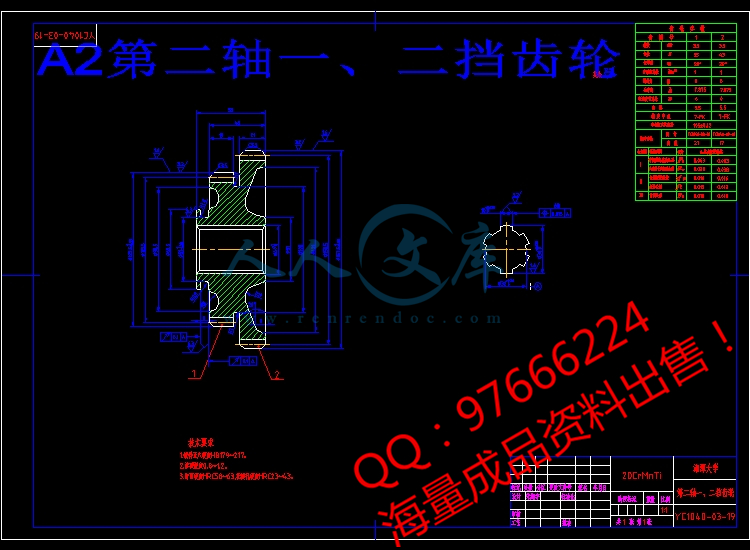

5.1几何尺寸计算……………………………………………………………………16

5.2齿轮的材料及热处理……………………………………………………………17

5.3齿轮的弯曲强度…………………………………………………………………17

5.4齿轮的接触强度…………………………………………………………………18

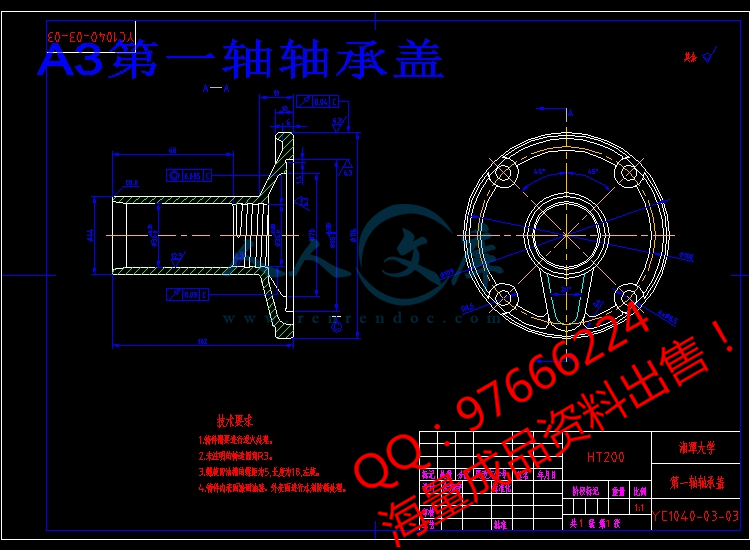

6轴的设计与轴承的选择…………………………………………………………21

6.1轴的设计…………………………………………………………………………21

6.2轴承的选择………………………………………………………………………34

7结论……………………………………………………………………………………41

参考文献………………………………………………………………………………42

致谢……………………………………………………………………………………43

附录一……………………………………………………………………………………44

附录二……………………………………………………………………………………48

低速载货汽车变速箱的设计与分析

摘 要:课题来源于生产实际,依据《机动车安全技术条件》和《汽车机械变速器总成技术条件》,针对低速载货汽车的运行特点而设计。参与了汽车的总体设计,确定了汽车的质量参数,选择了合适的发动机,并且计算出汽车的最高速度。

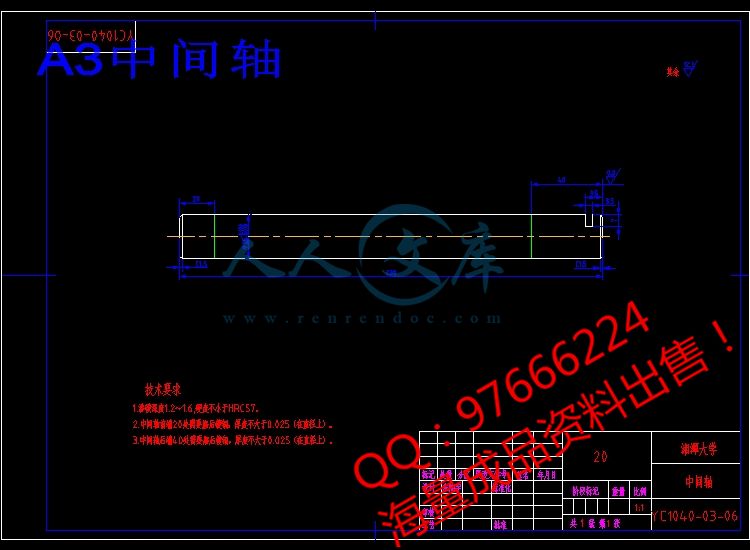

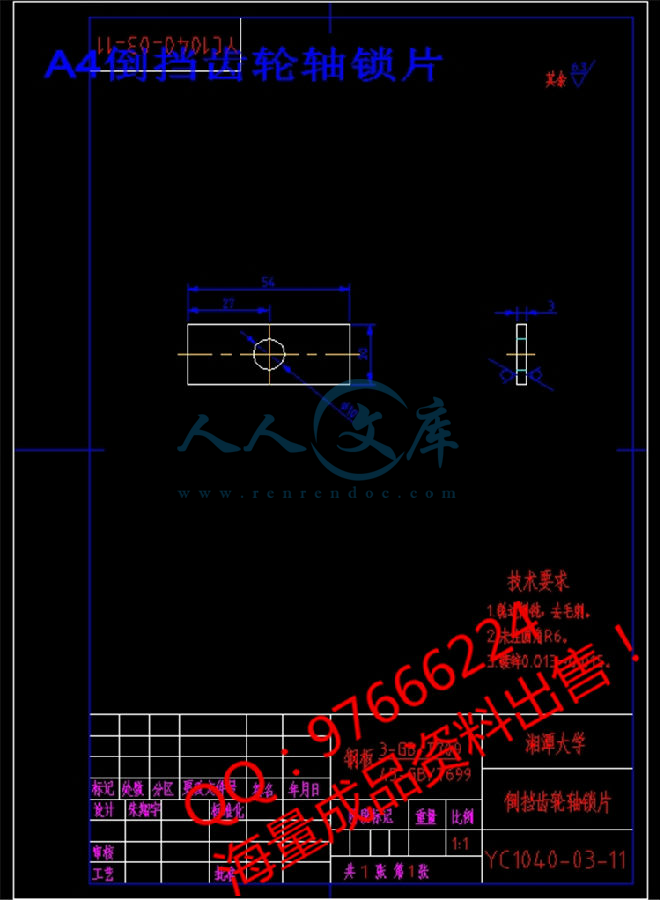

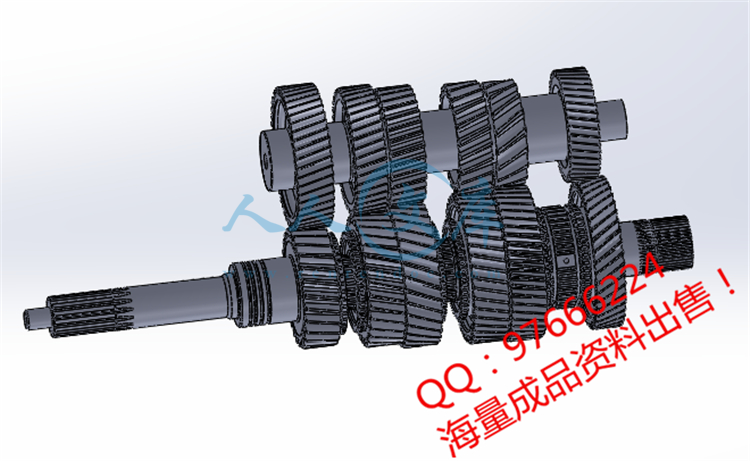

关于变速器的设计,首先选择标准的齿轮模数,在总挡位和一挡速比确定后,合理分配变速器各挡位的速比,接着计算出齿轮参数和中心距,并对齿轮进行强度验算,确定了齿轮的结构与尺寸,绘制出所有齿轮的零件图。根据经验公式初步计算出轴的尺寸,然后对每个档位下轴的刚度和强度进行验算,确定出轴的结构和尺寸,绘制出各根轴的零件图。根据结构布置和参考同类车型的相应轴承后,按国家标准选择合适的轴承,然后对轴承进行使用寿命的验算,最终完成了变速器的零件图和装配图的绘制。

此变速器的齿轮都为标准齿轮,档位数和传动比与发动机参数匹配,保证了汽车具有良好的动力性和经济性。该变速器具有操纵简单、方便、传动效率高、制造容易、成本低廉、维修方便的特点,适合低速载货汽车的使用。

关键词:低速载货汽车;变速器;设计

Design The Transmission of Low-speed Truck

Abstract: The topic comes from the production reality, which is based on the safety specifications for power driven vehicles operating on roads and the specifications for the automobile mechanical transmission. It designs the low-speed truck’s movement characteristic. The automobile quality parameters are determined, according to the automobile system design, choosing the appropriate engine, and calculating the maximum speed.

When design the transmission, first, we choose the standard gear modulus and determine all speed’s proportions after we choose the number of the transmission’s gears and the first gear, then calculate the gear’s parameter and the center distance, and the gear needs the intensity checking calculation. We determine gear’s structure, then complete drawing of the gears’ component. According to the empirical formula, we preliminary carry on the checking calculation to each gear’s rigidity and the intensity to determine the axis’ structure and size, and thus draw up various axis’ component drawing. After arranged structure and compared with the similar type of vehicle’s bearing, according to the national standard, we select the appropriate bearings, and then calculate the service life of the bearings. Finally drawing of the component and the assembly of the transmission are completed.

Because the transmission gear is the standard gear and the number of gears and speed’s proportions match to the engine conditions, which ensure the necessary power and economy. This transmission has many merits of simple operation, efficient, easy manufacturing, low cost, and convenient.

Key words: Low-speed Truck;Transmission;Design

川公网安备: 51019002004831号

川公网安备: 51019002004831号