您若下载本次文件,将获得(CAD图纸+word文档)源文件哦!

以下为本次文件的目录及部分图纸截图

【需要其他机械类资料可以联系QQ97666224】

摘 要

本课题是根据目前我国旋锻技术的发展现状而进行的数控旋锻机床的设计与研究。 由于现代科学的发展,对产品的质量提出了更高的要求。从而对机床的要求也就有的更加的要求 ,传统的加工工艺生产效率低,并且精度不能保证[1]。但是数控旋锻机采用了闭环系统,自动进行插补运算,改变了传统开环系统形式,通过电气与液压系统有效配合,大大提高了旋锻机的使用性能。现代机械制造中加工机械零件的方法很多:除切削加工外,还有铸造、锻造、焊接、冲压、挤压等,但凡属精度要求较高和表面粗糙度要求较细的零件,一般都需在机床上用切削的方法进行最终加工。机床的进步反映了一个国家的工业化进程水平。而特种数控旋锻机床作为具有先进制造技术的基础制造装备,已被广泛应用于航天、航空、能源、交通等各个领域,其加工精度、加工效率和加工能力的高低直接影响着一个国家国民经济和国防建设的发展。论文研究对象是一种德国进口并可进行旋转锻造加工的多功能特种数控机床,目前国内并无此种设备的研制和生产。本论文正是对此种机床的结构进行分析并进行主体机床结构的仿制、改进和设计。研究中应用先进设计手段辅助机床结构设计,利用SolidWork软件进行机床三维布局及造型设计,机床的设计效率和设计过程可视化程度都得到较大提高。论文研究除完成了数控旋锻机床结构的主体设计,论文中还运用有限元分析软件,对机床使用的模具进行动态受力分析。论文还对数控旋锻机床的模具和主要零部件的制造和修整做了较详细的介绍,对数控旋锻机床的检修和保养方法也做了说明。希望在借鉴和学习国外先进机床制造技术的情况下,能对国内特种机床的发展和进步提供一些资料和参考.

关键词:CNC;旋锻机;模具;有限元分析;solidwork;动力学分析

Abstract

The issue is the design and research of CNC rotary forging machine according to the current development status of swaging techniques carried out. Due to the development of modern science, the quality of the product a higher requirement. Thus some of the requirements of the machine will be more demands, low productivity of traditional processing technology, and accuracy can not be guaranteed. But CNC rotary forging machine uses a closed-loop system, automatic interpolation operation, changing the form of the traditional open-loop system, electrical and hydraulic systems through effective coordination, greatly improving the performance swaging machine. Mechanical machining methods of modern manufacturing many mechanical parts: Cutting addition, there are casting, forging, welding, stamping, extrusion, etc. Where the higher accuracy but the required surface roughness and fine parts, generally takes final processing methods on the cutting machine. Machine progress reflects the level of a country's industrialization process. The special CNC rotary forging machine as the basis for manufacturing equipment with advanced manufacturing technology, has been widely used in aerospace, aviation, energy, transportation, and its precision machining, processing efficiency and the ability to directly affect the level of a country's economy and the development of national defense construction. Thesis is a study of German imports and can be rotated forging special multifunctional CNC machine tools, there is no domestic development and production of such equipment. This paper is to analyze the structure of such a machine and copy machine body structure, improvement and design. Research in the application of advanced design tools assist machine design, the use of software tools SolidWork dimensional layout and design, machine design efficiency and process visualization have been greatly improved. In addition to the completion of the main thesis of CNC swaging machine structure design, the paper also uses finite element analysis software tools used to mold the dynamic mechanical analysis. The paper also manufacture and repair of CNC machine tools swaging dies and major components to do a more detailed introduction to CNC swaging machine repair and maintenance methods also made instructions. In the case of hope to learn from foreign advanced machine manufacturing technology, capable of national progress and development of special tools provide some information and reference

Keywords: CNC; rotary forging machine; die; finite element analysis; solidwork; kinetic analysis

目录

摘 要I

AbstractII

1绪论1

1.1概述1

1.2 数控旋锻机床的产生与发展1

1.2.1 数控旋锻机床的产生1

1.2.2数控旋锻机床的发展1

1.3数控旋锻机床的使用领域2

1.3.1 数控旋锻机床在个领域的应用2

1.3.2数控旋锻机床主要使用领域2

1.3.3 数控旋锻机加工炮管、枪管等产品3

1.3.4 异形管材4

1.4国外数控锻造技术的发展现状与发展趋势4

1.4.1锻造技术的发展现状4

1.4.2发展趋势5

1.5课题研究意义与目的5

1.5.1本课题研究的意义5

1.5.2本课题研究的目的6

1.6本课题研究的主要内容6

2数控旋锻机床的工作原理与方案论证7

2.1 旋锻机机床工作原理7

2.2 旋锻机结构形式与方案论证8

2.2.1旋锻机结构形式8

2.2.2旋锻机的结构方案论证9

3数控旋锻机床性能和要求11

3.1 数控旋锻机床性能11

3.1.1 数控旋锻机床的加工特点11

3.1.2 旋锻锻造机床加工的优点11

3.1.3数控旋锻机床的缺点12

3.1.4数控旋锻机床加工出零部件的精度12

3.2 旋锻加工与传统加工方式的比较13

3.2.1 零部件传统的加工方式13

3.2.2 数控旋锻机床的加工相对传统机械加工的优势13

3.3 旋锻加工时对毛坯件的要求14

3.3.1对毛坯尺寸误差的要求14

3.3.2 表面光洁度度及形状误差的要求14

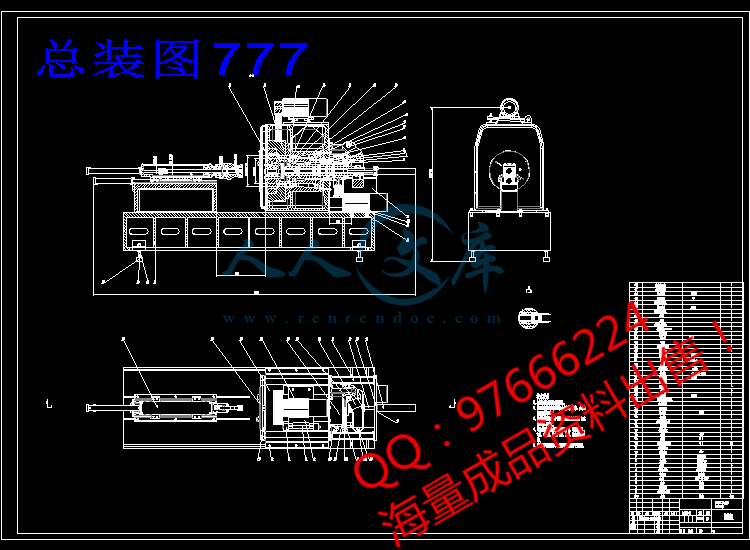

4数控旋锻机床主要组成部分15

4.1 数控旋锻机床主要组成部分15

4.2 数控旋锻机床的楔铁进给机构15

4.3 数控旋锻机床锁紧机构17

4.4 数控旋锻机床冷却油供应系统18

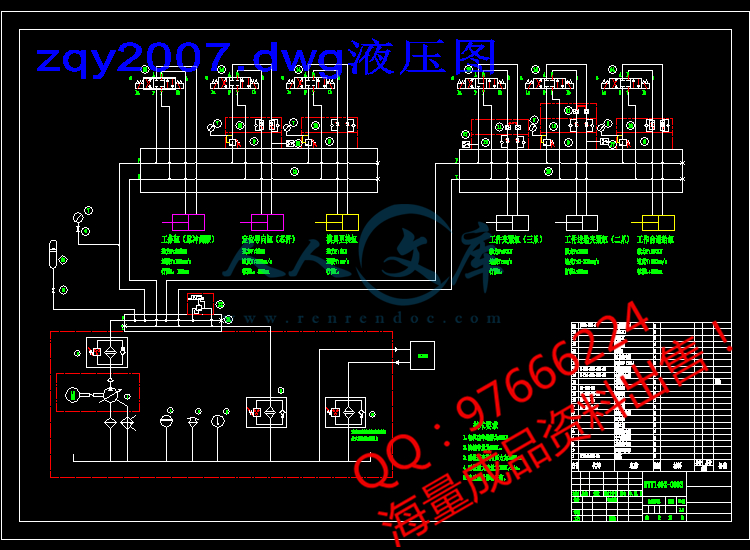

4.5数控旋锻应系统机床液压油供18

4.6数控旋锻机床控制系统19

4.7数控旋锻轴咬合方式19

4.8数控旋锻机床的电力驱动以及电机座19

4.9刹铁和模具的设计20

4.10 模具的结构设计与分析21

5数控旋锻机床结构设计与校核22

5.2外轴与内轴支承部件的选择------轴承24

5.3旋锻机销轴强度校核24

5.4受倾覆力矩的螺栓组连接29

5.5普通V带传动设计30

5.6数控旋锻机离心力计算32

6有限元分析32

6.1结构有限元分析原理32

6.2结构有限元建模分析流程33

6.3支撑零部件有限元结构分析结果34

致 谢37

参 考 文 献38

川公网安备: 51019002004831号

川公网安备: 51019002004831号