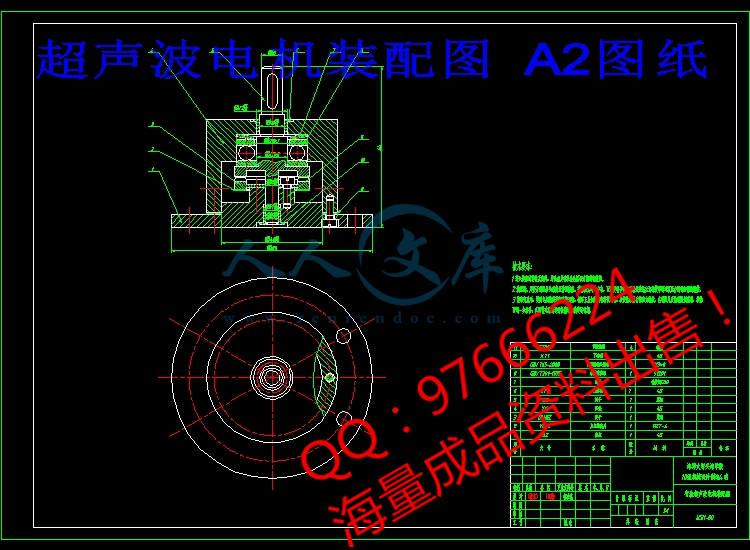

超声波电机的设计【7张图纸】【优秀】【word说明书+CAD全套设计】

收藏

资源目录

压缩包内文档预览:

编号:444620

类型:共享资源

大小:4.46MB

格式:ZIP

上传时间:2015-06-28

上传人:小***

认证信息

个人认证

林**(实名认证)

福建

IP属地:福建

45

积分

- 关 键 词:

-

x0115

超声波

电机

机电

设计

- 资源描述:

-

您若下载本次文件,将获得(CAD图纸+word文档)源文件哦!

以下为本次文件的目录及部分图纸截图

【需要其他机械类资料可以联系QQ97666224】

目录

第1章 绪论3

1.1 超声波电机的定义与发展历史3

1.2 超声波电机的基本工作原理5

1.3 超声波电机的分类6

1.4 超声波电机的特点和应用6

1.5 超声波电机技术的展望7

第2章超声波电机的运动机理8

2.1 椭圆运动的分析8

2.2 驻波的产生及行波的合成10

第3章 超声波电机的理论计算与设计13

3.1 定子谐振频率的计算13

3.2 压电陶瓷换能器的设计和制作16

3.2.1 压电陶瓷的设计16

3.2.2 压电陶瓷材料的选用17

3.2.3 压电陶瓷的接线方式17

3.3 定子的设计及制作19

3.3.1 定子尺寸与行波超声波电机输出特性的关系19

3.3.2 定子的内外径尺寸的选择21

3.3.3 定子的振动模态的选择21

3.3.4 定子的齿形齿数设计21

3.3.5 定子的结构设计22

3.3.7定子材料的选择23

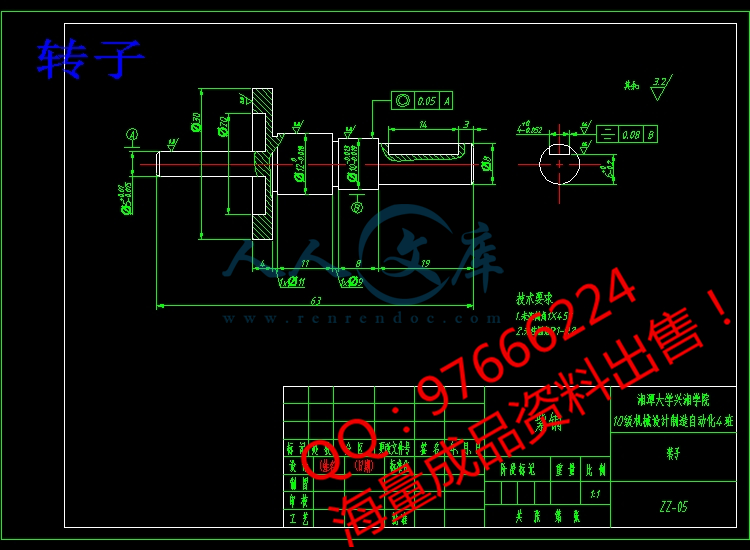

3.4 转子的设计及制作24

3.4.1 超声波电机转子的柔性要求24

3.4.2 定转子径向弯曲配合25

3.4. 摩擦层的设计26

3.5 定转子设计的总结26

第4章 超声波电机的驱动控制技术27

第5章 超声波电机整体结构设计30

第6章 全文总结32

参考文献33

致谢34

附录 英文翻译译文35

超声波电机的设计

摘要:超声波电机是一种利用压电陶瓷的逆压电效应工作的新概念、新原理电机。与传统电磁型电机截然不同,其驱动力矩并非由电磁感应产生,它利用压电陶瓷的压电效应使定子产生超声波振动,通过定子和转子间的摩擦力来驱动转子。由于超声波电机特殊的工作原理,它具有很多传统电磁电机无法比拟的优越性能,如结构紧凑、低速大转矩、响应速度快、不受磁场影响、断电自锁、可直接驱动负载等。正是由于超声波电机具有许多的优点和广阔的应用前景,成为当前世界范围内的一门新兴前沿课题。

本文主要以超声波电机为研究对象,设计超声波电机的实验样机。研究的主要内容可概括如下:系统地总结国内外超声波电机的发展历史和重要意义,介绍了超声波电机的工作原理、分类、特点及其应用前景。在对超声波电机相关理论研究的基础上,从超声波电机定子设计着手,详细介绍了超声波电机的设计过程。

关键词:超声波电机 压电陶瓷

- 内容简介:

-

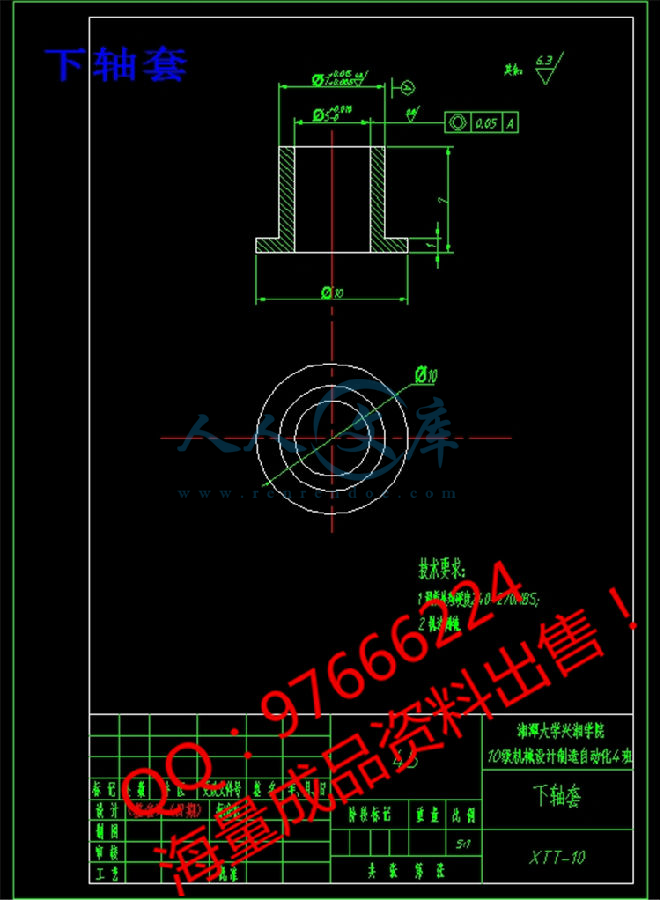

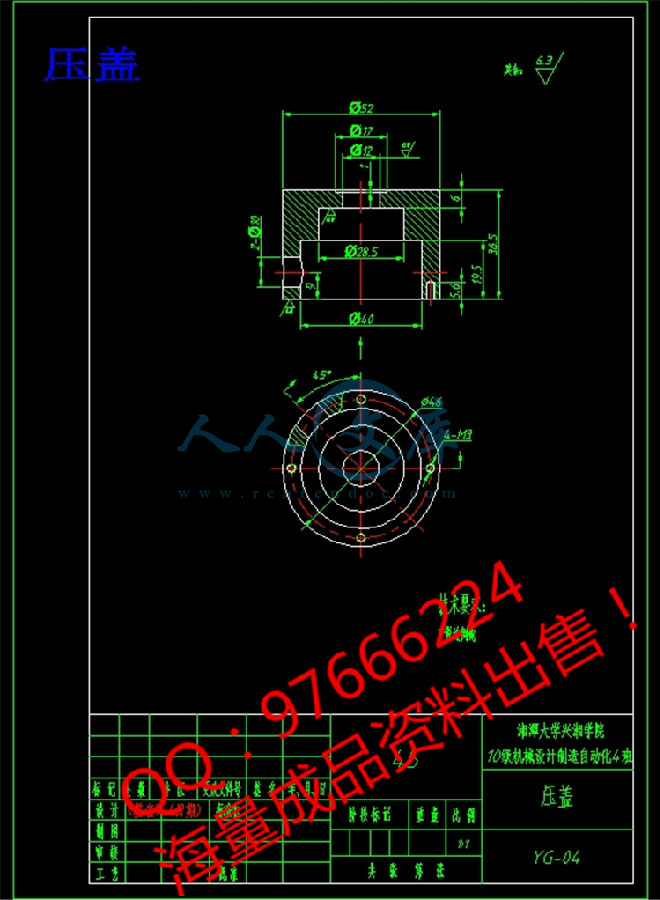

湘潭大学兴湘学院毕业论文(设计)任务书论文(设计)题目:超声波电机的设计 学号:2010963101 姓名:罗悠 专业:机械设计制造及其自动化 指导教师: 周里群 系主任: 刘伯希 一、主要内容及基本要求超声波电机是国内外日益受到重视的一种新型驱动电机,通过查找相关文献,熟悉其工作原理和运行机理,结合本科所学机械各学科方面的知识,完成超声波电机结构部分的设计。主要研究内容包括以下几个方面:1超声波电机的运行机理。2定子谐振频率的计算。3压电陶瓷换能器的设计和制作。4定子的设计及制作。5转子的设计及制作。6编写设计说明书:设计说明书按设计程序编写。 基本要求:学习查阅文献,具备综合归纳资料的能力;综合运用本科阶段所学知识,分析与解决超声波电机结构设计过程中所遇问题;并利用AutoCAD软件绘制了其装配图和各个零件图;通过翻译3000字的外文资料获取国外在该行业的最新发展动态。 二、重点研究的问题理解超声波电机的工作原理和运行机理,弄清其结构特点,定子谐振频率的计算,定子的设计及制作,转子的设计及制作;理解超声波压电陶瓷和压电振子的特性,弄清超声波电机的振动特性及动力响应特性;理解超声波电机的驱动和控制及超声波电机的分析与设计。设计一台超声波电机。 三、进度安排序号各阶段完成的内容完成时间1选题第1周2查阅与收集资料第25周3超声波电机结构的设计第69周4完成所要求图纸第1011周5完成设计说明书第1213周6进行最后的修改第14周7答辩第15周四、应收集的资料及主要参考文献1 刘晋春,特种加工,第五版M.机械工业出版社.2008 2 史敬灼,超声波电机运动控制理论与技术.北京:科学出版社.2011.10 3 胡敏强,金龙,顾菊平,超声波电机原理与设计. 北京: 科学出版社.2005 4 姜楠,方光荣,刘俊标,束娜. 国内外超声波电动机驱动技术的最新进展. 微特电机. 2005.9 5 赵淳生,对发展我国超声电机技术的若干建议.微电机.2006 6 胡敏强,超声电动机的研究及其应用J.微特电机.2000 7 淮良贵,纪名刚,机械设计,第六版M.北京:高等教育出版社,1996 8 郑凯,杨义勇,胡仁喜.Solid Edge应用教程M.清华大学出版社,2008.4 9 芦亚萍,孟繁琴,袁云龙.超声波电机研究现状.微电机.2005 10 杨明,阙沛文. 超声电机变频驱动源的设计与分析. 压电与声光。 11顾绳谷,电机及拖动基础,第四版M. 机械工业出版社.2007.10 12罗宗泽,罗圣国.机械设计课程设计手册M.高等教育出版社,2006.5 湘潭大学兴湘学院毕业设计说明书题 目: 超声波电机的设计 专 业: 机械设计制造及其自动 学 号: 2010963101 姓 名: 罗悠 指导教师: 周里群 完成日期: 20140520 Failure analysis of a vibrating shaft in a fretting wear simulatorYoung-Ho Lee*, Jae-Yong Kim, Hyung-Kyu KimKorea Atomic Energy Research Institute, 150 Dukjin-dong, Yuseong-gu, Daejeon 305-353, Republic of Koreaa r t i c l ei n f oArticle history:Received 11 July 2008Accepted 1 August 2008Available online 15 August 2008Keywords:Failure analysisFretting wear simulatorVibrating shaftHigh temperature and high pressure waterFracture surfacea b s t r a c tRecently, a fretting wear simulator was developed in order to evaluate the fretting wearbehavior of nuclear components in high temperature and high pressure (HTHP) water con-ditions. After 500 h tests, however, two vibrating shafts among four were fractured, whichwere connected to a specimen holder jig by using a bolt. The fracture surface was examinedusing both an optical microscope (OM) and a scanning electron microscope (SEM) to deter-mine the failure initiation and failure mode. It was found that the failure had initiated at acontact region between the vibrating shaft and the fuel rod holder jig and a fatigue crackwas propagated although it was difficult to prove it conclusively due to the heavily oxi-dized fracture surface. Near the failure locations, however, the thread hole was subjectedto a repeated loading due to the fact that the specimen holder jig had a circular motionfor simulating a vibration motion. This suggests that the vibrating shaft failure resultedfrom corrosion fatigue phenomenon because the fretting test had been performed at hightemperature (?320 ?C) and pressurized distilled water (?15 MPa) conditions. In this paper,the reasons for this failure and the fracture mechanisms are revealed and discussed byusing the OM and SEM results of the failure surface and the stress analysis of the contactregions between the vibrating shaft and the specimen holder jig. Finally, the above resultswere applied to a design change of the vibrating shaft.? 2008 Elsevier Ltd. All rights reserved.1. IntroductionThe failure phenomena of mechanical structures by material degradations in extreme environments have been reportedfrequently in various industries. One of these examples, is in nuclear power plants (NPPs). Generally, NPPs operate in a hightemperature (?320 ?C), pressurized water (?15 MPa) and radioactive environment. This condition inevitably results inmaterial degradations such as a corrosion, fatigue, irradiation embrittlement, creep, etc. during their operation. Anothersevere condition for degrading structural materials is known as a flow-induced vibration (FIV) of relatively slender structuresdue to the rapid flow velocity of primary and secondary coolants, which results in fretting damages between these slenderstructures and their supporting structures. These kinds of fretting damages have been experienced in the major componentsof NPPs such as the nuclear fuel rods, steam generator (SG) tubes and control rods 1. Among these components, in ourlaboratory, the fretting wear phenomenon of nuclear fuel rods has been investigated in order to examine and develop a fret-ting wear mechanism and a defect-free fuel assembly (FA), respectively. Generally, a FA consists of 16 ? 16 or 17 ? 17nuclear fuel rods, which have the following dimensions; 9.5 mm outer diameter, 0.6 mm wall thickness and about a 4 mlength. Because of the FIV phenomenon by a primary coolant, these slender fuel rods could easily vibrate, thus they aresupported by several spacer grid structures as shown in Fig. 1. Each cell of a spacer grid structure consists of two springsand four dimples. Therefore, a nuclear fuel rod is supported by a certain amount of spring force, which depends on the springshape and its stiffness. Under a high temperature in an operating NPP condition, however, the contact force between the fuel1350-6307/$ - see front matter ? 2008 Elsevier Ltd. All rights reserved.doi:10.1016/j.engfailanal.2008.08.013* Corresponding author. Tel.: +82 42 68 8761; fax: +82 42 863 0565.E-mail address: leeyhkaeri.re.kr (Y.-H. Lee).Engineering Failure Analysis 16 (2009) 12381244Contents lists available at ScienceDirectEngineering Failure Analysisjournal homepage: /locate/engfailanalrod and spring/dimple is gradually decreased due to a spring relaxation. In addition, the spring stiffness is also graduallyincreased because of an irradiation embrittlement of a spacer grid spring/dimple. Even though a certain amount of springforce is exerted on the fuel rod at its initial operation, a relatively small slip amplitude on the contact surface is unavoidableunder a severe FIV condition. Consequently, the contact force is gradually decreased and finally, a gap is opened up. Thismeans that the fretting wear mode could be changed from a sliding wear to an impacting wear with increasing operatingtime. Another important point is that the vibration characteristics of a nuclear fuel rod also changed due to a contactcondition change of a fuel rod. Therefore, it is quite difficult to examine the fretting wear mechanism of a nuclear fuelrod in NPP operating conditions.A vertical type of a fretting wear tester (FRETONUS, FRTtting Tester Of NUclear Systems) for a HTHP water condition wasdeveloped in order to evaluate the fretting wear behavior of nuclear components 2. After 500 h tests, however, two vibrat-ing shafts among four were fractured, which were connected to a specimen holder jig by using a bolt as shown in Fig. 2. It isFig. 2. Schematic views of the assembling method between the vibrating shaft and rod specimen holder jig and the fractured vibrating shaft after 500 htests at high temperature and pressurized water condition.Fig. 1. The schematic view of a nuclear fuel assembly that consists of 16 ? 16 or 17 ? 17 fuel rods and several spacer grid assembly.Y.-H. Lee et al./Engineering Failure Analysis 16 (2009) 123812441239essential to evaluate the reason for their failure and to improve the vibrating shaft design to confirm the reliability of thefretting wear tester for a long experiment. In this study, the reasons for the failure and the fracture mechanisms are revealedand discussed by using the OM and SEM results of the fracture surface, measurement of the micro-vickers hardness and thestress analysis of the vibrating shaft. Finally, the above results were applied to a design change of the vibrating shaft.2. Fracture surface analysis2.1. OM observationThe vibrating shaft is made of a conventional high-carbon martensitic stainless steel (SUS 440C) and this material iswidely used as tools or blades for use in relatively corrosive atmospheres 3. The chemical composition and mechanicalproperties are listed in Table. 1. Fig. 3 shows the OM result of the fracture surface for the vibrating shaft. Due to the HTHPwater condition, the fracture surface was heavily oxidized and it was difficult to obtain metallographic proof by using theOM observation. However, it is expected that the failure was initiated at a contact region between the vibrating shaft andthe fuel rod holder jig because these two parts was assembled by using a bolt as shown in Fig. 2. During the fretting weartests, four vibrating shafts were reciprocated in their axial direction with a range of 200lm, a frequency of 30 ?Hz and asinusoidal motion by two electro-magnetic actuators that were arrayed at an angle of 90o. To generate a circular motionof the fuel rod specimen which is regarded as a conservative simulation of an actual fuel rod vibration in operating NPPs,the phase difference of the sinusoidal waveform for the shake signals of two actuators is set to 90oas shown in Fig. 4. Whenthe fuel rod specimen is vibrated with a circular motion, the contact region of the vibrating shafts with the fuel rod holder jigis expected to experience fatigue loads. Generally, striation traces that are distinct proof for a fatigue failure could be foundeasily on a fracture surface, if the structural materials are fractured under the fatigue loading conditions. However, the oxi-dized fracture surface of the vibrating shaft was examined by using SEM without any cleanings because the striation tracescould be expected to remove by the oxide removal process (i.e. acid cleaning).2.2. Hardness variationBefore the SEM observation, it is necessary to examine the mechanical property changes of the vibrating shaft, because itwas exposed to the HTHP water condition during 500 h tests. So, a micro-vickers hardness of the fractured vibrating shaftwas measured and its result is shown in Fig. 5. It is apparent that the micro-vickers hardness value increased accordingto the exposed temperature for the vibrating shaft. This result corresponds well with the tempering temperature effectTable 1Chemical compositions and mechanical properties (room temperature) of a conventional high-carbon martensitic stainless steel (SUS 440C) 4CMnSiPSCrMoFeChemical compositions (wt%)1.01.01.00.040.03170.75Bal.Yield strengthTensile strengthElongationElastic modulusDensityPoissons ratioMechanical properties1280 MPa1750 MPa4%200 GPa7.8 g/cm30.3Fig. 3. OM result of the fracture surface for the vibrating shaft: arrows indicate the expected crack initiation region.1240Y.-H. Lee et al./Engineering Failure Analysis 16 (2009) 12381244on the mechanical properties of SUS 440C 4. In this study, the higher carbon martensitic stainless steel is likely to retain alarge amount of untransformed austenite. It is thought that a delayed transformation may occur as temperature fluctuationsin several fretting wear tests because the 500 h tests at about 320 ?C did not have a negligible effect on the stress relieving ofthe vibrating shaft material. In addition, it is possible that some loss in ductility may result from a hydrogen embrittlementthat is an important concern in martensitic stainless steels in a heat-treating atmosphere containing hydrogen in the form ofdistilled water.2.3. SEM resultsFig. 6 shows the morphology of the fracture surface by using SEM. It is apparent that the fracture surface was almost cov-ered with oxides and it is difficult to detect evidence of a fatigue failure such as striation traces. From a careful inspection ofthe results, however, weak striation traces appeared near a lateral outer surface. Also, a crack propagation trace was found atthe contact region between the vibrating shaft and the fuel rod holder jig even though its characteristic could not be defineddue to the severe oxidation in the HTHP water condition. One of the interesting results is that an impacting wear scarappeared in the fracture surface of the vibrating shaft. This result means that the impacting wear between the two fracturedsurfaces is generated after a fracture because the fractured vibrating shaft is continuously reciprocated by an electro-mag-netic actuator regardless of the shaft failure. So, it is expected that the fatigue striation traces had disappeared and were cov-ered by the impacting wear motion and by the wear debris with a severe oxidation, respectively. Consequently, the vibratingshaft failure is expected to be initiated by a contact fatigue at the contact region and then the contact force exerted by a boltFig. 4. Actuating mechanism of the fuel rod by using two electro-magnetic actuators in FRETONUS: note that the fuel rod motions are changeable byadjusting vibration amplitudes and phase difference between two actuators.Fig. 5. Measurement result of the micro-vickers hardness according to the exposed temperature for the vibrating shaft.Y.-H. Lee et al./Engineering Failure Analysis 16 (2009) 123812441241screw will be decreased gradually. At this time, the initial crack propagation is gradually retarded and the contact conditionbetween the vibrating shaft and the fuel rod holder jig will be changed as shown in Fig. 7. So, it is necessary to examine thenew crack initiation region by using a stress analysis, which could verify the maximum stress region of the vibrating shaftduring a circular motion.3. Stress analysisIn order to analyze the stress distribution that the vibrating shaft experienced during the initiation of the new crack, theFE model with 10 mm in diameter and 233.5 mm in length was created by using the commercial 3D modeler, SolidEdge V.19as shown in Fig. 8. The displacement of the constrained cylinder at the left side is 0.2 mm and the connected region with theelectro-magnetic actuator at the right side is fixed. The 4 node linear tetrahedron elements were used for the vibrating shaft.Fig. 6. SEM micrograph of the fractured vibrating shaft surface.1242Y.-H. Lee et al./Engineering Failure Analysis 16 (2009) 12381244The FE model consisted of about 10,100 nodes and 47,200 elements. The used elastic modulus, yield strength, density andPoissons ratio of the commercial SUS 440C are listed in Table. 1. The commercial code, ABAQUS Standard ver. 6.63 5, wasused to post-process the model in order to calculate the Von-Mises stress of the vibrating shaft. The Von-Mises stress dis-Fig. 7. Variation of contact condition between the vibrating shaft and the fuel rod holder jig after the retardation of initial crack propagation.Fig. 8. FE model of the vibrating shaft generated by using a commercial 3D modeler.Fig. 9. Model of Von-Mises stress distribution in the vibrating shaft.Y.-H. Lee et al./Engineering Failure Analysis 16 (2009) 123812441243tribution in the vibrating shaft showed that the high stress concentrations were present at the edge of the thread hole andthe lateral outer surfaces as shown in Fig. 9. In particular, the lateral face experienced stresses in the magnitude of approx-imately 640 MPa. This value is about half of the yield stress of the vibrating shaft. It is considered that these high stress con-centrations are affected by the conservative boundary condition of the FE analysis. Consequently, the positions of the stressconcentration are in good accord with the crack generation traces revealed in the SEM observation. Based on this result, thedesign of the vibrating shaft was modified to reduce the stress concentration between the contact surfaces and the threadhole size of it was decreased to increase the fatigue life cycle.4. SummaryThe reason for the failure of the vibrating shaft in the fretting wear simulator was investigated by using a measurement ofthe micro-vickers hardness, OM & SEM observations and a finite element analysis. Due to the heavily oxidized fracture sur-face and the impacting wear between the two fracture surfaces after a failure, it is difficult to obtain the metallographic proofby using

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号