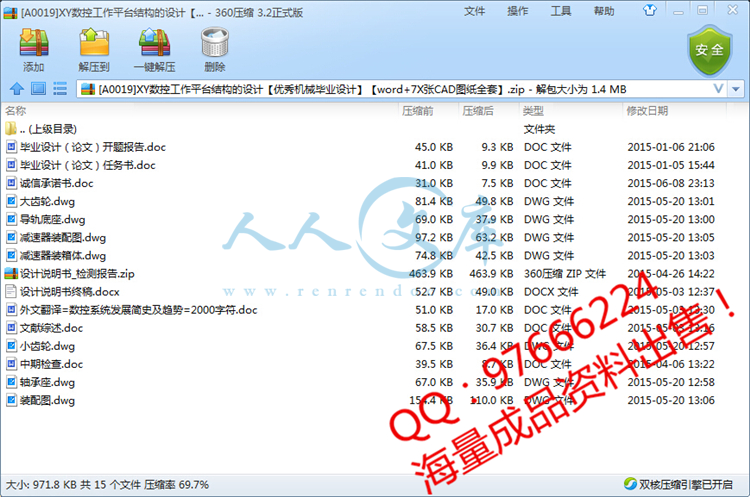

您若下载本次文件,将获得(CAD图纸+word文档)源文件哦!

以下为本次文件的目录及部分图纸截图

【需要其他机械类资料可以联系QQ97666224】

!【详情如下】CAD图纸+设计说明书.doc[10000字,16页]【需要咨询购买全套设计请加QQ97666224】.bat

减速器装箱体.dwg

减速器装配图.dwg

大齿轮.dwg

轴承座.dwg

导轨底座.dwg

小齿轮.dwg

装配图.dwg

文献综述.doc

毕业设计任务书.doc

毕业设计开题报告.doc

设计说明书_检测报告.zip

设计说明书终稿.docx

诚信承诺书.doc

中期检查.doc

外文翻译=数控系统发展简史及趋势=2000字符.doc

X-Y数控工作平台结构的设计

摘 要

本次设计的目的是使机床工作台来实现数字控制;相比普通的机床数控机床具有许多优点;可以处理更复杂的部件,精度高,有弹性,生产效率高,使用更方便等特点。并利用电脑控制,有效地消除人为误差,使零件,质量稳定可靠。自动化机器的出现明显的降低了操作人的劳动强度。

工作台是机器的重要组成部分,自动化工作台可大大降低劳动强度,提高劳动生产率,降低成本。数控X-Y工作台是数控技术,它充分利用了计算机硬件和软件的功能,从而实现机器控制,扩大加工机床的范围等最简单的应用;进一步增强了可靠性和精度。自改革开放以来,机械行业得到了充分的发展,但也有很多老机器在发展的过程中被淘汰,这些设备的改造仍然可以在生产中发挥了重要的作用,不仅提高精度和效率,并能有效地适应市场经济的需要。

关键词:数控; 工作台; 机床; 自动化

ABSTRACT

The purpose of this design is to make the machine table to achieve digital control; CNC machine tools compared to normal hard has many advantages; can process more complex parts, high precision, flexible, high production efficiency, easier to use and so on. And the use of computer control, effectively eliminating human error, so that the processing consistency of parts, stable and reliable quality. Automated machine high labor intensity of workers significantly reduced.

Workbench is an important part of the machine, automated workbench can greatly reduce labor intensity and improve labor productivity and reduce costs. CNC XY table is the simplest application of numerical control technology, which fully utilizes the capabilities of computer hardware and software in order to achieve the machine control, expanding the scope of the processing machine; further improved accuracy and reliability. Since the reform and opening up, the machinery industry has been fully developed, but there are a lot of old machines to be eliminated in the process of development, after the transformation of these devices can still play an important role in the production, not only to improve the precision and efficiency, And can effectively meet the needs of the market economy.

Key world: NC; Workbench; Machine tool; Automation

目 录

1 绪论1

1.1 X-Y 工作台的发展趋势及产业化的现状1

1.2数控X-Y工作台设计的意义和目的1

1.3本设计的主要内容和任务2

2 总体方案的设计2

2.1设计参数的确定2

2.2总体方案确定3

2.2.1机械传动部分的计算的选用与选型3

2.2.2控制系统的设计3

3 机械部分的设计3

3.1 导轨上移动部件的重量估算3

3.2 铣削力的计算4

3.3 直线滚动导轨副的计算与选型4

3.3.1 滑块承受工作载荷的计算及导轨型号的选取4

3.3.2 距离额定寿命的计算4

3.4滚珠丝杠螺母副的计算与选型5

3.4.1 最大工作载荷Fm的计算5

3.4.2 最大动载荷FQ的计算5

3.4.3 初选型号5

3.4.4 传动效率η的计算5

3.4.5 刚度的验算6

3.4.6 压杆稳定性校核6

3.5 步进电动机减速箱的选用6

3.6 步进电动机的计算与选型7

3.6.1 计算加在步进电动机转轴上的总转动惯量7

3.6.2 计算加在步进电机转轴上的等效负载转矩Teq7

3.6.3 步进电动机最大静转矩的选定9

3.6.4步进电动机的性能校核9

4 总 结10

参考文献11

致 谢12

川公网安备: 51019002004831号

川公网安备: 51019002004831号