您若下载本次文件,将获得(CAD图纸+word文档)源文件哦!

以下为本次文件的目录及部分图纸截图

【需要其他机械类资料可以联系QQ97666224】

!【详情如下】CAD图纸+设计说明书.doc[10000字,22页]【需要咨询购买全套设计请加QQ97666224】.bat

PDF报告.pdf

中期检查表.doc

和面机的设计.doc

和面机的设计_检测报告.zip

图纸

外文翻译=食品机械加工工艺=4500字符.doc

开题报告-.doc

文献综述.doc

诚信承诺书.doc

长城学院毕业设计(论文)任务书-.doc

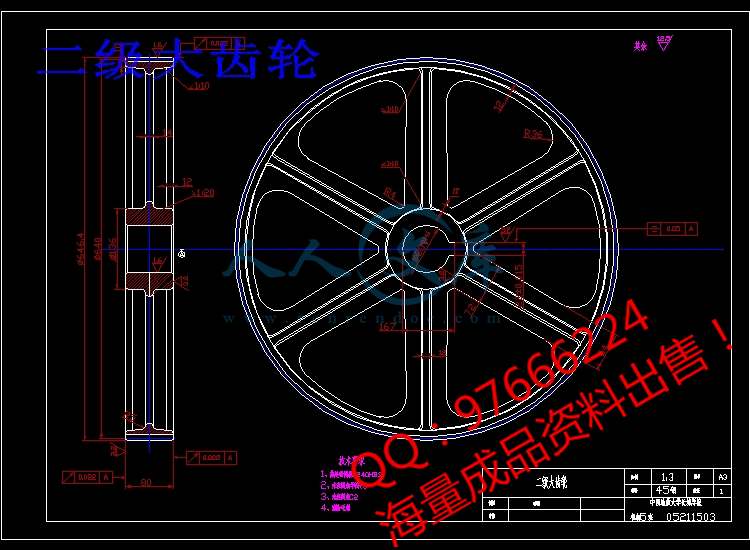

二级大齿轮.dwg

二级齿轮传动轴.dwg

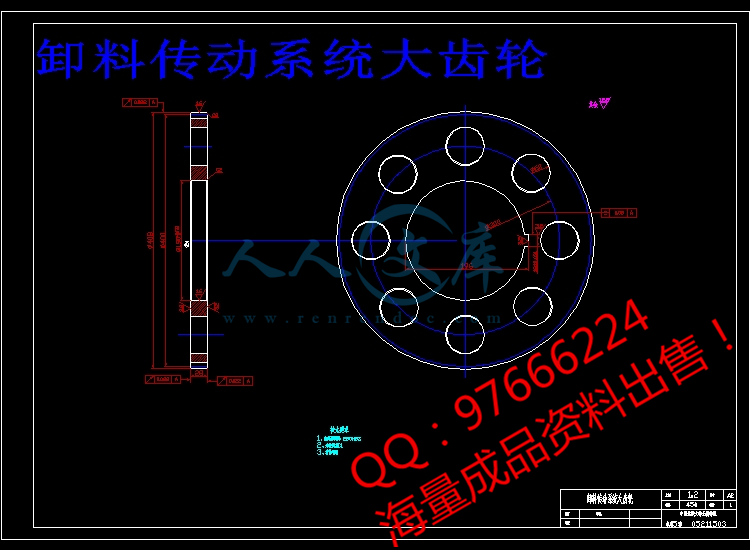

卸料传动系统大齿轮.dwg

大带轮.dwg

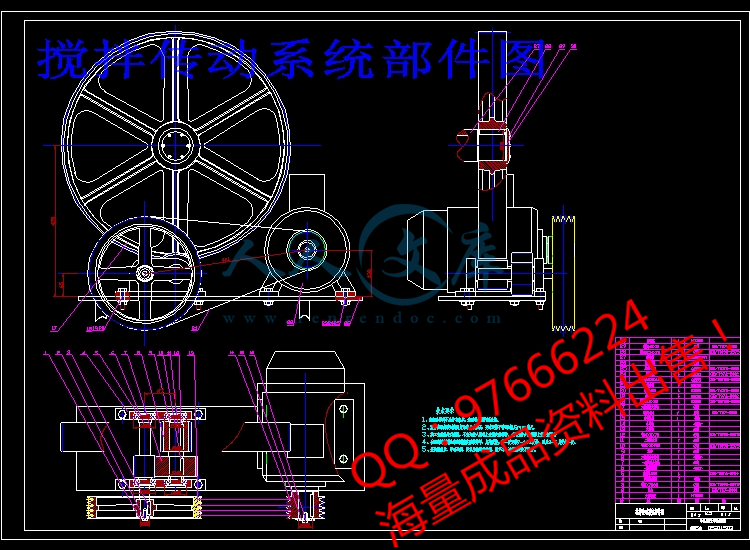

搅拌传动系统部件图.dwg

搅拌器.dwg

搅拌容器.dwg

搅拌轴.dwg

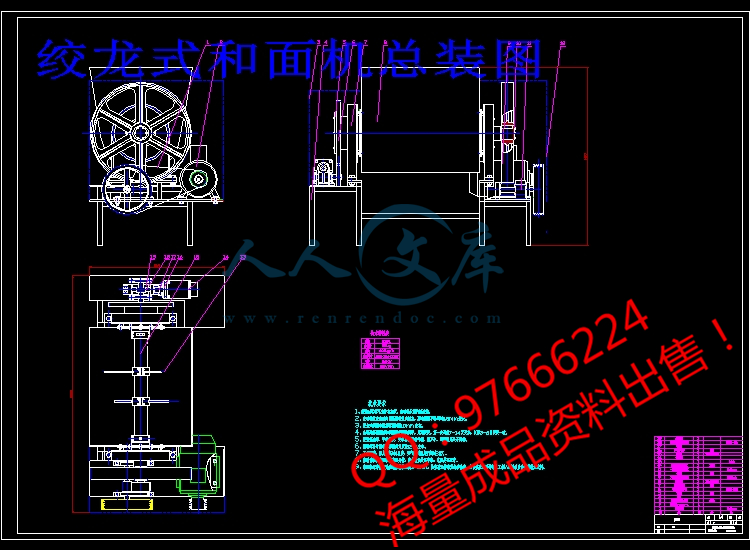

绞龙式和面机总装图.dwg

蜗杆轴.dwg

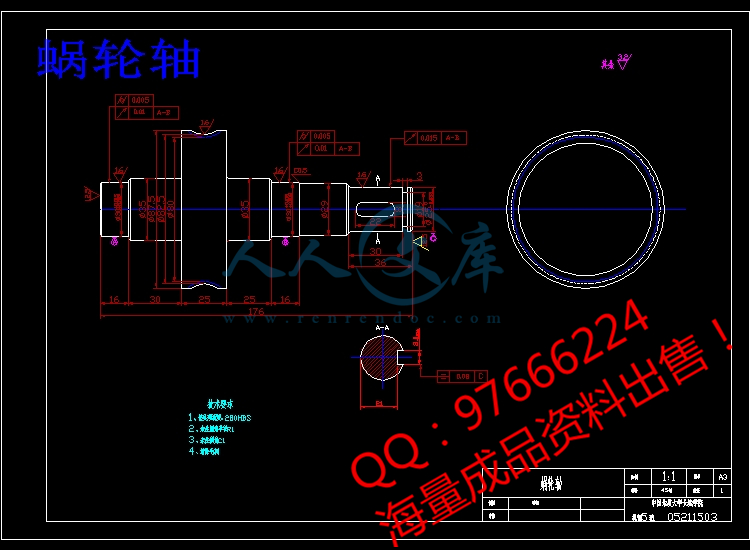

蜗轮轴.dwg

?摘????要????

和面机实际上是一个混合器,它的作用是调制面团,这将所有原始配件,以水,调制混合成符合质量要求的,并适合于加工成型的面团,面包,饼干,蛋糕和主要用于发酵面团调制,食品,夹饼的食品和淀粉面筋生产的粉末。传统的表面的机器上安装了几件叶片的轴,根据主轴的安装形式,可分为垂直和水平的拉伸动作,垂直和面机面团强,适于调制面团弱韧性,拉伸功能水平面团的机器。适用于酥面团调制。水平表面机器主要是指混合容器轴线和旋转搅拌器轴处于水平位置,其特点是,具有结构简单,制造成本低,便于清洗和排出材料的优点,因此在食品加工,如面包,饼干,蛋糕和一些食品工业已被广泛用于面食。在我们的国家和面机产品,它的工作方式多为间歇性,这项工作,机器人工喂养,每个工作周期,手动控制电机的启动和停止,频繁启动电机。这种表面机,在操作人员的劳动强度的工作,需要手动操作和表面的机器,材料,辅助材料的水,以控制,稳定性差的权量,且表面也难以控制一致性的程度,这些都影响了面团的性能稳定性,稳定性会影响最终产品,将影响整个生产线的工作效率。

关键字:绞龙; 多功能; 和面机

Abstract

And surface machine is actually a mixer, its role is modulation of dough, which will all original accessories, mixing with water, modulation into that conform to the quality requirements, and is suitable for machining forming the dough, bread, biscuits, cakes and mainly used for leavening dough modulation, food, clip pie food and starch and gluten the production of powder. The traditional surface machine is installed a few pieces of blade in a shaft, according to the installation form of the spindle, can be divided into vertical and horizontal tensile action two, vertical and surface machine dough is strong, suitable for modulation dough weak toughness, tensile function horizontal flour dough machine. Suitable for modulation of crisp dough. The horizontal surface machine mainly refers to the mixing vessel axis and the agitator axis of rotation in a horizontal position, its characteristic is, has the advantages of simple structure, low manufacturing cost, convenient cleaning and discharging material, so in food processing, such as bread, biscuits, cakes and some food industry has been widely used in pasta.

In our country and surface machine products, the way it works mostly intermittent, this work and machine to artificial feeding, each work cycle, to manually control the motor start and stop, frequent start motor. This surface machine, in the work of the labor intensity of the operation personnel, need hand operation and surface machine, material, auxiliary material and the amount of water to the right of control, poor stability, and the surface is also difficult to control the degree of consistency, these have affected the dough performance stability, stability will affect the final product, will affect the work efficiency of the whole production line. We design the aim of the utility model is directed against the defects of the existing technology, provides a single shaft type automatic and machine, which can realize the continuous automatic and surface operation. The production line is equipped with the starch and gluten and machine, can improve the starch and gluten production line automation. Single shaft type automatic and machine oriented lower starch and gluten production line one step curing machine feeding, can realize the plane layout of starch and gluten host part of the production line, reduce the construction investment, convenient operation, and help to improve work efficiency of starch and gluten powder production line.

Keywords: auger; ?multi function;? and surface machine

目 录

1 绪论3

1.1和面机概述3

1.2和面机设计选择6

2 运动参数、动力参数的设计7

2.1传动系统中传动链的设计及各传动比的分配设计7

2.1.1搅拌浆转速7

2.1.2电动机的主要技术参数选择7

2.2计算各轴的转速7

2.3计算各轴的功率8

2.4计算各轴的转矩8

3 结构设计9

3.1皮带传动设计9

3.1.1计算功率Pc9

3.1.2V带选型9

3.1.3带轮设计9

3.1.4验算带速V9

3.1.5求V带基准长度和中心距10

3.1.6小包角的计算10

3.1.7求带根数Z10

3.1.9带轮结构设计11

3.2蜗轮蜗杆传动结构设计12

3.2.1选择材料12

3.2.2选择蜗杆头数,并估计传动效率12

3.2.4确定使用系12

3.2.5计算转速系数12

3.2.6确定弹性系数12

3.2.7计算寿命系数13

3.2.9确定接触疲劳极限和接触疲劳最小安全系数13

3.2.10计算中心距a13

3.2.12蜗杆的各轴段的直径和长度确定15

3.2.13圆柱蜗杆传动的精度设计15

3.3蜗轮轴的尺寸的确定16

3.4主轴的结构尺寸计算16

3.4.116

3.5主要传动轴受力分析,画出其弯矩图,并且进行相关的校核计算17

3.5.1蜗杆轴受力分析及校核计算17

3.5.2蜗轮轴受力分析及校核计算18

3.5.3蜗轮轴疲劳强度的校核19

3.5.4蜗轮齿根弯曲疲劳强度的校核21

3.5.5蜗杆刚度的校核22

3.5.6相关的其他计算23

3.6主要传动轴承受力分析,强度及轴的寿命演算23

3.6.1轴承受力分析及寿命计算23

3.7浆叶容器及机体的总体结构设计25

4 总结26

参考文献26

致 谢27

川公网安备: 51019002004831号

川公网安备: 51019002004831号