您若下载本次文件,将获得(CAD图纸+word文档)源文件哦!

以下为本次文件的目录及部分图纸截图

【需要其他机械类资料可以联系QQ97666224】

!【详情如下】CAD图纸+设计说明书.doc[11000字,34页]【需要咨询购买全套设计请加QQ97666224】.bat

任务书 破碎机.doc

复摆颚式破碎机(600X1200)设计.avi

复摆颚式破碎机设计说明书.doc

外文翻译=冻结解冻混凝土耐久性与回收拆迁总comparedto原始骨料混凝土=4000字符.doc

毕业设计文献综述.doc

毕业设计(论文)开题报告.doc

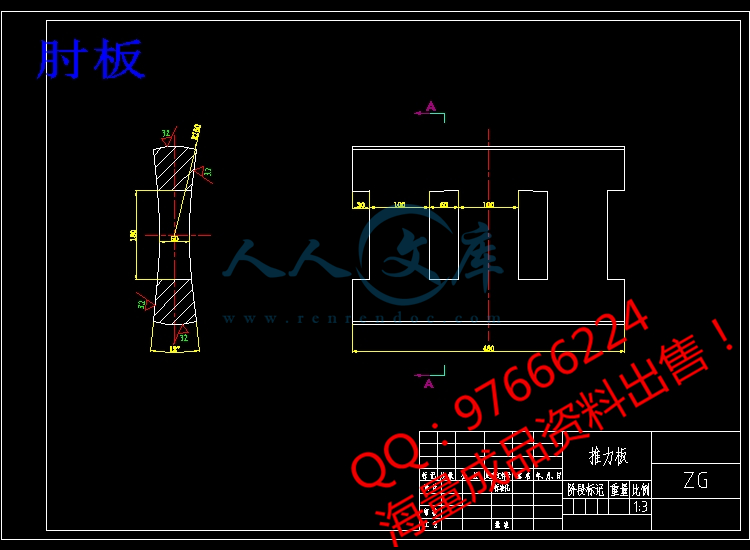

肘板.dwg

装配图.dwg

偏心轴.dwg

动腭.dwg

动腭齿板.dwg

机架.dwg

定腭齿板.dwg

带轮.dwg

目录

第1章 绪论·························································1

1.1 引言··························································1

1.2 复摆颚式破碎机的特点··········································1

1.3 国内外发展现状················································2

第2章 总体设计·····················································4

2.1 基本结构······················································4

2.2 工作原理······················································5

第3章 主要参数的确定···············································6

3.1 已知参数······················································6

3.2 部分参数确定··················································6

3.3 电动机的选择与确定············································7

3.4 确定四连杆机构各杆的长度·····································8

3.5最大破碎力····················································9

3.6各部件的受力分析··············································10

第4章 传动装置的设计··············································12

4.1 带轮的设计···················································12

4.2 偏心轴的设计·················································16

4.3 飞轮设计·····················································19

4.4 轴承的校核···················································20

4.5 键的校核·····················································22

第5章 各基本结构的设计············································23

5.1 动颚的设计··················································23

5.2 尺板的设计···················································25

5.3 推力板的设计·················································27

5.4 破碎腔型的设计···············································28

5.5 机架的设计··················································31

结论······························································33

致谢·······························································34

参考文献··························································35

摘要

破碎机械设备,属于矿山机械范畴。这类机械设备在冶金、建材、化工、能源、交通建设、城市建设和环保等诸多领域有广泛的用途。复摆颚式破碎机可以产生很大的破碎力,从而大大提高了破碎机的性能。它的生产能力高于振动腭式破碎机约30%,同时也因为过大的垂直行程,使得定、动腭衬板(齿板)磨损很快,大大降低了使用寿命。我国自50年代生产腭式破碎机以来,在破碎机设计方面经历了类比、仿制、图解法设计阶段,目前正向计算机辅助设计阶段过渡。国外从上世纪中后期开始利用计算机仿真技术对颚式破碎机机构、腔型、产量和磨损等进行优化,高性发周期,提高了产品的市场竞争力。

本次所设计的复摆颚式破碎机(500×750),就是根据市场调研,对目前市场上现有的破碎机,通过了解客户的需求,通过加以改进创新而得出的。

关键词:振动 腭式 激振器

bstract

Crushing machine, which belongs to the category of mining machinery. This kind of mechanical equipment is widely used in metallurgy, building materials, chemical industry, energy, traffic construction, city construction and environmental protection and many other fields. The vibratory crusher can produce crushing force big, thus greatly improving the performance of crusher. Vibration jaw crusher production capacity is higher than that of simple pendulum jaw crusher is about 30%, but also because the vertical stroke is too large, the set, the movable palate plate (plate) wear out quickly, greatly reduce the service life. Since the 50's production of jaw crusher, the crusher design experience analogy, imitation, graphic design stage, is currently the computer aided design of phase transition. Foreign countries started using computer simulation technology to the jaw crusher, cavity, yield and wear are optimized from the mid-20th century, high hair period, improve the market competitiveness of products.

The design by the compound pendulum jiaw crusher is according to research ,with the existing crusher on the marker at present, by understanding the need of customers, through improved innovation.

Keywords: compound ;jaw type ;plate crusher

川公网安备: 51019002004831号

川公网安备: 51019002004831号