变速箱盖机械加工工艺设计及其数控加工编程

摘要

本设计研究的零件是变速箱盖。其加工工艺的可行性、合理性、先进性将直接影响零件的质量、生产成本、使用性能和寿命。数控加工技术集传统的机械制造、计算机技术、现代控制技术、传感检测技术、信息处理和光机电技术于一体,是现代机械制造技术的基础。数控加工技术的广泛应用,给机械制造业的生产方式和产品结构带来了巨大的变化。数控加工是用数字化信号对机床运动及其加工过程进行控制的一种方法。数控加工技术包含了数控加工与编程、金属加工工艺、CAD/CAM软件操作等多方面知识与经验,其主要任务是计算加工走刀中的刀位点(简称CL点)。随着数控技术的飞速发展,数控技术的水平和普及程度已经成为衡量一个国家综合国力和工业现代化水平的重要标志。本设计是对变速箱盖进行机械加工工艺设计和数控加工编程,首先是设计好加工工艺规程,选择好刀具、主轴转速和实际切削速度等各种因素,然后根据已经选择的刀具、主轴转速和实际切削速度等在Cimatron软件中设置相应的参数进行模拟加工,其具体内容如下:

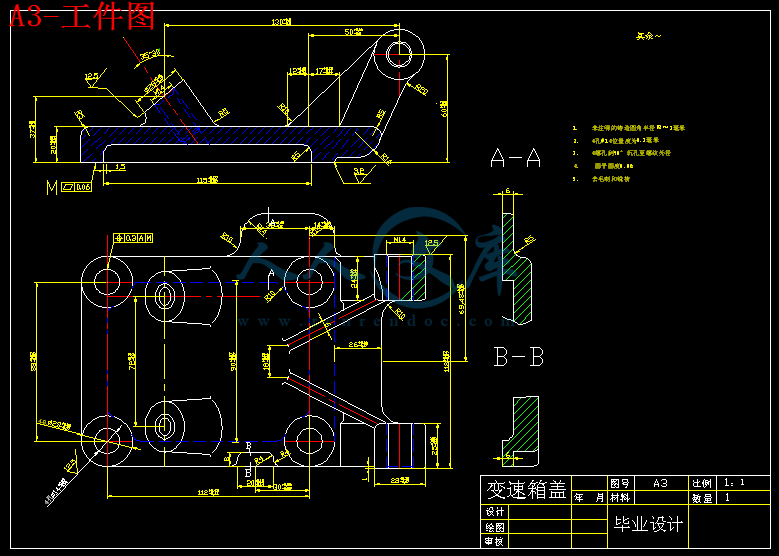

1、通过绘制零件工程图和三维造型图更深一步了解零件的具体形状;

2、根据设计零件的质量要求和技术要求设计了零件的加工工艺规程,选择了合理的定位基准,并填写了工序卡片上的相关内容;

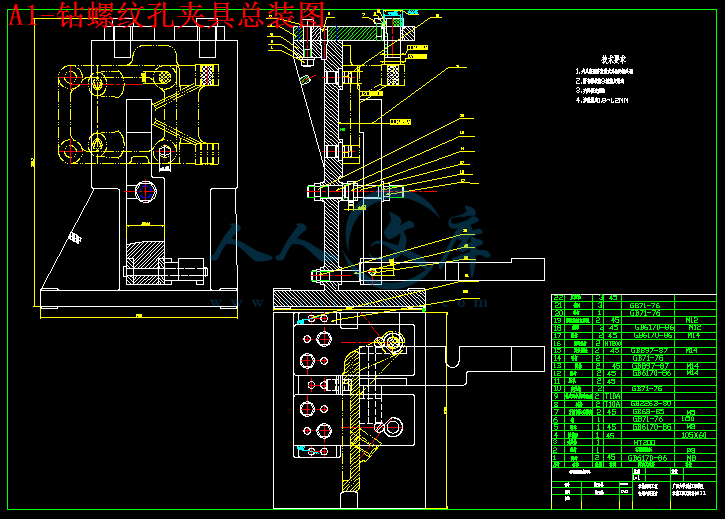

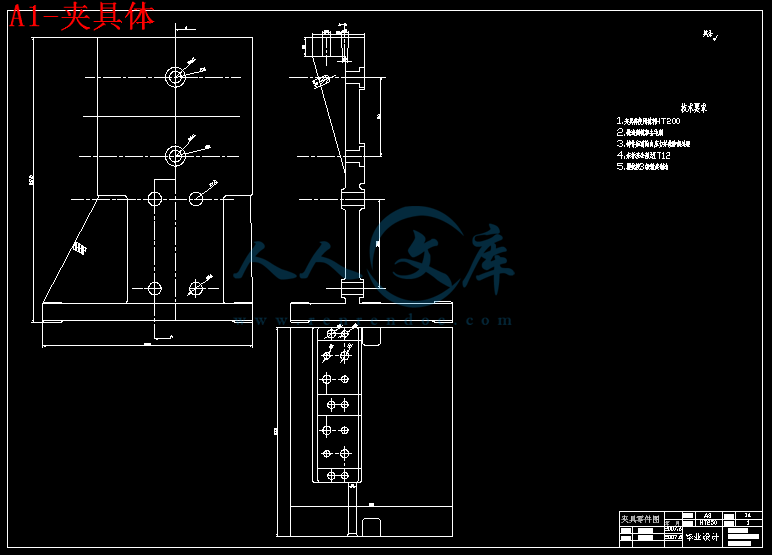

3、设计一道工序的夹具图,并绘制夹具主要零件图和装配图;

4、在Cimatron软件对工件进行了数控模拟加工,并且进行了仿真校验。最后还对零件的数控加工进行后置处理,生成了零件加工的G代码。

关键词:机械加工工艺设计 夹具设计 数控加工

Mechanical machining design of the lid of Speed change box and its numerical control processing programming Summary

The design is about the lid of Speed change box. The reasonableness, advanced components of its machining process , will directly affect the quality, production costs, the use of performance and longevity. Numerical control processing technology gets the traditional machinery manufacturing, computer technology, modern control technology, sensor testing technology, information processing and optical technology together,it is the foundation of modern machinery manufacturing technology. The widespread application of numerical control processing technology has brought about tremendous changes to production methods and product structure of the machinery manufacturing. numerical control processing is a method that uses numerical information to control the movement and processing of machine tools. numerical control processing technology incorporates numerical control processing and programming, metal machining, CAD/CAM operation sofeware, and other aspects of knowledge and experience, its main task is to calculate the tool points (short for the CL points) of the tool spaces during processing. With the rapid development of numerical control technology, its level and popularization has become an important symbol which is a measure of a country's comprehensive national strength and industrial modernization level. This design is to design mechanical machining and numerical control processing programming for the lid of Speed change box, The first is to design a machining, select cuttersand the rotational speed of main axis and the actual cutting speed, and so on, and then base on the chose cutters, the rotational speed of main axis and the actual cutting speed, and so on, install in the corresponding parameters ,simulate processing with Cimatron software, Its specific contents are as follows :

1. I further understood the concrete shape of the components by drawing engineering plat and three dimensional modeling chart of this components.

2. The machining of part has been designed according to the quality requirement and technical design component and a reasonable benchmark positioning also has been chosen , and then complete the processes of the relevant cards.

3. I designed a jig chart of a working procedure, and drew up the main detail drawing and the assembly drawing of the jig.

4. A numerical control simulation processing has been done in Cimatron software.Finally processing the numerical control processing of the part and the . G code generated.

Keywords:Mechanical machining design, Jig design, Numerical control processing

目录

第一章 绪论…………………………………………………………………1

1.1变速箱…………………………………………………………1

1.2 机械加工…………………………………………………………2

1.3 数控加工技术……………………………………………………3

1.4 本章小结…………………………………………………………8

第二章 机械加工工艺设计…………………………………………………9

2.1 设计题目…………………………………………………………9

2.2 机械加工工艺……………………………………………………9

2.3 计算生产纲领、确定生产类型…………………………………11

2.4 零件的分析………………………………………………………11

2.5 确定毛坯的制造方法,初步确定毛坯形状……………………14

2.6 工艺规程的设计…………………………………………………15

2.7 确定切削用量基本工时(机动时间)…………………………21

第三章 夹具的设计…………………………………………………………34

3.1 问题的提出………………………………………………………34

3.2 夹具设计的相关计算…………………………………………..34

3.3 夹具结构设计与操作说明………………………………………37

第四章 数控加工编程………………………………………………………38

4.1 零件的数控加工分析……………………………………………38

4.2 应用软件的介绍…………………………………………………39

4.3 零件的造型及导入过程…………………………………………41

4.4 零件的数控加工及仿真校验过程………………………………41

4.5 G代码的生………………………………………………………63

4.6 本章小结…………………………………………………………64

第五章 总结与展望…….……………………………………………………65

5.1 设计的总结………………………………………………65

5.2 展望………………………………………………………………67

参考文献………………………………………………………………………69

附录……………………………………………………………………………71

致谢…………………………………………………………………………..82

第一章 绪论

工艺设计是现代制造业的重要基础工作,是连接产品设计与产品制造的桥梁和纽带。工艺设计的质量和效率直接影响企业制造资源的配置与优化、产品质量、生产组织效率、产品成本与生产周期等方方面面。随着科学技术的迅速发展,机械产品的结构、零件的形状也在不断改进,人们对零件加工质量和加工精度的要求也越来越高。由于产品改型频繁,而且对精度要求高,为了提高生产效率,降低成本,保证产品质量,要求产品不仅有较好的通用性和灵活性,而且应实现加工过程的自动化。采用组合机床、自动机床、仿形机床和自动线,其设备的第一次投资费用高,生产准备时间长,而且不能满足零件形状复杂和改型频繁的要求。于是一种新型的机械加工设备—数控加工机床应运而生。

当前,在机械加工领域数控机床的使用已经非常普及,各个工厂企业都有不少数控机床,数控机床的出现使工业生产设备产生了本质的变革。在机械加工生产中,数控技术的应用不仅减轻了工人的劳动强度,还大大提高了产品质量和精度。

川公网安备: 51019002004831号

川公网安备: 51019002004831号