摘 要

本课题是车床拨叉上螺纹底孔加工钻床夹具设计,而车床拨叉它位于车床变速机构中,主要起换档,使主轴回转运动按照工作者的要求工作,获得所需的速度和扭矩的作用。

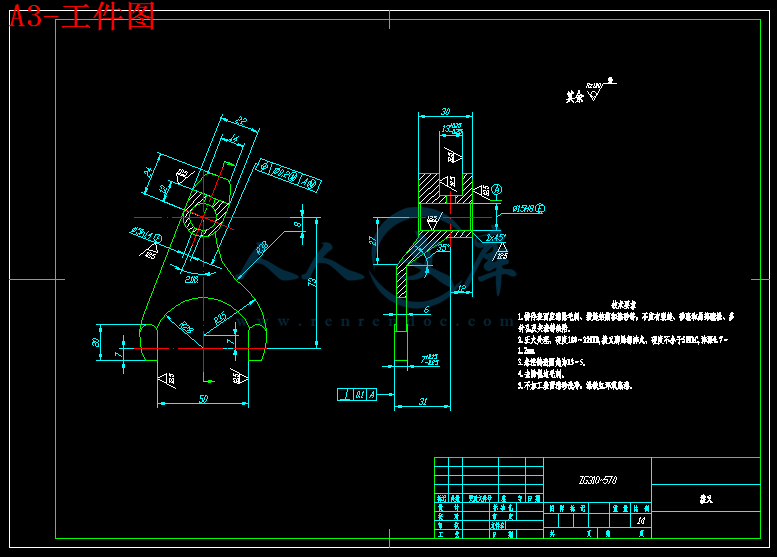

本设计中,根据拨叉尺寸公差、形状和位置公差、表面粗糙度、技术要求、工件材料、毛坯类型、热处理与表面保护等要求来设计。夹具的总体设计包括从方案制定到总装配图的设计的全部过程。包括确定工件的定位,选择或设计定位元件,计算定位误差;确定刀具的导引和对刀方式,选取或色痕迹导引元件或对刀元件;确定工件的夹紧方式,选择或设计夹紧机构或装置,计算夹紧力;确定夹具体及其他装置的结构类型等。

通过合理的设计,在保证零件加工质量前提下,提高生产效率,降低消耗,以取得较好的经济效益和社会效益。

关键词:夹具,设计,钻床,螺纹底孔;

Abstract

The topic is The design of the drilling machine fixture for Processing lathe shifting fort upper thread bottom hole, and lathe shifting fort located in the lathe speed institutions, mainly from the shift so that the spindle rotary movement of workers in accordance with the requirements of work, have the necessary speed and torque Role.

The design, based on tolerance shifting fort size, shape and location of tolerance, surface roughness, technical requirements, the workpiece material, rough type, heat treatment and surface protection and other requirements of the design. Fixture for the overall design, including programming from the assembly to the design of the entire process. Including the identification of the workpiece location, location choice or design components, calculated positioning error; determine the tool and guided the knife, or select the color traces of knife-guided components or components; determine the workpiece clamping, choice or design clamping Or device, calculated clamping force; identify specific folders and other devices, such as the type of structure.

Through rational design, to ensure the quality of parts processing premise, increase production efficiency and reduce consumption, to achieve better economic and social benefits.

Keywords: Fixture, Design,Drilling Machine,Thread Bottom Hole;

目录

摘 要I

AbstractII

第一章 绪论1

1.1 背景1

1.2 夹具的特点1

1.3 研究夹具的目的和意义4

1.4 论文构成及研究内容4

1.4.1 论文构成4

1.4.2 本设计的主要内容及要求5

第二章 机床夹具概述6

2.1 夹具的现状及生产对其提出新的要求6

2.2 夹具的国内外现状和发展趋势6

2.3 现代夹具的发展发向7

2.3.1 精密化7

2.3.2 高效化7

2.3.3 柔性化7

2.3.4 标准化7

2.4 机床夹具及其功用8

2.4.1 机床夹具8

2.4.2 机床夹具的功能8

2.5 机床夹具在机械加工中的作用8

2.6 机床夹具组成和分类9

2.6.1 机床夹具的基本组成部分9

2.6.2 机床夹具的其他组成部分9

2.7 机床夹具的分类10

2.7.1 按夹具的通用特性分类10

2.7.2 按夹具使用的机床分类11

2.8 机床夹具设计特点11

第三章 夹具设计12

3.1 夹具设计概述12

3.1.1 机床夹具设计的基本要求和步骤12

3.1.2 机床夹具的分类和组成13

3.1.3 工件安装与获得加工精度的方法13

3.1.4 工件在夹具中的定位原理14

3.1.5 常见定位方式及定位元件14

3.1.6 工件在夹具中的夹紧原理15

3.1.7 确定刀具位置及钻套的选择16

3.1.8 夹具总图的绘制及标注18

3.1.9 机床夹具总图上尺寸的标注19

3.1.10 机床夹具总图上技术条件的标注19

3.1.11 机床夹具调刀尺寸的标注20

3.2 夹具设计21

3.2.1 问题的提出21

3.2.2 定位方案设计22

3.2.3 定位元件设计23

3.2.4 切削力与夹紧力计算23

3.2.5 定位误差计算23

3.2.6 导向方案选择24

3.2.7 导向元件设计24

3.2.8 导向误差计算24

3.2.9 夹紧装置的设计24

3.2.10 设计夹具体25

3.2.11 夹具工作原理25

3.3 夹具在安装和操作时应注意的事项25

3.3.1 夹具的安装25

3.3.2 夹具在操作时应注意的事项26

3.4 夹具可行性分析26

3.4.1 夹具的经济效益分析26

3.4.2 夹具的可行性27

第四章 总结28

致谢29

参考文献30

科技译文31

第一章 绪论

1.1 背景

夹具最早出现在1787年,至今经历了三个发展阶段。第一阶段表现为夹具与人的结合。在工业发展初期,机械制造的精度较低,机械产品工件的制造质量主要依赖劳动者个人的经验和手艺,而夹具仅仅作为加工工艺过程中的一种辅助工具;第二阶段是随着机床、汽车、飞机等制造业的发展,夹具的门类才逐步发展齐全。夹具的定位、夹紧、导向(或对刀)元件的结构也日趋完善,逐渐发展成为系统的主要工艺装备之一;第三阶段,即近代由于世界科学技术的进步及社会生产力的迅速提高,夹具在系统中占据相当重要的地位。这一阶段的主要特征表现为夹具与机床的紧密结合。

川公网安备: 51019002004831号

川公网安备: 51019002004831号