摘要

尾座体是车床上的重要的部件之一,是车床上用以支撑轴类零件车削加工和实施钻孔的主要车床附件。本文针对某类给定的尾座体进行了加工工艺与工装的设计,完成了以下工作:

1.概述了尾座体的技术和现状发展;

2.对尾座体进行了工艺分析,并提出了两种方案进行比较;

3.编制了尾座体的工艺规程,完成了其工序卡的设计;

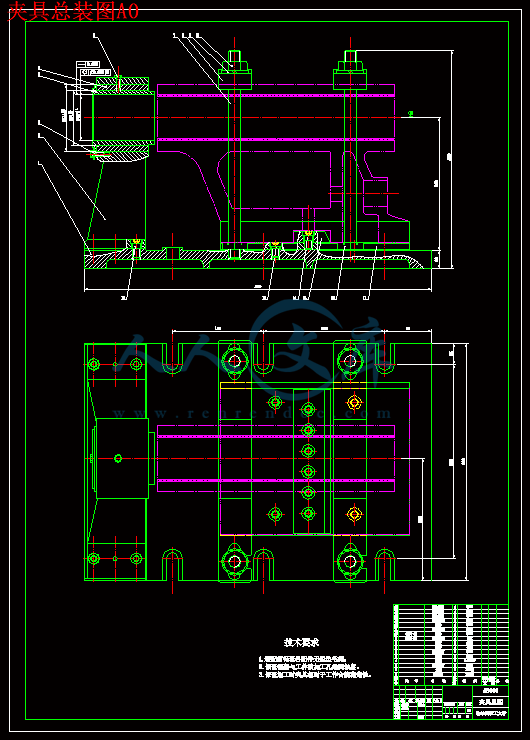

4.针对工艺中的某重要工序,设计完成了一套镗孔夹具,包括定位元件,夹紧机构、对刀块、夹具体的设计并分析了定位误差。

关键词 设计;工装;工艺;尾座体

Lather tail the craft work of the body pack a design

Abstract

stalk spare parts, the car pares to process the main lather enclosure that drills a hole with implementation.This text aims at a certain the tail body giving certainly carried on to process the design that craft and work pack and completed once work:

1.All said a tail the technique and present condition development of the body;

2.Carried on craft analysis to the tail body, and put forward two kinds of projects to carry on a comparison;

3.Drew up a tail body of craft regulations, completed the design of its work preface card;

4.Aim at a craft in of some important work preface, designed to complete a set of Xian slot tongs, including fixed position component, clipped tight organization, to the knife piece, clip a concrete design and analyzed a fixed position error margin.

Keywords design; clamping; craft; tailstock

目录

摘要I

AbstractII

第1章 绪论1

1.1 课题来源1

1.2 课题背景及发展趋势1

1.3 夹具的基本结构及夹具设计的内容1

1.4 本章小结2

第2章 尾座体加工工艺规程设计3

2.1 零件的分析3

2.1.1 零件的作用3

2.1.2 零件的工艺分析3

2.2 加工的主要问题和工艺过程设计所应采取的相应措施4

2.2.1 确定毛坯的制造形式4

2.2.2 基面的选择4

2.2.3 确定工艺路线4

2.2.4 机械加工余量、工序尺寸及毛坯尺寸的确定5

2.2.5 确定主要工序工程中的切削用量7

2.3 本章小结17

第3章 专用夹具设计18

3.1 镗Ф75H6孔夹具设计18

3.1.1 定位基准的选择18

3.1.2 夹紧力的计算18

3.1.3 夹紧元件及动力装置确定19

3.1.4 镗套、镗模板及夹具体设计19

3.1.5 夹具精度及定位误差分析20

3.1.6 夹具设计及操作的简要说明20

3.2 本章小结22

结论23

致谢24

参考文献25

附录27

第1章绪论

1.1课题来源

本课题来源于指导教师所给众多题目之一。

1.2课题背景及发展趋势

加工工艺及夹具毕业设计是对所学专业知识的一次巩固,是在进行社会实践之前对所学各课程的一次深入的综合性的总复习,也是理论联系实际的训练。

机床夹具已成为机械加工中的重要装备。机床夹具的设计和使用是促进生产发展的重要工艺措施之一。随着我国机械工业生产的不断发展,机床夹具的改进和创造已成为广大机械工人和技术人员在技术革新中的一项重要任务。

材料、结构、工艺是产品设计的物质技术基础,一方面,技术制约着设计;另一方面,技术也推动着设计。从设计美学的观点看,技术不仅仅是物质基础还具有其本身的“功能”作用,只要善于应用材料的特性,予以相应的结构形式和适当的加工工艺,就能够创造出实用,美观,经济的产品,即在产品中发挥技术潜在的“功能”。

技术是产品形态发展的先导,新材料,新工艺的出现,必然给产品带来新的结构,新的形态和新的造型风格。材料,加工工艺,结构,产品形象有机地联系在一起的,某个环节的变革,便会引起整个机体的变化。

工业的迅速发展,对产品的品种和生产率提出了愈来愈高的要求,使多品种,对中小批生产作为机械生产的主流,为了适应机械生产的这种发展趋势,必然对机床夹具提出更高的要求。

川公网安备: 51019002004831号

川公网安备: 51019002004831号