四轴加工中心机械手自动换刀装置设计

4轴加工中心机械手自动换刀装置设计【优秀含9张CAD图纸+机械手毕业设计】

【带任务书+开题报告+中期检查表+文献综述+外文翻译】【32页@正文11600字】【详情如下】【需要咨询购买全套设计请加QQ1459919609 】.bat

中期检查.doc

任务书.doc

外文翻译.doc

开题报告.doc

文献综述.doc

设计说明书.doc

诚信承诺书.doc

A0机械手.dwg

A0机械手驱动装置.dwg

A0驱动外形.dwg

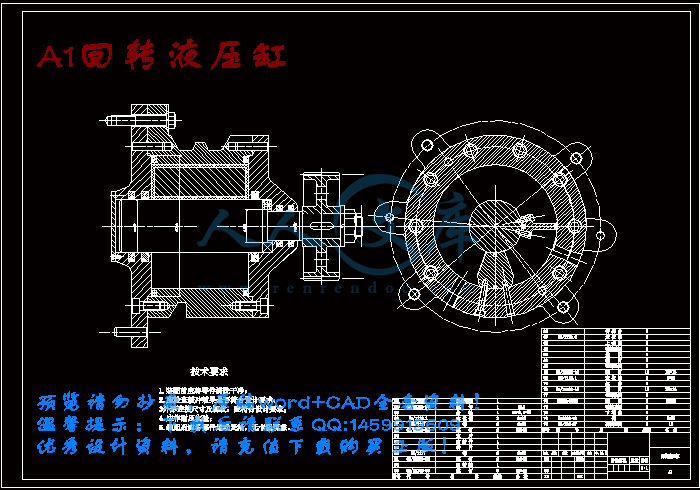

A1回转液压缸.dwg

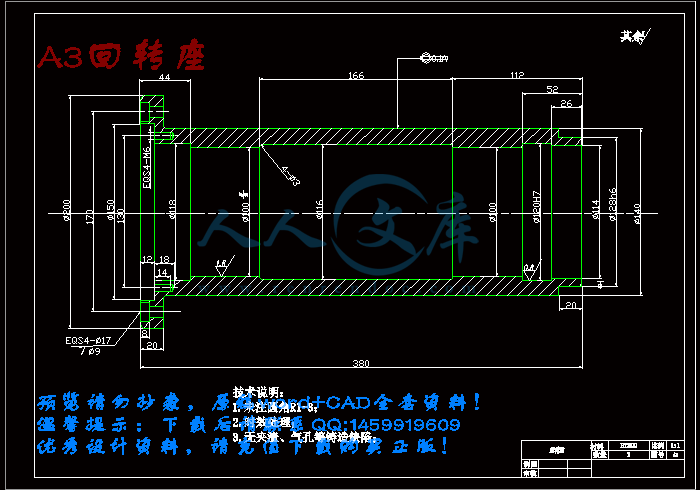

A3回转座.dwg

A3支架.dwg

A3轴承端盖.dwg

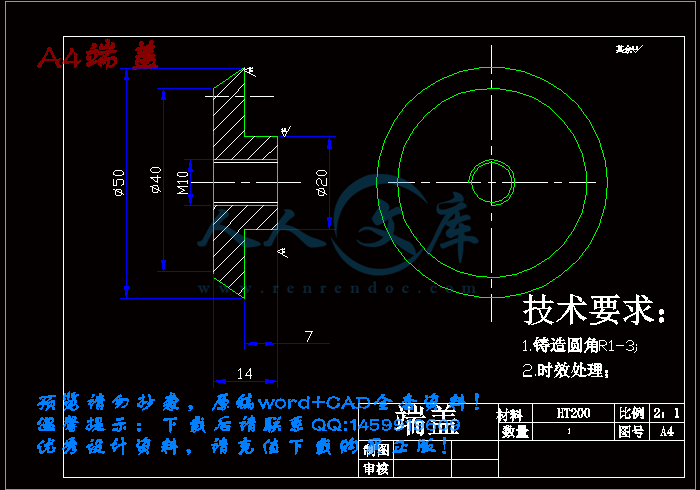

A4端盖.dwg

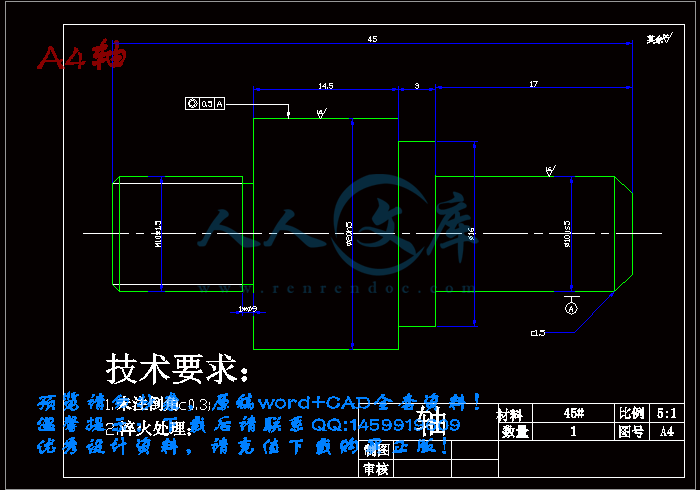

A4轴.dwg

任务书

毕业设计(论文)题目4轴加工中心机械手自动换刀装置设计

毕业设计(论文)主要内容和要求:

1. 刀库容量: 24把刀

2. 刀柄型号: 标准刀柄

3. 刀具最大直径: 120㎜

4. 刀具最大重量: 1.5kg

5. 刀具重量: 11㎏

毕业设计(论文)主要参考资料:

《机械设计》、《机械原理》、《液压传动》、《机械制图》、《材料力学》、

《机械设计手册》、《互换性与测量技术基础》

毕业设计(论文)应完成的主要工作:

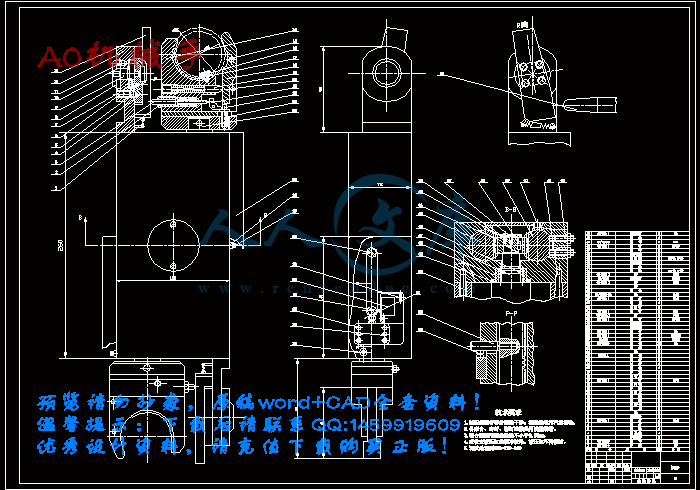

机械手图纸

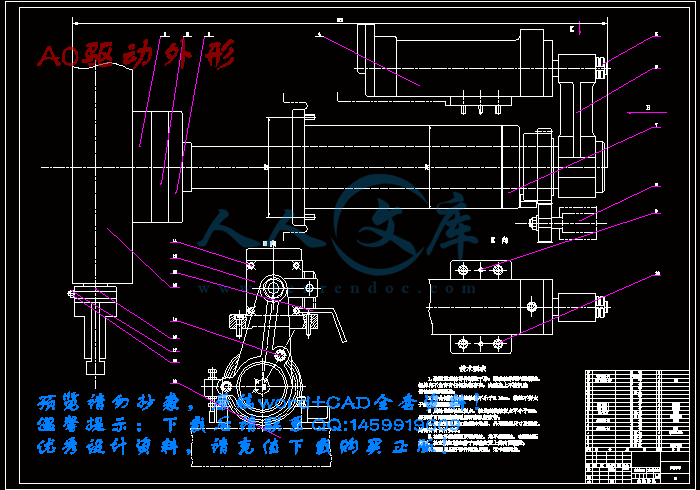

机械手驱动装置图纸

回转液压缸、回转座图纸

轴、端盖、轴承端盖图纸

设计说明书一份

毕业设计(论文)进度安排:

序号毕业设计(论文)各阶段内容时间安排备注

1确定毕业设计题目,查阅并收集整理相关资料2014年12月到2015年1月

2确定研究方法,分析处理数据,撰写论文大纲2015年1月到20015年3月

3构思论文内容,设计开题报告,完成论文初稿的撰写2015年3月到2015年4月

4论文修改润色,完成论文终稿,送交指导老师评审,进行答辩。

摘 要

机械手是自动换刀装置中交换刀具的主要工具,它担负着把刀库上的刀具送到主轴上,再把主轴上已用过的刀具返回刀库上的任务。设计思路是用机械手的动作来实现对加工中心的换刀,机械手的转动有回转液压缸运来实现,其动力则由驱动系统实现。加工中心的自动换刀装置,通常是由刀库和机械手组成,它是加工中心的象征,又是加工中心成败的关键环节。因此各加工中心制造厂家都在下大力研制动作迅速、可靠性高的自动换刀装置,以求在激烈的竞争中取得好效益,自动换刀装置是加工中心的核心内容,各厂家都在保密,极少公开有关资料,尤其机械手部分更是如此。这种机械手的拔刀、插刀动作,大都由油缸动作来完成。根据结构要求,可以采用油缸动,活塞固定;或活塞动,油缸固定的结构形式。整个机械手由机械臂伸缩机构,机械爪开合机构,回转机构及装卸刀具直线运动机构组成。

关键词: 加工中心; 机械手; 刀库; 机械臂

Abstract

Manipulator is automatically change tool device the main tool to exchange tool, it bears on the knife library on the tool to spindle, and then the spindle has used tool returns tasks on tool store. Design idea is to use robots to achieve the action machining center, the rotation of the manipulator change cutters are shipped turn hydraulic cylinder, its power is realized by drive system implementation. Machining center, the automatic cutter replacement device is usually composed by knife library and manipulator, it is the symbol of processing center, it is crucial to the success of the processing center link. So the processing center manufactures are developed rapidly next vigorously, high reliability of action, in order to be automatic cutter replacement device in the fierce competition and achieved good benefit, automatically change tool device is the core content of machining center, the manufacturers are confidential, seldom publicly about material, especially manipulator part is even more so. This manipulator, a sword, inserted knife action by oil cylinder action mostly to finish. According to the structural requirement, can use oil cylinder move, piston fixed; Or the piston move, oil cylinder fixed structure. The whole manipulator, by mechanical arm telescopic institution of mechanical claw opening-closing institutions, rotary institutions and loading and unloading tool linear motion mechanism composition.

Key words: machining centre; manipulator; magazine tool; mechanical arm

目 录

1 前言1

2 加工中心的总体布局1

2.1 技术条件1

2.2 总体布局2

2.3 卧式加工中心的机械结构:2

3 换刀机械手的设计2

3.1 刀具的交换装置2

3.1.1 自动换刀装置2

3.1.2 机械手的种类3

3.1.3 手爪的选择8

3.1.4 刀具的夹持8

3.2 机械手的驱动装置9

3.2.1 手臂的伸缩运动:9

3.2.2 手爪的开合(见自动换刀机械手图)9

3.2.3 回转运动(见驱动装置图)10

3.2.4 直线运动10

3.3 设计计算10

3.3.1 手指夹紧力的计算:10

3.3.2 齿轮的设计11

3.3.3 轴的设计15

3.3.4 轴承的设计20

3.3.5 弹簧的设计22

4 结论26

参考文献27

致 谢28

1 前言

本次设计的题目是加工中心的自动换刀装置中的核心部件---机械手的设计。机械手是加工中心自动换刀装置中交换刀具的主要工具,它担负着把刀库上的刀具送到主轴上,并且把主轴上已用过的刀具放回刀库上的任务。

设计此机械手的目的是为了使加工中心能够更快的的工作,使加工中心能够得到更加充分的利用,以实现其的价值;再者,由于使用机械手换刀,减少了由于人工换刀带来的生产效率低,并且容易出事故的弊端。

本次设计的内容主要有回转液压缸装置和机械运动的驱动系统,对于其中动作的实现则由电气控制来实现。

由于本人的实际能力及学到的知识有限,在设计中必然会存在有很多缺陷,望老师们能多加指导与指正。

川公网安备: 51019002004831号

川公网安备: 51019002004831号