摘 要

连杆是柴油机的主要传动件之一,本文主要论述了连杆的加工工艺及其夹具设计。连杆的尺寸精度、形状精度以及位置精度的要求都很高,而连杆的刚性比较差,容易产生变形,因此在安排工艺过程时,就需要把各主要表面的粗精加工工序分开。逐步减少加工余量、切削力及内应力的作用,并修正加工后的变形,就能最后达到零件的技术要求。

机械加工工艺是企业上品种、上质量、上水平,加速产品更新,提高经济效益的技术保障。然而夹具又是制造系统的重要部分,工艺对夹具的要求也会提高,专用夹具、成组夹具、组合夹具和随行夹具都朝着柔性化、自动化、标准化、通用化和高效化方向发展以满足加工要求。所以对机械的加工工艺及夹具设计具有十分重要的意义。

关键词: 连杆;加工工艺;夹具设计

Abstract

The connecting rod is one of the main driving medium of diesel engine, this text expounds mainly the machining technology and the design of clamping device of the connecting rod. The precision of size, the precision of profile and the precision of position , of the connecting rod is demanded highly , and the rigidity of the connecting rod is not enough, easy to deform, so arranging the craft course, need to separate the each main and superficial thick finish machining process. Reduce the function of processing the surplus , cutting force and internal stress progressively , revise the deformation after processing, can reach the specification requirement for the part finally

Keywords: connecting rod;deformination;processing technology;design of

clamping device

目录

摘 要III

AbstractIV

绪论1

1 零件的造型2

1.1零件造型软件介绍2

1.2零件造型过程2

2 零件的分析7

2.1 零件的作用7

2.2 零件的工艺分析7

2.2.1 零件图样分析7

2.2.2 工艺分析7

3 工艺规程设计9

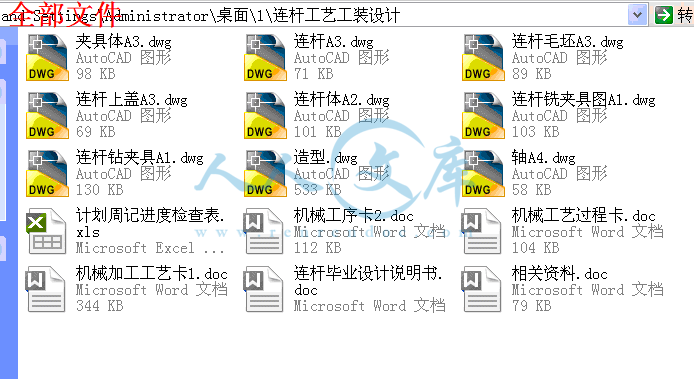

3.1 确定毛坯的制造形式9

3.2 定位基准的选择9

3.2.1 粗基准的选择9

3.2.2 精基准的选择10

3.3 拟定工艺路线10

3.3.1 工艺路线方案一11

3.3.2 工艺路线方案二11

3.4 工艺方案的比较与分析12

3.5 机械加工余量、工序尺寸及毛坯尺寸的确定14

3.5.1 大小头两端表面14

3.5.2 99±0.01mm的两侧面14

3.5.3 内孔Φ25mm14

3.5.4 内孔Φ50mm14

3.5.5 油孔Φ5mm14

3.5.6 油孔Φ1.5mm14

3.5.7 油孔Φ4mm15

3.5.8 油孔Φ8mm15

3.5.9 螺栓孔Φ12.22mm15

3.5.10 螺栓孔Φ13mm15

3.5.11 锪孔Φ20mm15

3.5.12 镗孔Φ58±0.05mm15

3.5.13 镗孔Φ26±0.05mm16

3.5.14 镗孔Φ65.5mm16

3.5.15 镗孔Φ29.5mm16

3.5.16 铣连杆上盖5mm×8mm斜槽16

3.5.17 铣连杆体5mm×8mm斜槽16

3.6 确定切削用量及工时定额16

4 专用夹具设计45

4.1 问题的提出45

4.2 夹具设计45

4.2.1 定位基准的选择45

4.3 切削力及夹紧力计算45

4.2.2 定位误差分析46

5 存在的问题与展望47

5.1 存在的问题47

5.2 展望47

47

毕业设计小结48

致 谢49

参考文献50

绪论

机械的加工工艺及夹具设计是在完成了大学的全部课程之后,进行的一次理论联系实际的综合运用,使我对专业知识、技能有了进一步的提高,为以后从事专业技术的工作打下基础。机械加工工艺是实现产品设计,保证产品质量、节约能源、降低成本的重要手段,是企业进行生产准备,计划调度、加工操作、生产安全、技术检测和健全劳动组织的重要依据,也是企业上品种、上质量、上水平,加速产品更新,提高经济效益的技术保证。然而夹具又是制造系统的重要组成部分,不论是传统制造,还是现代制造系统,夹具都是十分重要的。因此,好的夹具设计可以提高产品劳动生产率,保证和提高加工精度,降低生产成本等,还可以扩大机床的使用范围,从而使产品在保证精度的前提下提高效率、降低成本。当今激烈的市场竞争和企业信息化的要求,企业对夹具的设计及制造提出了更高的要求。所以对机械的加工工艺及夹具设计具有十分重要的意义。

夹具从产生到现在,大约可以分为三个阶段:第一个阶段主要表现在夹具与人的结合上,这是夹具主要是作为人的单纯的辅助工具,是加工过程加速和趋于完善;第二阶段,夹具成为人与机床之间的桥梁,夹具的机能发生变化,它主要用于工件的定位和夹紧。人们越来越认识到,夹具与操作人员改进工作及机床性能的提高有着密切的关系,所以对夹具引起了重视;第三阶段表现为夹具与机床的结合,夹具作为机床的一部分,成为机械加工中不可缺少的工艺装备。

川公网安备: 51019002004831号

川公网安备: 51019002004831号