摘要

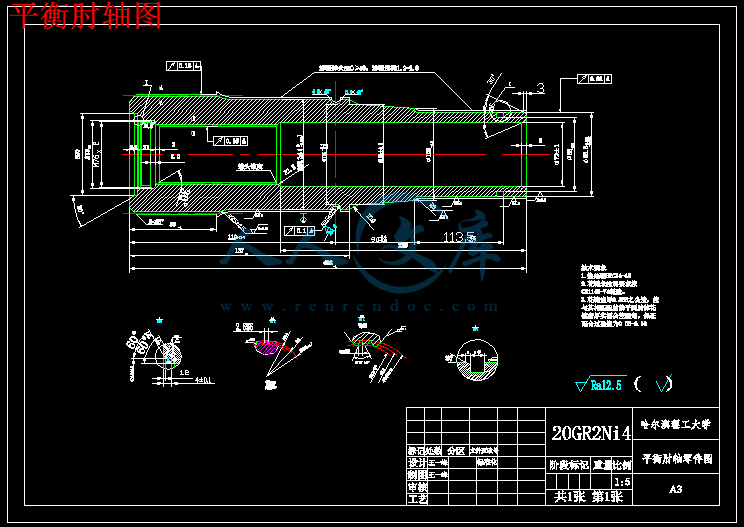

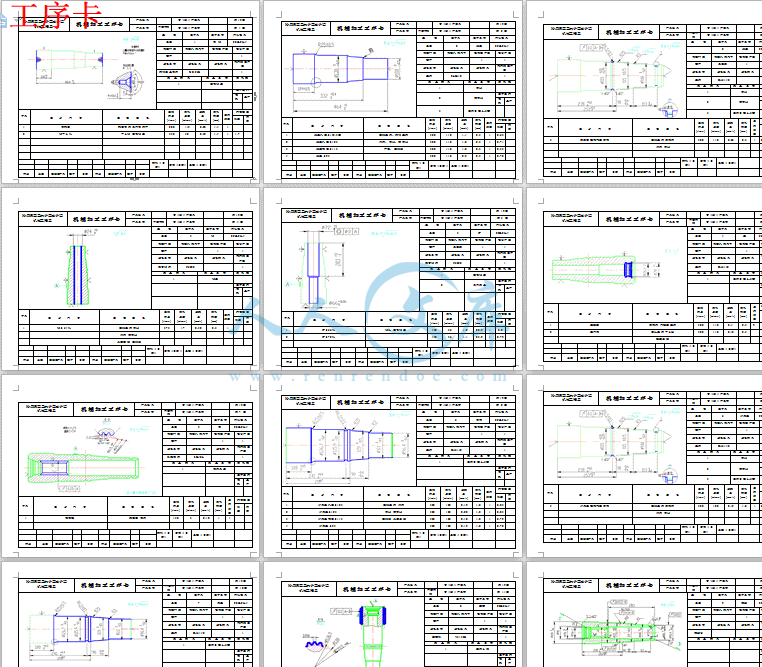

某车辆在初样车试车过程中发现平衡肘轴有开裂现象。经化学成分分析、金相检测、宏观断口分析、综合分析等分析检测手段,最终确定裂纹是在试车过程中形成于连接销孔底部圆锥面与孔侧圆柱面相交的圆周处,在随后的试车过程中发生疲劳扩展。本论文针对所分析的结论,对原始设计工艺进行了研究,并作了一定的改进,来制定平衡肘轴制作的工艺规程和工装的设计。平衡轴上外表面存在键槽,滚珠槽和外花键。内孔有内花键,内外表面粗糙度要求较高,种类较多,加工工艺较为复杂。由于平衡肘轴在坦克行驶中的重要作用,要求表面较硬,所以需要表面渗碳,而且表面粗糙度要求较高,需要外表面磨削加工。工艺过程是改变生产对象的形状、尺寸、相对位置和性质等,使其成为成品或半成品的过程。工艺规程是指规定产品或零件在生产过程中,由毛坯准备到成品包装入库,经过企业各有关部门或工序的先后顺序。工艺设计是指编制各种工艺文件盒设计工艺装备等的过程。平衡肘轴作为平衡轴的一种,具有典型轴类零件的特点,并有内通孔和花键。通过对平衡肘轴工艺规程的制定和工装的设计,并制定工序卡,能够深入研究轴类零件内外表面的加工方法和热处理工艺的排序。

关键词 平衡肘轴;工艺规程;工装设计

Balance Shaft Techniques Procedure and Tooling Design

Abstract

In the early prototype of a vehicle found during commissioning balanced elbow axis cracking phenomenon. The chemical composition analysis, metallurgical testing, macro-fracture analysis, a comprehensive analysis and other analytical detection methods, and ultimately determine the crack is formed in the testing process in connection with the pin hole at the bottom of the conical surface intersects the bore side circumference of the cylindrical surface, in the subsequent test fatigue occurs during the expansion. This thesis focuses on the analysis of the conclusions of the original design process was studied, and made some improvements, to develop balanced elbow axis making process planning and tooling design. The outer surface of the existence of the balance shaft keyway, the ball groove and the external splines. Bore with internal spline, inside and outside surface roughness is higher, more categories, more complex process. As balance in the tank with the elbow axis of the important role, requiring a hard surface, so it is necessary carburizing, and the surface roughness is higher, the outer surface grinding needs. Production process is to change the shape of the object, size, relative position and nature, making the process of finished or semi-finished products. Process specification refers to products or parts required in the production process, from the preparation to the finished blank packaging and storage, through the business processes of the department or the order. Process design refers to the preparation of a variety of technical documents such as technical equipment box design process. Balance balance shaft axis as an elbow, with the typical characteristics of shaft, and a through-hole and the inner splines. By balancing the elbow axis process specification development and tooling design and develop processes card, can penetrate into the inner and outer surfaces of shaft parts processing methods and heat treatment process of the sort.

Keywords Balance Shaft; Process planning;Tooling design

目录

摘要I

AbstractII

第1章 绪论1

1.1 课题背景1

1.1.1 课题来源1

1.1.2 课题的研究的背景和意义1

1.1.3 课题的总体内容2

1.2 国内外研究现状2

1.3 本章小结3

第2章 零件分析4

2.1 功能及连接情况4

2.2 零件的结构特点4

2.3 零件的技术要求分析4

2.4 加工精度要求4

2.5 热处理要求5

2.6 其他要求5

2.7 本章小结5

第3章 工艺规程的设计6

3.1 工艺规程概念、原则及依据6

3.1.1 工艺规程概念6

3.1.2 制订工艺规程的原则6

3.1.3 制订工艺规程的主要依据6

3.1.4 零件规程的设计6

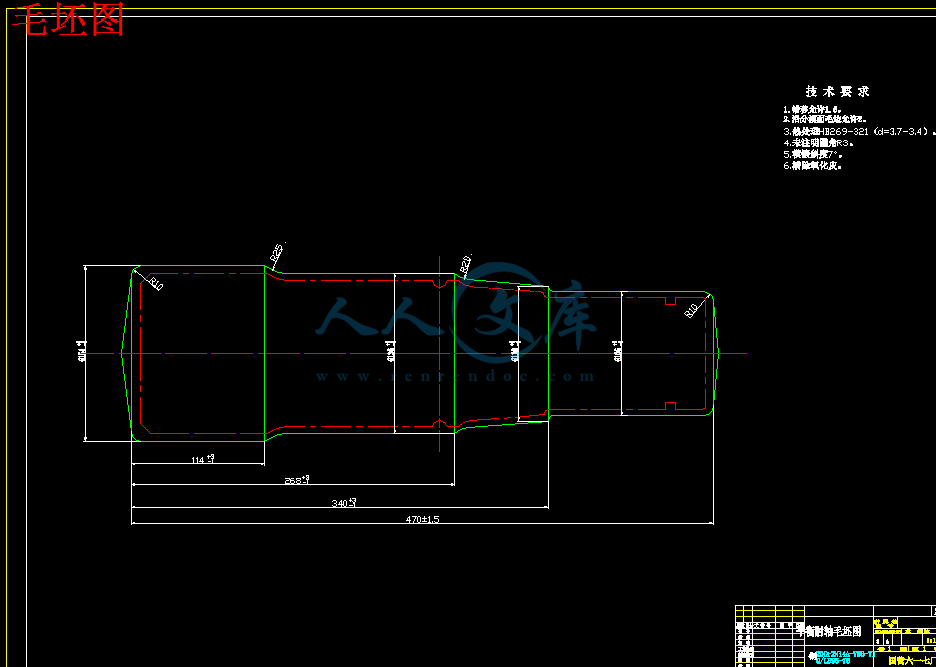

3.2 毛坯8

3.2.1 确定零件毛坯的制造形式8

3.2.2 影响毛坯选择的因素8

3.2.3 毛坯材料的确定8

3.2.4 毛坯的技术要求9

3.3 基准的选择9

3.3.1 粗加工基准的选择9

3.3.2 半精加工基准的选择10

3.3.3 精加工基准的选择10

3.4 工艺规程的安排10

3.4.1 工艺规程的拟定10

3.4.2 加工阶段的划分10

3.4.3 加工方法的选择11

3.4.4 加工工序安排11

3.5 加工余量的选择12

3.6 切削用量的选择12

3.6.1 粗加工时12

3.6.2 半精加工时12

3.6.3 精加工时13

3.6.4 光整加工时13

3.7 工序的确定13

3.8 机床的选择与功率核算24

3.8.1 机床的选择24

3.8.2 机床功率核算24

3.9 刀具的选用24

3.9.1 刀具的选择24

3.9.2 依据原则24

3.10 本章小结26

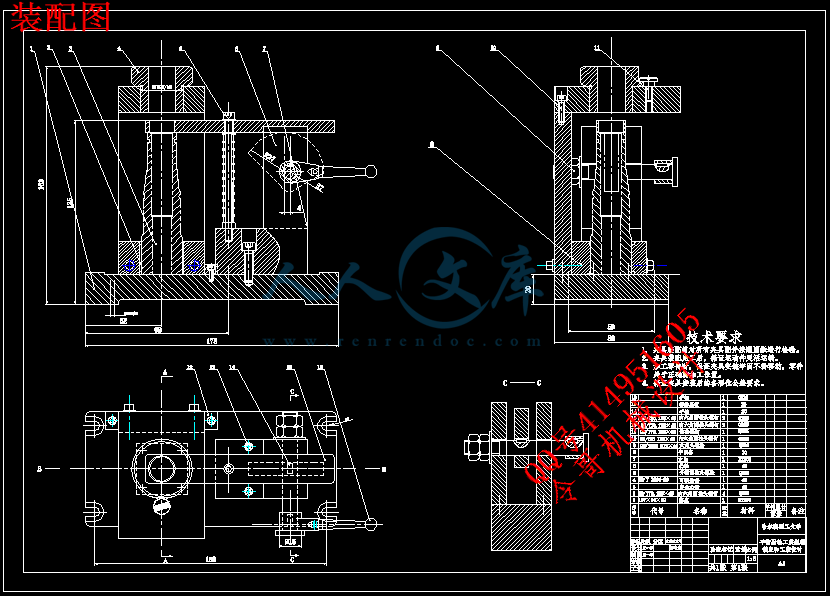

第4章 夹具的设计27

4.1 定位机构27

4.2 夹紧机构27

4.3 导向装置的选择28

4.4 绘制夹具装配图28

4.5 定位误差设计29

4.5.1 误差分析29

4.5.2 定位误差的计算29

结论30

致谢31

参考文献32

附录33

第1章绪论

1.1课题背景

1.1.1课题来源

内蒙古第一机械制造(集团)有限公司计量检测研究所“平衡肘轴裂纹原因分析”。

川公网安备: 51019002004831号

川公网安备: 51019002004831号