摘 要

活塞是汽车发动机中的一个主要零件,承受着交变的机械负荷和热负荷,发动机中工作条件最恶劣的关键零部件之一,随着汽车整车对发动机动力性、经济性和可靠性的要求越来越严格,活塞也就更加需要具备良好的耐热性、耐磨性、导向性和密封性。为满足零件的功能,其加工质量尤为关键。

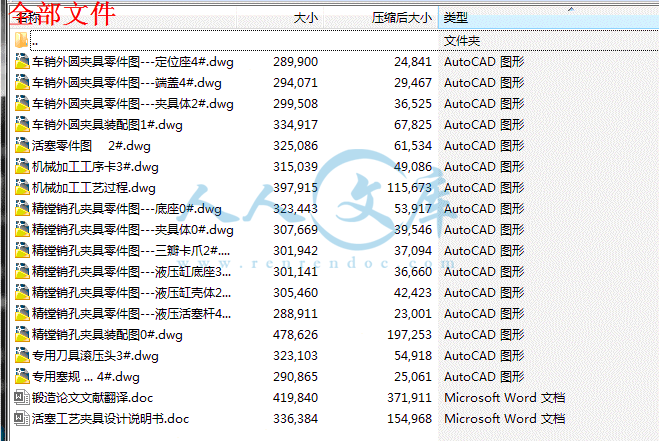

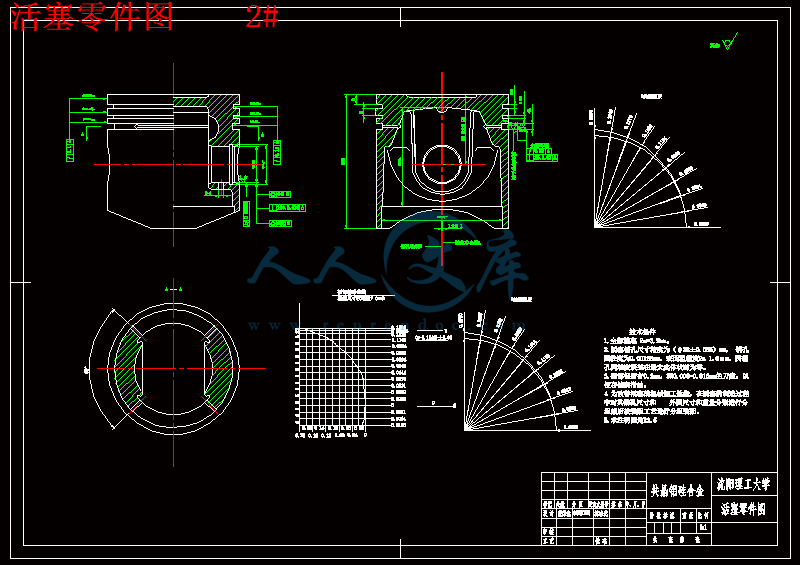

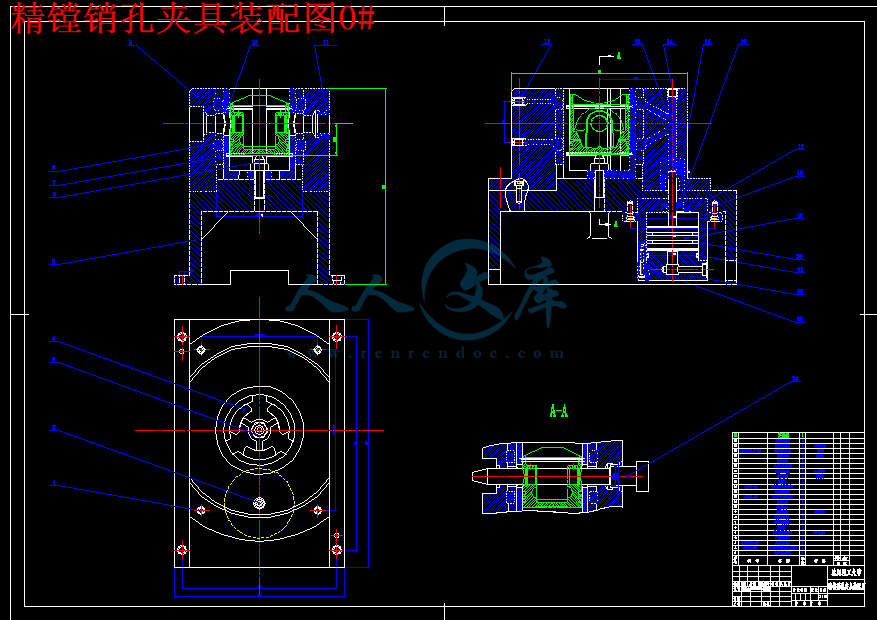

基于活塞特有的机械加工工艺特点,单靠一般的通用机床很难满足活塞的高精度要求,因此专用的设备及工艺装备在活塞切削加工中使用广泛。其功能和精度也直接影响了最终产品关键的质量指标。本论文主要是针对活塞加工的工艺规程及加工中所使用的典型专用夹具、刀具和量具的设计进行详细说明。根据活塞工作条件、结构特点以及技术要求等因素,编制了两套工艺方案,择优制定了活塞加工的工艺规程,并设计了两套关键工序中 专用设备所使用的专用夹具以及专用的刀具和检具各一套。

关键词 活塞;工艺;夹具;刀具;检具

Abstract

Piston is a main section of automotive engine, which endure cross-changing mechanical load and heat load. It is also one of the key parts which have the worst working environment in the engine. Piston need to have well nature of heat-resistant, wearable, oriented and airproof along with the whole auto required more and stricter about the engine’s charter of momentum,economy and reliability. the quality of processing are so important for satisfied the parts function.

Based on the technologic characters of mechanical working which belong to piston, it is difficult to satisfy the high precision demand of piston only relaying on a general common machine tool. So the special equipment and technological outfit are extensive use in piston cutting processing.The quality of the final products is also directly influenced by function and accuracy. This paper is primary aimed at technological procedure of the piston and give a detail illustration about typical special fixture, cutter and measuring implement in processing. According to piston working condition, structural trait, technological request and some factors, people weave two technological proposals. The better proposal will selected to make technological procedure of the piston, and design a special fixture, a special cutter and a test tool respectively in processing of special equipment in two key procedures.

Key words piston; technology; fixture; cutter; test tool

目 录

绪 论 ……………………………………………………………. 1

1 活塞的工艺分析 ……………………………………………….. .2

1.1 活塞的作用 ……………………………………………… .2

1.2 活塞的特点 ………………………………………………. 2

1.3 活塞的主要技术条件分析 ……………………………………3

2 活塞的工艺规程的设计 …………………………………………...4

2.1 活塞的材料和毛坯的制造 ……………………………………4

2.2 定位基面的选择 ……………………………………………4

2.3 制定工艺路线 ……………………………………………...5

2.4 机械加工余量、工序尺寸和毛坯尺寸的确定 ……………………9

2.5 确定切削用量及基本工时 ……………………………………10

2.6 重点工序的加工说明 ………………………………………..12

3 专用夹具的设计 …………………………………………………14

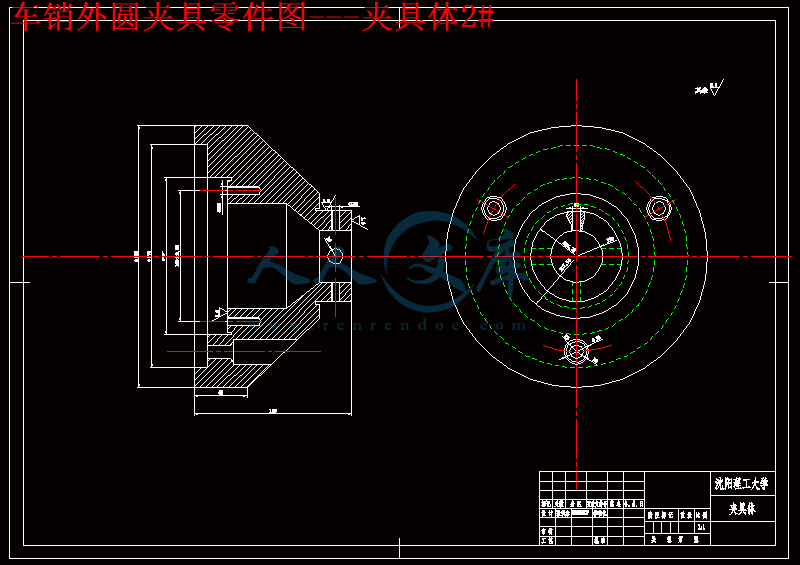

3.1 车削外圆夹具的设计 ………………………………………...15 3.1.1 工序加工要求及工艺分析 ………………………………….15 3.1.2 夹具定位方案的确定(定位基准、定位元件的选择) …………..15 3.1.3 夹具夹紧机构的设计 ……………………………………...16 3.1.4 夹具体的设计 ……………………………………………17 3.2 精镗销孔夹具的设计 ………………………………………...17 3.2.1 工序加工要求及工艺分析 ………………………………….17 3.2.2 夹具定位方案的确定(定位基准、定位元件的选择) ………….17 3.2.3 夹具的工作原理 ………………………………………….18 3.2.4 夹紧液压系统设计 ………………………………………..18

4 专用量具的设计 …………………………………………………20

5 专用刀具的设计 …………………………………………………22

5.1 滚压加工的介绍 ……………………………………………...22

5.2 专用刀具(滚压头)的结构 …………………………………..22

5.3 滚压头的工作原理 …………………………………………..23

结 论 ……………………………………………………………..24

致 谢 ……………………………………………………………..25

参考文献 ………………………………………………………….26

附录 A 英文原文 ………………………………………………….27

附录 B 汉语翻译 ………………………………………………….36

绪 论

随着人类社会机械化、自动化程度的日益提高,内燃机作为一种可移动的动力源已广泛应用于生产和生活的各个领域。活塞是内燃机的关键零件,其结构复杂,加工工序多。目前,国内活塞行业所用加工机床除引进外,大多为国产通用机床或在此基础上进行较为简易改造的设备,一条生产线一般由17-20台设备组成,采用粗放型生产方式,设备精度低,工件需多次装夹定位,加工过程累积误差大,工件精度低、稳定性差、废品率高、劳动生产率低,生产现状和设备远远不能满足市场竞争的需要。国内机床行业虽然也为活塞行业提供了一定数量的活塞专用机床,但由于对活塞加工工艺缺乏深入的了解,也未能摆脱活塞行业原有的生产加工方式。在国外工业发达国家的一些实力较强的活塞制造公司,如德国MAHLE公司、KS公司、英国AE公司、日本AR7等,其活塞加工己实现了工序优化组合,一人多机数控化生产,机加工过程中周转环节少,工艺条件稳定,产品尺寸精度高。对于批量大的活塞品种,他们将其加工设备连成数控全自动生产线,设备基本上全是自行设计制造。由于国外机床行业雄厚的基础,他们采用了一定数量的机床通用零部件,专业性较强的零部件仍靠自主开发设计。设计过程中,他们充分利用国外机床行业的先进设计及制造技术对机床进行优化,如有限元法等动、静态设计分析,使其能够满足活塞高精加工的要求。

川公网安备: 51019002004831号

川公网安备: 51019002004831号