摘 要

工艺规程设计以及典型的加工工序的夹具设计。本文对一个常规工艺设计及的步骤做了详细阐述。在此基础上对零件加工要求进行分析,最终确定毛坯的材料,选择定位基准,并留出适当的加工余量。综合上述分析可以制定出零件加工工艺路线中的具体参数进行计算,例如基本的切削用量的计算,并根据计算结果选择机床,验算机床功率,此外,计算加工过程中的机动时间和辅助时间也是必不可少的。

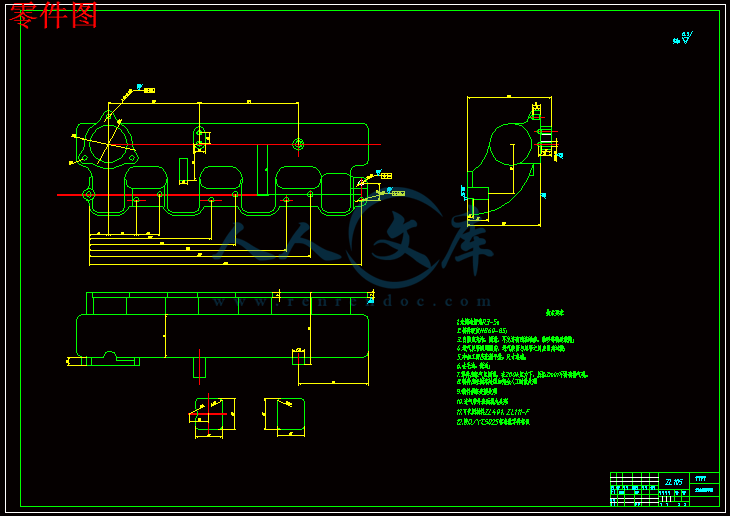

机械加工工艺过程,是指用机械加工方法逐步改变毛坯形态(形状、尺寸和表面质量),使之成为合格零件所进行的全部过程。

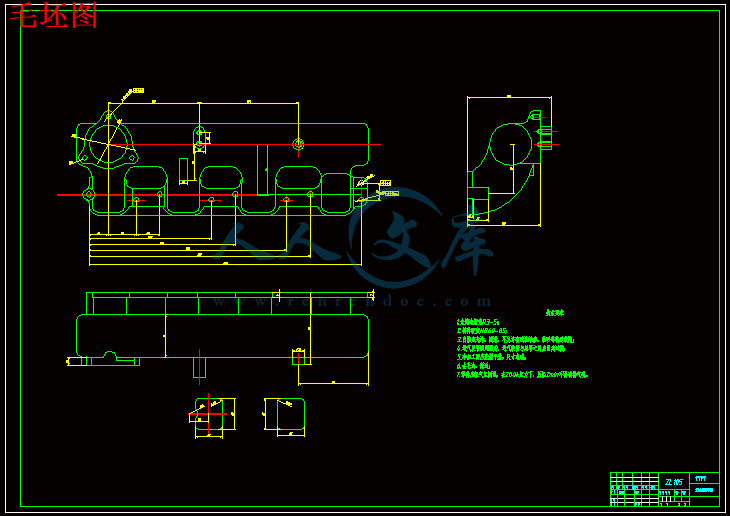

机械加工工艺过程包括结构工艺性分析、毛坯的选择、基准的选择、加工余量的确定、工艺路线的拟定、工序尺寸及公差的确定和加工设备的选择等。工艺路线是连接产品设计和制造的纽带,它是一项经验性强、技巧性高、涉及多方面的知识和信息的工作,因此工艺路线设计极其复杂,其中,加工顺序的先后、热处理的安排和工序的集中还是工序的集中与分散是工艺人员在拟定工艺路线时的原则性问题。

为了提高劳动生产率,保证加工质量和改善劳动条件,需要设计专用的夹具。在夹具设计中,不仅要追求其其结构的合理性,更重要的是核算其加工精度的准确性。影响工件加工精度的因素很多,且种类复杂。本夹具的设计是完成定位设计、夹紧设计等,以及如何将这些机构装配起来形成一个整体 装配过程。结构方案确定以后,绘制了主要的零件图装配图。

关键词:加工工艺;切削用量;工艺计算;夹具设计。

Abstract

This design mainly includes two aspects of content, namely the intake pipe processing process planning and typical processing process of fixture design. In this paper a conventional process design and steps to do a detailed description. On the basis of the parts processing requirements analysis, with a final determination of blank materials, choose the locating datum, and set aside the proper machining allowance. A combination of the analysis can work out the parts processing process route in the specific parameters calculation, such as basic of cutting parameter calculation, and according to the calculated results choose machine tool, the checking machine power, in addition, the calculation process, mobile time and auxiliary time is also essential.

Mechanical processing, it is to point to by machining methods gradually change the blank form (shape, size and surface quality), make it become the qualified the process all parts.

Mechanical processing process including structure analysis technology, the choice of blank, the choice of machining allowance benchmark, the determination, process route of the recommended, and the determination of the procedure sizes tolerance and processing equipment choice, etc. Process line is the connection product design and the manufacture of the link, it is a critical skill, high, strong a wide range of knowledge and information work, so process route design is extremely complex, among them, the processing order has the arrangement and working procedure, heat treatment process of concentration or centralized and decentralized is in planning process engineering process route of principle problem.

In order to improve labor productivity, guarantee the processing quality and improve working conditions, and need to design a special fixture. The fixture design, we not only need to pursue the rationality of the structure, more important is the accuracy of accounting the machining accuracy. The influence the machining accuracy of many factors, and species complex. This fixture design is complete orientation design, clamping design, and how these institutions together to form a whole assembly process. Structure plan later, rendering the main parts drawing assembly drawing.

Key words: process, the cutting dosages, process calculation, fixture design.

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 本课题研究的内容及意义1

1.2 国内外发展情况1

1.3本课题应达到的要求2

2 零件的分析3

2.1 零件的功用3

2.2 零件的工艺分析3

3 零件工艺规程设计5

3.1 确定零件生产类型5

3.2 材料的选择5

3.3 确定零件毛坯的制造形式5

3.4 拟定零件的机械加工工艺路线5

3.4.1 定位基准的选择5

3.4.2 零件表面加工方法的选择6

3.4.3 零件各表面加工顺序的确定6

3.4.4 工序的组合6

3.5 工序设计7

3.6工艺计算8

3.6.1 铣后表面8

3.6.2 钻后表面上的孔10

3.6.3 铣前表面12

3.6.4 钻前表面上的孔13

3.6.5 铣上表面14

3.6.6 钻上表面的孔15

3.6.7 铣凸台面17

3.6.8 铣左表面17

3.6.9 钻左表面上的孔18

4 夹具设计20

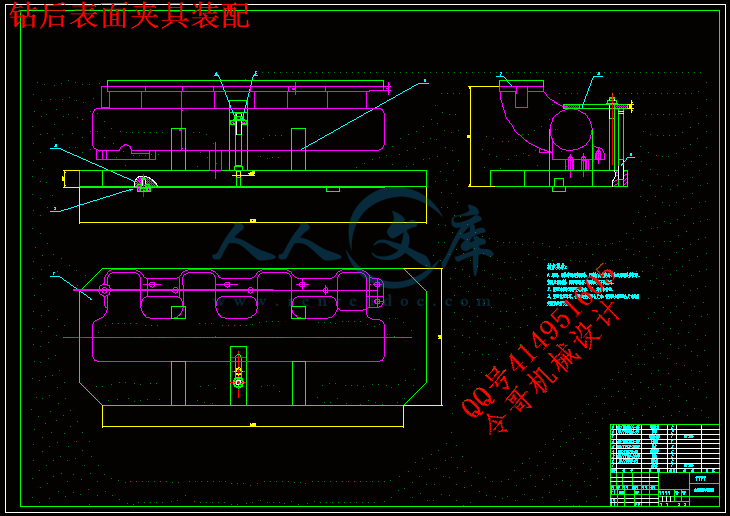

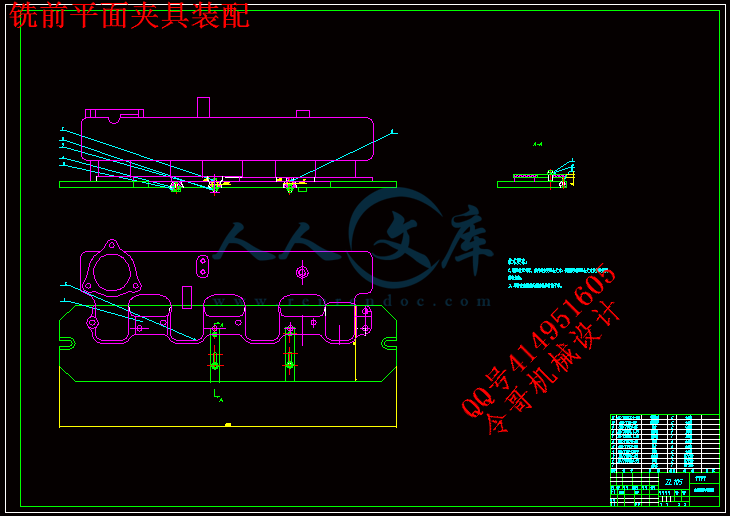

4.1 夹具设计概述20

4.2 机床夹具的分类20

4.3 机床夹具的基本组成20

4.4 夹具设计20

4.4.1 铣后表面夹具设计23

4.4.2 铣前表面夹具设计23

4.4.3 钻后表面孔夹具设计24

4.5 夹具装配图上的标注及技术要求25

4.6 定位误差的分析与计算26

4.6.1 定位误差的分析26

4.6.2 定位误差的计算27

4.7 夹紧力的的分析与计算29

5 结论与展望31

5.1 结论31

5.2 不足之处及未来的展望31

致 谢31

参考文献33

1 绪论

1.1 本课题研究的内容及意义

本课题研究的内容是:工艺过程的重要性;云内内燃机进气管的机械加工工艺规程的编制,包括工艺路线设计、工艺设计、编制工艺规程文件;系列夹具设计。

工艺是机械产品设计、制造过程中的重要组成部分,工艺设计的好坏直接影响产品的最终制造质量和整个生产系统的优化状况。

在国民经济的各个领域,各个行业中广泛使用者大量的机床、机器、仪器及工具等,这些工艺装备都是有机械制造行业提供的。机械制造业的主要任务就是围绕各种材料的加工要求,研究其加工工艺并设计和制造各种工艺装备,机械制造工业是国民经济各部门的装备部,它不仅为传统产业提供了现代化的设备,同时也是计算机、通信等新兴产业的基础。

机械制造业的兴衰直接影响和制约了工业、农业、交通、航天、信息和国防各部门的生产技术水平,进而影响着一个国家的综合生产实力。

川公网安备: 51019002004831号

川公网安备: 51019002004831号