目 录

1 引言……………………………………………………………………………………1

2 零件分析………………………………………………………………………………2

2.1 零件的生产纲领及生产类型………………………………………………………2

2.2 零件的作用…………………………………………………………………………2

2.3 零件的加工工艺分析………………………………………………………………2

2.4 零件主要技术条件分析及技术关键问题…………………………………………2

3 铸造工艺方案设计……………………………………………………………………4

3.1 确定毛坯的成形方法………………………………………………………………4

3.2 铸件结构工艺性分析………………………………………………………………4

3.3 铸造工艺方案的确定………………………………………………………………4

3.4 铸造工艺参数的确定………………………………………………………………5

3.5 型芯设计……………………………………………………………………………5

4 机械加工工艺规程设计………………………………………………………………7

4.1 基面的选择…………………………………………………………………………7

4.2 表面加工方案的选择………………………………………………………………7

4.3 制订机械加工工艺路线……………………………………………………………8

4.4 确定机械加工余量及工序尺寸……………………………………………………9

4.5 确定切削用量及基本工时……………………………………………………… 13

5 夹具设计…………………………………………………………………………… 35

5.1 工件分析………………………………………………………………………… 35

5.2 绘制夹具总体图………………………………………………………………… 41

6 组合机床设计……………………………………………………………………… 42

6.1 组合机床结构方案的确定……………………………………………………… 42

6.2 被加工零件工序图绘制………………………………………………………… 42

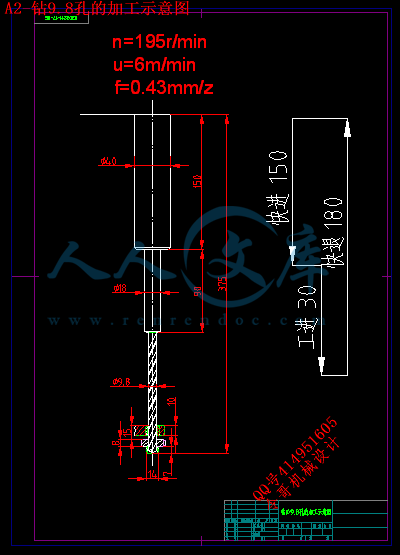

6.3 被加工零件加工示意图绘制…………………………………………………… 42

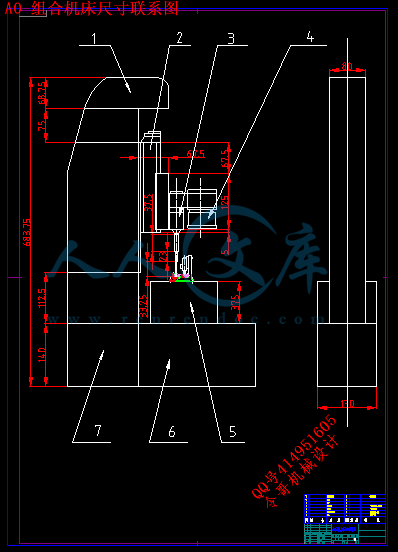

6.4 组合机床联系尺寸图的绘制…………………………………………………… 43

结束语………………………………………………………………………………… 44

致谢…………………………………………………………………………………… 45

参考文献……………………………………………………………………………… 46

附图 1 转速器盘零件图

附图 2 转速器盘加工工艺过程综合卡

附图 3 转速器盘加工工艺各工序工序卡

附图 4 夹具装配图

附图 5 被加工零件工序图

附图 6 被加工零件加工示意图

附图 7 组合机床联系尺寸

工艺规程是工装设计、制造和确定零件加工方法与加工路线的主要依据,它对组织生产、保证产品质量、提高劳动生产率、降低成本、缩短生产周期及改善劳动条件等都有着直接的影响,因此是生产中的关键工作。夹具在机械加工中起着重要的作用,它直接影响着机械加工的质量,生产效率和成本,因此,夹具设计是机械工艺准备和施工中的一项重要工作。本文对机转速器盘的结构和工艺进行了分析,确定了机械加工工艺路线,制订出了零件的铸造工艺方案和机械加工工艺规程,并为加工零件上直径mm的孔设计了一套专用钻床夹具和专用组合机床。

关键词 加工工艺 铸造工艺 工艺规程 夹具设计

毕业设计说明书(论文)外文摘要

Abstract

The process is the base of frock design、manufacturing、the method of machining and machining route. Its function is flowing: organizing produce, controlling quality, enhancing productivity, reducing cost, reducing produce periods, improving work conditions, etc. So, the process planning is the core part of produce. Fixture is very important equipment in process of machine manufacturing because it can directly affect the quality of products and productivity and cost. So fixture designing is also a basilica portion in machine process preparative and manufacture. This thesis is about the analysis with the craftwork and the structure of the speed governor tray , make sure the process route, establish the foundry process project and the process planning of the parts, and design a set of appropriative fixture for the bore with diameter 10mm.

Keywords Group technology Foundry technology Process planning Fixture design

1 引 言

毕业设计是在我们学完了大学的全部基础课、技术基础课以及全部专业课之后进行的。这是我们对所学各课程的一次深入的综合性的总复习,也是我们在走进社会工作岗位前的一次理论联系实际的训练。因此,它在我们四年的大学生活中占有重要的地位。就我个人而言,我希望能通过这次毕业设计对自己未来将从事的工作进行一次适应性训练,从中锻炼自己分析问题,解决问题的能力,为今后参加祖国的“四化”建设打下一个良好的基础。

本毕业设计的内容是制订转速器盘加工工艺及关键工序工装设计。详细讨论转速器盘从毛坯到成品的机械加工工艺过程,分析总结转速器盘的结构特点、主要加工表面,并制定相应的机械加工工艺规程;针对转速器盘零件的主要技术要求,设计钻孔用的钻床夹具和组合机床。

本着力求与生产实际相结合的指导思想,本次毕业设计达到了综合运用基本理论知识,解决实际生产问题的目的。由于个人能力所限、实践经验少、资料缺乏,设计尚有许多不足之处,恳请各位老师给予指教。

川公网安备: 51019002004831号

川公网安备: 51019002004831号