1.机床的类型及主要参数:C6132车床,变电动机功率:N=3Kw;最大转速=1120r/min、最小转速=25r/min;工作时间:一班制;变速级数:z=12。

2.工件材料:45号钢

3.设计部件名称:主轴箱

摘要

机床是用金属毛坯加工成机器零件的机器,它是制造机器的机器。他可一将金属毛坯技工成具有较高精度的形状、尺寸和较高表面质量的零件。他所担负的工作量占机器总制造工作量的40%-60%。机床的技术水平直接影响机械制造工业的产品质量和劳动生产率。机床的属性决定了它在国民经济中的重要地位。机床工业为各种类型的机械制造厂提供先进的制造技术与幼稚高效的机床设备,促进机械制造工业的生产能力和工艺水平的提高。机械制造业工业肩负着为国民经济各部门提供现代化技术装备的任务,即为工业、农业、交通运输业、科研和国防等部门提供各种机器、仪器和工具。为适应现代化建设的需要,必须大力发展机械制造工业。机械制造工业是国民经济各部门赖以发展的基础。机床工业则是机械制造工业的基础。一个国家机床工业的技术水平,在很大程度上标志着这个国家的工业生产能力和科学技术水平。显然,机床在国民经济现代化建设中起着重大的作用。

近些年来,随着电子技术、计算机技术、信息技术以及激光技术等的发展并应用于机床领域,使机床的发展进入了一个新时代。自动化、精密化、高效化和多样化成为为这一时代机床发展的特征,用以满足社会生产多种多样越来越高的要求,推动社会生产力的发展。新技术的迅猛发展和客观需求的多样化,决定了机床必须多品种;技术的加速更新和生产更新换代的加速。使机床主要面对多品种的中小批生产。因此现代机床不仅要保证加工精度、效率和高度自动化,还必须有一定的柔性,即灵活性,使之能够很方便地适应加工任务的改变。

20世纪以来,齿轮变速箱的出现,使机床的结构和性能发生呢感了根本性的变化。随着电气、液压等科学技术的出现并在机床上得到广泛应用,使机床技术有了迅速的发展。除通用机床外,又出现了许多边型品种和各式各样的专用机床。在机床发展的这个阶段机床的动力已由自然力代替了人力。特别是工业革命以来,人只需要操纵机床。生产力已不受人的体力的限制。我国的机床工业是在新中国成立后建立起来的,发展很迅速。现在,我国机床工业已经取得了很大的成就,但与世界先进水平相比,还有叫大的差距。主要表现在:大部分高精度和超精度机床的性能还不能满足要求,精度保持性也较差,特别是高效自动化和数控化机床的产量、技术水平和质量等方面都明显落后。因此,在我国机床工业面临着光荣而艰巨的任务,必须奋发图强,努力工作,不断扩大技术队伍和提高人员的技术素质,学习和引进国外的先进科学技术,大力开展科学研究,以早日赶上世界先进水平。

车床类机床主要用来加工各种回转表面。由于多种机器零件具有回转表面,车床的通用性又较广,因此在机器制造厂中,车床的应用极为广泛,在车床中所占的比重最大,约占机床总台数的20%-35%。

主轴箱是车床的重要组成部分,固定在床身的左端,内部装有主轴和变速及传动机构。工件通过卡盘等夹具装夹在主轴前端。它的主要任务是将主电机传来的旋转运动经过一系列的变速机构使主轴得到所需的正反两种转向的不同转速,同时主轴箱分出部分动力将运动传给进给箱。主轴箱中等主轴是车床的关键零件。主轴在轴承上运转的平稳性直接影响工件的加工质量,一旦主轴的旋转精度降低,则机床的使用价值就会降低。

设计中综合了应用机械设计、机床、工装等机械设计、制造系统理论知识与实践技能,适当结合CAD/CAM相关知识与技术,以质量、生产率和经济性辨证统一为原则,设计主要用于加工回转零件的车床主轴箱传动、结构及主要零件的设计。

设计中最主要讲述了普通中型车床主轴箱的结构设计,有车床的规格、参数,电动机的选择,动力设计和传动设计,轴和齿轮的确定,重要齿轮的设计齿轮机械加工工艺过程反感的确定等。另外为了更直观的看到整个设计,还有主轴箱的展开图、齿轮零件图。

关键词:普通中型车床 主轴箱 齿轮

Abstract

The machine is used for rough machining of metal machine parts into the machine, it is the machinery manufacturing machines. He will be a rough metal craftsmen with high precision into the shape, size and high surface quality of parts. He accounts for the work undertaken by the machinery manufacturing workload of 40% -60%. Machine direct impact on the technological level of manufacturing industrial machinery product quality and labor productivity. Machine attributes its decision in the important position of the national economy. Machine tool industry for various types of machinery factory in providing advanced manufacturing technology and naive efficient machine equipment, machinery manufacturing industries to promote the productive capacity and raise the level of technology. Machinery manufacturing industry is shouldering the national economy for the provision of modern technology and equipment department of the task, namely, industry, agriculture, transport, scientific research and national defense and other departments to provide all kinds of machinery, equipment and tools. In order to meet the needs of modernization, we must vigorously develop the machinery manufacturing industry. Machinery manufacturing industry is the sector's national economic development. Machine Tool Industry Machinery Manufacturing industry is the foundation. A country's machine tool industry technical standards, in large measure, marked the country's industrial production capacity and scientific and technological level. Clearly, the machine tool in the modernization of the national economy plays an important role.

In recent years, as electronic technology, computer technology, information technology, and laser technology used in machine tools and the development of the area so that the machine entered a new era. Automation and sophisticated, efficient and diversified into the era of machine tools for the development of the characteristics of a variety of social production to meet growing demands, and promote the development of productive forces. The rapid development of new technology and the diversification of an objective demand, the machine must be decided more variety; technologies to accelerate the updating and upgrading of production accelerated. Machine tools to face the main variety of small and medium-sized batch production. So modern machine tools not only to ensure that the processing accuracy, efficiency and a high degree of automation, must also have a certain flexibility, that is flexibility, so that it can easily adapt to changes in processing tasks.

Since the 20th century, the emergence of transmission gear, so that the structure and performance of machine tools in this sense a fundamental change. With electrical, hydraulic, and other science and technology and the emergence of widely used on the machine so that the machine tool technology has developed rapidly. In addition to general machine tools, and there are many varieties and the edge of a wide range of special machine tools. In this stage of the development of machine tools machine has been the driving force to replace the natural forces of human. Especially since the Industrial Revolution, people only need to control machine tools. Productivity out of people's physical limitations. China's machine tool industry is in the founding of new China, set up and develop very rapidly. Now, China's machine tool industry has made great achievements, compared with the advanced world level, there is big gap. The main problems: the majority of high-precision and ultra-precision machine tools still can not meet the performance requirements, and also to maintain the accuracy poor, especially the efficient automation and the output of CNC machine tools, technical standards and quality, obviously lagging behind. Therefore, in China's machine tool industry faces a glorious and arduous task, we must work hard, and growing technical team of technical staff and improve the quality of learning and the introduction of foreign advanced science and technology and vigorously carry out scientific research in order to catch up with the world at an early date Advanced level.

Lathe machine type mainly used for processing various rotary surface. A variety of machine parts with rotating surface, the universal lathe and a wider, so the machine factory in the application of a wide range of lathes, in the lathe had the largest share, accounting for about Taiwan's machine tool total number of 20% -35% .

Headstock lathe is an important part of the fixed bed in the extreme left, and loaded with spindle speed and transmission mechanism. Chuck, and so on through the workpiece clamping fixture in the front spindle. Its main task is to be the main motor came after a series of rotating the spindle speed to get the necessary institutions of both the pros and cons to the different speed and separation of the main driving force for me to pass into the campaign to me. Headstock middle-spindle lathes is the key parts. Spindle in bearings on the smooth functioning of a direct impact on the quality of the workpiece processing, once the rotating spindle to reduce accuracy, the machine will reduce the value.

The design of the application of integrated mechanical design, machine tools, cutting tools, technology, tooling and other mechanical design, manufacturing systems theoretical knowledge and practical skills, the right combination of CAD / CAM-related knowledge and technology, quality, productivity and economy of the principle of dialectical unity, Designed mainly for processing parts of the rotary lathe spindle box transmission, structure and major parts of the craft.

Design of the ordinary about the most important medium-spindle lathes me the structural design, lathe specifications, parameters, the choice of motors, power transmission design and design of a shaft and gear identification, the design of important gear, there is a large part of the design process Tooling and design, including gear machining process offensive determine the process and the process of developing the card, the fixture design. In addition to the more intuitive to see the whole design, the spindle box started map, spindle box profiles, gear parts and components in Figure fixture assembly

Key words:ordinary medium-sized lathe

目录

第1章 绪论1

1.1主轴及其部件设计的主要意义1

1.2 主要设计内容1

1.3主要技术参数1

第2章 车床主传动系统方案设计2

2.1 主传动的组成及要求2

2.1.1 主传动的组成2

2.1.2 主传动的设计要求2

2.2 主传动系统的传动方式3

2.2.1 集中传动式3

2.2.2 分离传动式3

2.3 主传动的变速方式3

2.3.1 变换齿轮变速3

2.3.2 滑移齿轮变速4

2.3.3 多速电动机变速4

2.3.4 各种变速机构的组合4

第3章 主传动系统的运动设计5

3.1 确定极限转速5

3.2 确定公比5

3.3 确定结构网和结构式5

3.3.1 传动组和传动副数的确定5

3.3.2 结构网和结构式各种方案的选择5

3.4 绘制转速图7

3.4.1 选定电动机7

3.4.2 拟定转速图的步骤7

3.5 齿轮齿数的确定9

3.5.1 传动组a10

3.5.2 传动组b10

3.5.3 传动组c10

3.5.4 换向齿轮副11

3.6 传动系统图的拟定11

第4章 主运动部件结构设计13

4.1 带传动设计13

4.1.1 确定计算功率13

4.1.2 选取V带型13

4.1.3 验算带速和确定带轮直径13

4.1.4 确定带传动的中心距和带的基准长度14

4.1.5 验算小带轮的包角14

4.1.6 确定带的根数14

4.1.7 计算单根V带初拉力的最小值15

4.1.8 计算压轴力15

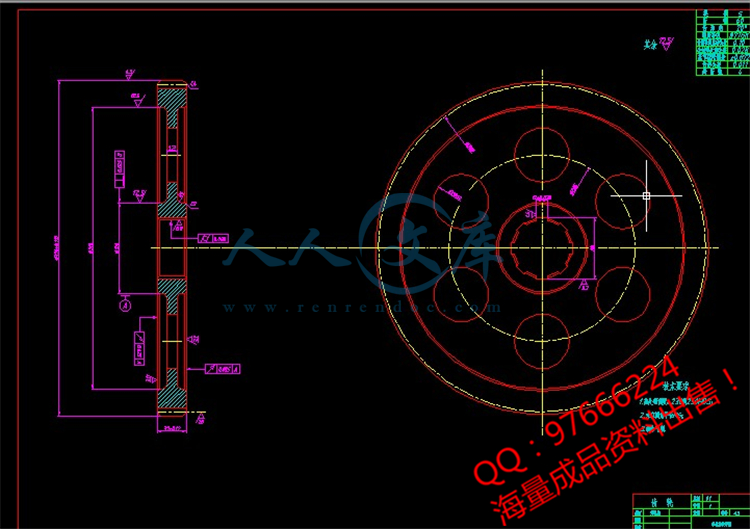

4.1.9 带轮的结构15

4.2 确定计算转速16

4.2.1 主轴16

4.2.2 各传动轴16

4.2.3 各齿轮16

4.2.4 核算主轴转速误差16

4.3 各传动组齿轮模数的确定16

4.3.1 传动组a17

4.3.2 传动组b17

4.3.3 传动组c18

4.4 齿轮尺寸表18

4.6 确定各轴最小直径23

4.6.1 Ⅰ轴的直径23

4.6.2 Ⅱ轴的直径24

4.6.3 Ⅲ轴的直径24

4.6.4 主轴的直径24

4.7 主轴组件设计24

4.7.1 主轴直径的初选24

4.7.2 主轴组件的前悬伸和跨距24

4.7.3 主轴组件最佳跨距选择24

4.7.4 主轴组件的选择26

4.7.5 轴的强度校核26

4 轴的受力分析28

4.7.6 轴的刚度校核30

第五章 有关零件的分析33

5.1零件分析33

5.1.1齿轮结构特点33

5.1.2齿轮的技术要求33

5.2齿轮材料、毛坯与热处理34

5.2.1材料的选择34

5.2.2齿轮毛坯的制造34

5.2.3材料的热处理34

5.3.定位基准的选择35

5.3.1粗基准的选择35

5.4齿轮的结构设计36

第6章 主轴箱箱体计算39

结 论41

参考文献42

致 谢43

![GQ7WH_X]IC$MI_RMVV[3P$F.jpg](https://www.renrendoc.com/ueditor/net/upload/2015-07-04/51cbfab6-c22b-420a-b16b-8711cc88a83c.jpg)

![OS}S%(]42U][IRG[`4Q~NLM.jpg](https://www.renrendoc.com/ueditor/net/upload/2015-07-04/5b38eeaa-d62d-406f-ab73-7c12296999d4.jpg)

川公网安备: 51019002004831号

川公网安备: 51019002004831号