马铃薯切片机设计【优秀含10张CAD图纸+食品加工机械全套课程毕业设计】

【带任务书+开题报告+中期检查表+文献综述+外文翻译】【27页@正文10100字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

外文文献.doc

开题报告.doc

文献综述元伟.doc

期中检查表.doc

毕业设计任务书.doc

毕业设计说明书.doc

2刀盘A2.dwg

2机架A0.bak

2箱体A2.dwg

2装配图A0.bak

2装配图A0.dwg

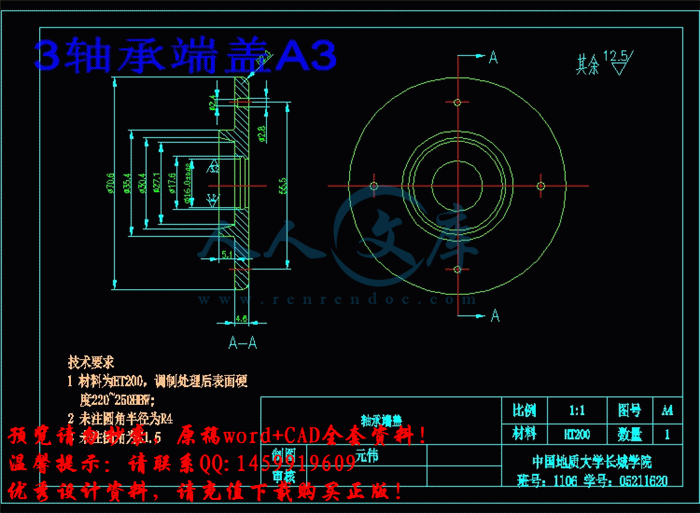

3轴承端盖A3.dwg

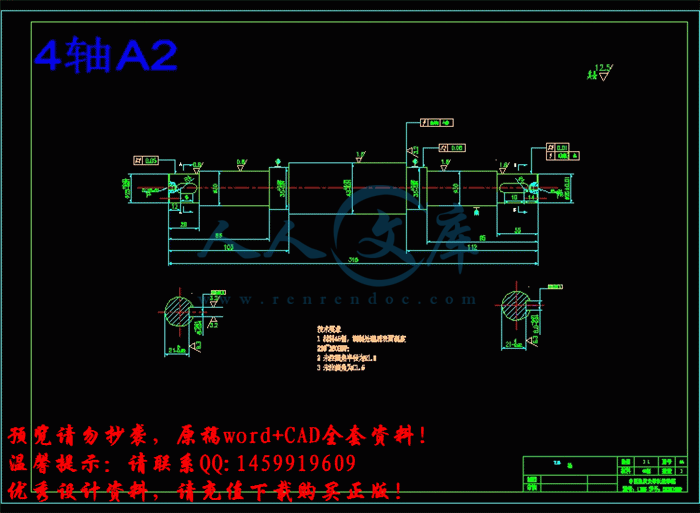

4轴A2.dwg

5大带轮A2.dwg

6小带轮A3.dwg

7轴上端盖A3.dwg

8轴下端盖A3.dwg

9固定箱盖A3.dwg

铃薯切片机设计

任务书

毕业设计(论文)题目马铃薯切片机设计

毕业设计(论文)主要内容和要求:

为了制作产品的需要,常常将马铃薯切成片状。加工对象为清洗干净的马铃薯,要求切成每片厚2~4mm的薄片,且厚度可调。采用电动机为动力,自动进料,生产力不小于500kg/h。要求进行整机结构设计、主要零部件的结构设计,要有工作能力的验算、传动系统的设计计算,写出设计计算说明书。

具体要求如下:

1、设计图纸不得少于3张(0#),全部用CAD绘制。

2、设计计算说明书不得少于1.0万字。正文的主要结构层次:

1)前言:主要写设计的目的、意义、研究的现状、本毕业设计的主要内容。

2)总体方案的拟定与计算:要有方案的比较、选优、必要的简图和设计计算,验证能达到上述设计目标。

3)关键零件的强度的计算与分析:如带轮、轴等,可以用计算机辅助设计计算,对设计的已知条件和结果可以用图形、表格等方式整理。

4)设计总结:是对整个毕业设计主要成果的总结。在总结中应明确指出本毕业设计的优点和缺点,对其应用前景和社会、经济价值等加以预测和评价,并指出今后进一步改进设计的方向与设想。

5)致谢:对老师和给予指导或协助完成毕业设计工作的组织和个人表示感谢。内容应简洁明了、实事求是。

毕业设计(论文)主要参考资料:

1.文献检索关键词:切片机 马铃薯 加工机械 食品机械

2.李良藻、汤楚宙主编. 农产品加工机械[M].长沙:湖南教育出版社,1989

3.杜连启.马铃薯食品加工技术. 金盾出版社.2007

4.崔大同主编. 果蔬加工机械[M].北京:北京农业大学出版社,1993.

5.中国农业机械化科学研究院.实用机械设计手册[M].北京.中国农业机械出版社.1984

6.刘鸿文. 材料力学[M]. 北京:高等教育出版社. 2011.1

7.许学勤.食品工厂机械与设备[M]. 北京.中国轻工业出版社.2008.138-142

8.沈再春.农产品加工机械与设备[M].北京.中国轻工业出版社.1993. 105-120

毕业设计(论文)应完成的主要工作:

1.任务书

2.开题报告

3.文献综述,外文翻译

4.撰写初稿

5.马铃薯切片机的叶轮及其刀片的设计

6.撰写论文,完成毕业论文雏形

7.整体结构的设计,图纸的完善

8.确定终稿

毕业设计(论文)进度安排:

序号毕业设计(论文)各阶段内容时间安排备注

01对所设计的题目内容进行了解2014年12月初

02资料的查阅、收集、整理,并撰写文献综述、开题报告、外文资料翻译2014年12月20日—2015年2月10日

03向指导老师汇报论文进展情况,将开题报告、文献综述交给指导老师审阅。经审阅合格后着手毕业论文的初稿撰写。2015年2月11日—2015年2月20日

04马铃薯切片机的机理研究,利用电子邮件等方式与指导教师沟通,修改计划和论文方案。2015年2月21日—2015年3月8日

05 马铃薯切片机的叶轮及其刀片的设计2015年3月9日—2015年3月31日

06撰写论文,完成毕业论文雏形,并定期向指导教师汇报进度,听取指导教师的意见和指导。2015年4月1日—2015年4月20日

07根据《中国地质大学长城学院毕业设计(论文)撰写规完成论文终稿撰写,整理相关表格资料。2015年4月21日—2015年4月30日

摘 要

马铃薯是一种常见的蔬菜,无论在家庭餐桌上还是在作坊里都是重要的食材。在日常生活中,马铃薯主要用于鲜食。在食品加工中,主要被加工成粉皮,淀粉和一些垃圾食品等。随着人们生活水平的提高,对生活质量有了更高要求,近些年来快餐业迅速发展,随之出现的马铃薯薯片、薯条等休闲食品消费量急剧增长,展现出强劲的势头。与此同时也促进了马铃薯的生产业和加工业的发展。而在马铃薯的多种工业加工过程中,时常需要将马铃薯进行快速处理并且加工量大,这样由人工来完成的话不仅效率低而且工作劳动量大,因此我们设计了一款马铃薯切片机。

本文设计的马铃薯切片机主要用于食堂、作坊及小型工厂等,它不仅可以对马铃薯进行加工还能够对洋葱和红薯等进行加工,还可以进行切丝处理。本设计主要任务是电动机选择,传动装置的设计,刀盘及刀片的设计,箱体的设计及重要零部件的校核计算等。本设计切片机有较高的效率,能对马铃薯、红薯进行工作。

关键词:切片; 切片机; 刀片;

Abstract

The?potato?is?a?kind?of?common?vegetable,?whether?in?the?family?dinner?table?or?factories?are?important?ingredients.?In?daily?life,?the?potato?is?mainly?used?for?table;?In?processing?factory,?the?potato?is?mainly?through?all?kinds?of?processing?technology?were?processed?into?fans,?and?vermicelli,?starch,?etc.,?and?part?of?machining?became?familiar?junk?food?(potato?chips,?French?fries).?With?the?improvement?of?living?standards,?have?a?higher?request?for?the?quality?of?life,?the?fast?food?industry?rapid?development?in?recent?years,?the?resulting?potato?chips,?French?fries?and?other?recreational?food?consumption?growing?rapidly,?showing?a?strong?momentum.?At?the?same?time?also?promote?the?development?of?potato?production?and?processing?industry.?In?the?potato?variety?of?industrial?processes,?often?needs?to?be?a?quick?potato?slices?processing,?to?finish?a?lot?of?potato?slices?in?a?short?time,?task,?artificial?is?difficult?to?complete,?which?makes?us?have?to?find?other?efficient?path?to?complete?these?tasks.?

This?article?in?view?of?the?above?questions?involving?a?is?mainly?used?in?the?dining?room,?restaurant,?shops,?and?home?the?potato?slicing?machine,?which?is?more?important?meaning?to?the?hotel,?its?produce?is?a?boon?for?restaurants?and?hotels.?It?is?worth?mentioning?that?this?design?not?only?can?the?potatoes,?sweet?potatoes?and?Onions?for?quick?slice,?shred.?This?article?investigated?zone,?shaft,?cutter,?blade,?such?as?the?design?and?calculation,?such?as?bearing,?key?components?for?choice.?This?design?slicer?have?higher?efficiency?and?can?work?on?potatoes,?sweet?potatoes.?The?advantages?of?this?design?mainly?has?the?following?several?aspects:?a,?to?cutting?a?variety?of?crops,?such?as:?potatoes,?sweet?potatoes,?sliced?onion;?And?of?uniform?thickness.?Second,?reduces?the?labor intensity,?improve?work?efficiency.?Third,?this?design?is easy operation simple and? compact structure?.

Key words: slice; slicer; blade;

目 录

1 前言1

2 选题背景1

2.1 国外发展情况1

2.2 国内切片机技术的发展概况1

3 切片机总体方案的确定2

3.1 结构特点与工作原理2

3.2 机构的组成部分及特点3

3.2.1 电动机3

3.2.2 皮带传动装置3

3.2.3 轴3

4 电动机的选择3

5 V带传动的设计计算4

5.1 V带材料的选择4

5.2求计算功率PC4

5.3 选V带的型号4

5.4 求小带轮d1,大带轮d2 基准直径4

5.5 验算带速度v5

5.6 确定V带的中心距a和基准长度Ld5

5.7 验算小带轮上的包角α15

5.8 求V带的根数6

5.9 计算单根V带的初拉力F06

6 V带轮的结构设计7

6.1 V带轮材料的选择7

6.2 带轮的结构尺寸的设计7

6.2.1 带轮结构形式的设计7

6.2.2 带轮尺寸的设计7

7 轴的选择9

7.1 计算轴的最小直径9

7.2 轴的结构尺寸确定10

7.3 轴的校核10

7.4 按弯扭合成应力校核轴的强度11

8 轴承的选择与校核12

8.1 轴承的选择12

8.2 轴承的校核12

9 键的选择和校核13

9.1 选择键连接的类型和尺寸13

9.2 校核键连接的强度13

10 刀片的设计14

10.1刀片类型的选择14

10.2 刀盘的总体结构设计15

11 入料斗的设计16

12 机座和箱体的设计17

12.1 机架的设计要求17

12.2 机架的材料选用17

12.3 机架整体结构的设计18

13 机体整体结构的设计19

14 结论19

参考文献21

致 谢22

参考文献

[1] 濮良贵、纪明刚. 机械设计[M]. 北京:高等教育出版社第八版. 143-272

[2] 王与、王顺喜. 饲料粉碎机发展现状分析[J]. 北京:粮食与饲料工业2007,10

[3] 王昆、何小柏,汪信远.机械设计课程设计[M]. 北京:高等教育出版社1996年版 130-152

[4] 沈再春主编.农产品加工机械与设备[M].北京.中国农业出版社.1993. 75-82

[5] 李良藻、汤楚宙主编. 农产品加工机械[M].长沙:湖南教育出版社,1989

[6] 无锡轻工业学院 天津轻工业学院编著. 食品工厂机械与设备[M]. 北京: 北京轻工业出版社,1981.

[7] 崔大同主编. 果蔬加工机械[M].北京:北京农业大学出版社,1993.

[8] 历建国、赵涛.食品加工机械[M]. 成都. 四川科学技术出版社出版. 1984. 130-152

[9] 刘鸿文. 材料力学[M]. 北京:高等教育出版社. 2011.1

[10] 中国农业机械化科学研究院.实用机械设计手册[M].北京.中国农业机械出版社.1984

[11] 沈再春.农产品加工机械与设备[M].北京.中国轻工业出版社.1993. 105-120

[12] You Bum-Jae.Hwangbo Myung.etc.Development of a Home Service Robot IEEE

International Conference on Intelligent Robots and Systems.2003,3:2630~2635

[13] Toshininchi Illinova, Horsham Kinwra,Junichi shim and others A Transmission:290~291

川公网安备: 51019002004831号

川公网安备: 51019002004831号