!【详情如下】【优秀机械毕业设计全套word+CAD图纸】【需要咨询购买全套设计请加QQ97666224】.bat

PDF报告.pdf

内径百分表的传动设计任务书.doc

内径百分表的传动设计说明书.doc

外文翻译=汽车的转向控制=4300字符.doc

孟双龙中期检查表.doc

开题报告--内径百分表的传动设计.doc

文献综述--内径百分表的传动设计.doc

内径百分表.dwg

圆柱齿轮170×0.2.DWG

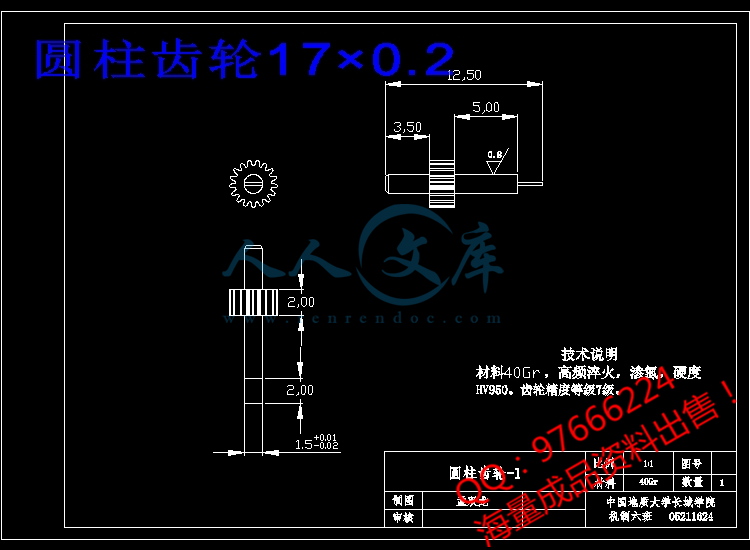

圆柱齿轮17×0.2.DWG

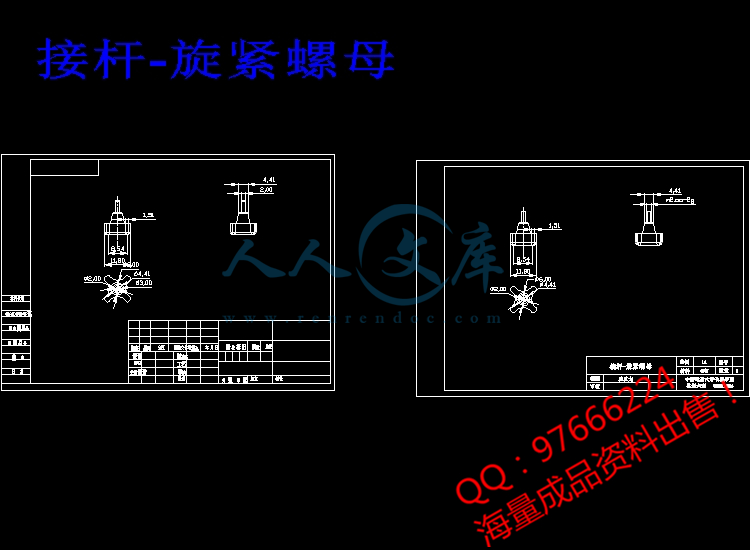

接杆-旋紧螺母.DWG

测量头-1.dwg

测量头-2.DWG

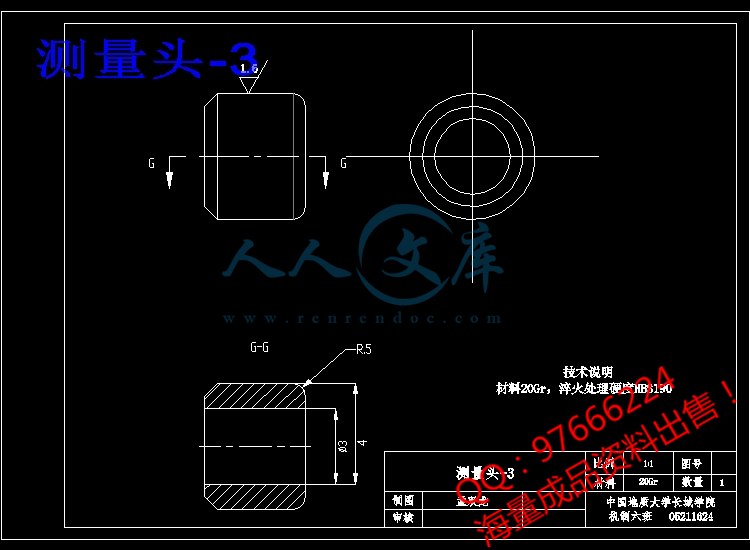

测量头-3.DWG

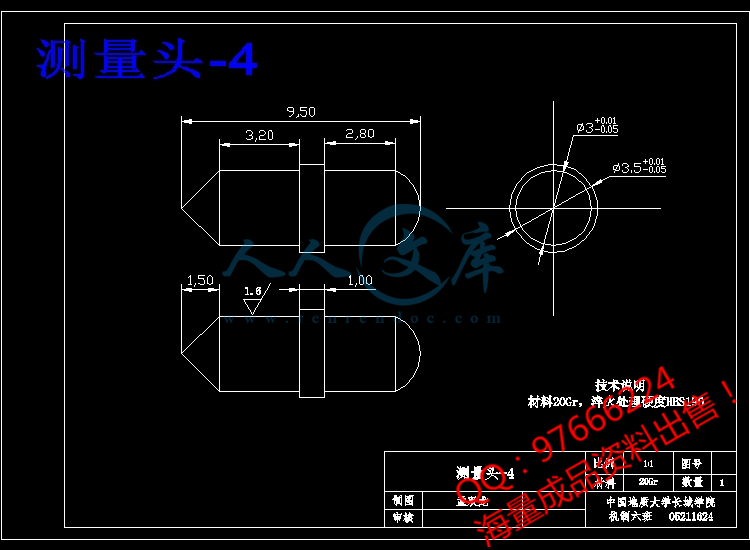

测量头-4.DWG

表座.DWG

齿条0.0106814150222053×0.2.DWG

摘 要

人们的生活水平提高了很多跟以往相比,对制造业的发展和设计有了新的认识和理解;后来社会上的人们对产品的精度和美观度要求越来越高,用于产品尺寸测量的测量工具不断得到发展,尤其是各种高效率、高精度的测量工具发展迅速。内径百分表是专门测量工件内径的重要测量工具,研究和分析内径百分表量具的动力设计和传动设计及计算方面具有划时代的积极影响。

本文通过对内径百分表的传动设计,确定了内径百分表的结构型式,完成了内径百分表的齿轮传动设计计算,确定了齿轮的模数、传动比等;确定内径百分表的尺寸及测量传动路线。完成了内径百分表的总体结构设计,绘制了完整的三维模型。本课题研究能为相应的精密测量仪器的设计提供参考。

关键词:内径百分表;齿轮传动;结构设计

ABSTRACT

People's living standards improved a lot compared to the past, the development of manufacturing and design a new understanding; Later people on society of the product precision and aesthetic demand is higher and higher measuring tool for measuring the sizes of product development, especially the high efficiency, high precision of measurement tool for rapid development. Bore dial indicator is an important special measurement of work piece diameter, drive design of bore dial indicator and has an important significance in calculation.

In this paper, through the design of bore dial indicator, to determine the structure of bore dial indicator, complete the calculation of gear drive design bore dial indicator, to determine the modulus gear, transmission ratio; determine the size and measurement of transmission line diameter dial indicator. The completion of the overall structure of bore dial indicator design, draw a complete 3D model. Research and analysis of inner diameter of the dial indicator measuring tool dynamic design and transmission design and calculation of epoch-making positive impact

Keywords: bore dial indicator; gear transmission; structure design

目 录

1 绪论2

1.1内径百分表发展现状2

1.2 内径百分表发展趋势4

1.2.1位移传感器(光栅、容栅、电感等)的数字式百分表4

1.2.2功能扩展型百分表5

2内径百分表的设计5

2.1内径百分表的总体结构设计5

2.2内径百分表的传动设计8

2.3模数及齿数的设计9

2.4游丝的设计12

2.5弹簧的设计14

3内径百分表其他零件的设计16

4 内径百分表的使用注意事项17

4.1内径百分表测量注意事项17

4.2内径百分表使用与保养17

4.2.1使用前检查17

4.2.2读数方法17

4.3 内径百分表故障及修理18

5 结论18

参考文献20

致 谢21

川公网安备: 51019002004831号

川公网安备: 51019002004831号