!【详情如下】【优秀机械毕业设计全套word+CAD图纸】【需要咨询购买全套设计请加QQ97666224】.bat

PDF报告.pdf

中期检查表.doc

任务书.doc

外文翻译.doc

开题报告.doc

文献综述.doc

说明书.doc

冲孔凸模.dwg

凹模.dwg

导料板.dwg

拨叉模具装配图.bak

拨叉模具装配图.dwg

排样图.dwg

落料凸模.dwg

装配图.dwg

零件图.dwg

摘 要

我国的模具行业与国外模具行业相比起步较晚,虽然近些年有了较快的发展,但是与国外的模具设计与制造业相比仍有一定的差距,这使得我国的模具寿命较低,产品的价格偏高。因而应该大力培养模具人才,努力缩小我国同发达国家之间的距离。

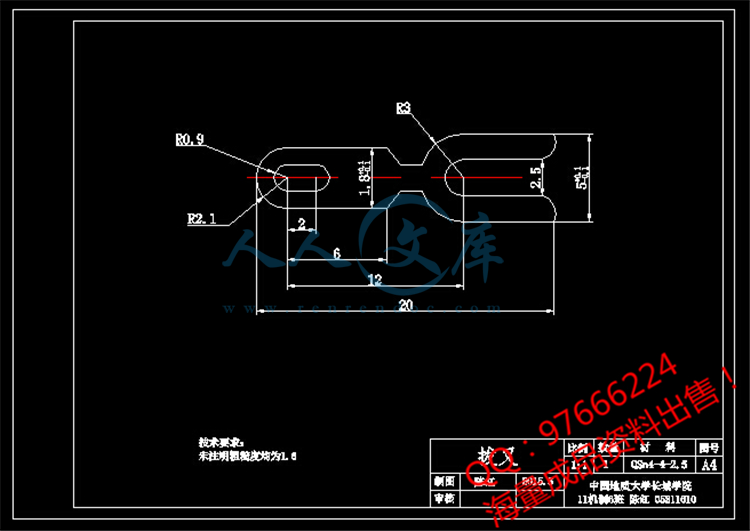

本次我所设计的是拨叉复合冲裁模,主要是想通过本次设计提高对模具课程的认知和理解,了解模具加工和设计过程中的重难点。对本次的加工零件进行分析,该零件所用的材料是锡青铜,生产批量是大批量生产,初步设定几个可行的加工方案并进行比较,选出其中比较合理的一个冲裁加工方案,本设计选择正装复合冲裁模;选出符合该模具的定位方式,卸料、出件跟导向方式;通过计算分析,最终完成该模具的主要设计计算;模具的凸、凹模的设计,选择模具的材料,确定每个零部件的加工方案。根据模具的装配原则,完成模具的装配。用装配好的模具进行试冲,找出模具设计和制造中的不足,发现原因并对模具做出适当的调整和修理。

关键词:模具 ;凸凹模 ;正装复合模

ABSTRACT

China's mold industry and the mold industry abroad started late, although in recent years there have been rapid developments, but compared with the mold design and manufacturing abroad still have a gap, which mold lower life expectancy and product prices on the high side. Should therefore foster mold talents, efforts to narrow the distance between China and the developed countries. This what I design is a fork of the compound blanking die, mainly through the design improve the awareness and understanding of the mold course, knowledge of molding process and problems in the design process.

On this time of processing parts for analysis, the parts by with of material is tin bronze, production bulk is big production, preliminary set several feasible of processing program and for compared, elected which compared reasonable of a rushed CD processing program; elected meet the mold of positioning way, unloading material, and out pieces with oriented way; through calculation analysis, eventually completed the mold of main design calculation; mold of convex, and concave die of design, select mold of material, determines each parts of processing program. According to mold assembly principle, complete the mold Assembly. Assembled mold test, find out shortcomings in mold design and manufacturing, cause finding, and the mold to make proper adjustments and repairs.

Key words:die ; punch-die ; dress in compound blanking die

目 录

1 冲压件的工艺性分析与方案确定5

1.1冲压件工艺性分析5

1.2冲压工艺方案的确定6

2 零件主要设计计算8

2.1排样方案的确定及计算8

2.2冲压力的计算9

2.3压力中心的确定10

2.4工作零件刃口尺寸计算11

2.5卸料橡胶的设计表13

3 模具的总体设计14

3.1模具类型的选择14

3.2定位方式的选择14

3.3卸料﹑出件、导向方式的选择14

4拨叉复合冲裁模主要零部件设计15

4.1 落料凸模的设计15

4.2 冲孔凸模的设计16

4.3凹模的设计16

5 模具材料的选用及其它零部件的设计18

5.1 模具的技术要求18

5.2模具材料的选用及要求18

5.3定位零件的选择20

5.4导料板、卸料部件设计21

5.5模架及其他零部件的设计21

6 模具总装图及设备的选定22

6.1模具的工作过程22

6.2模具的特点及结构分析23

结论22

致 谢25

参考文献26

川公网安备: 51019002004831号

川公网安备: 51019002004831号