多用途小型钻铣床设计【优秀含10张CAD图纸+机械钻床全套课程毕业设计】

【带任务书+开题报告+中期检查表+文献综述+外文翻译】【25页@正文13100字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

中期检查表 .doc

图纸

外文翻译.wps

多用途小型钻铣床-开题报告.doc

多用途小型钻铣床设计任务书.doc

多用途小型钻铣床设计文献综述.wps

多用途小型钻铣床设计说明书.doc

检测报告.zip

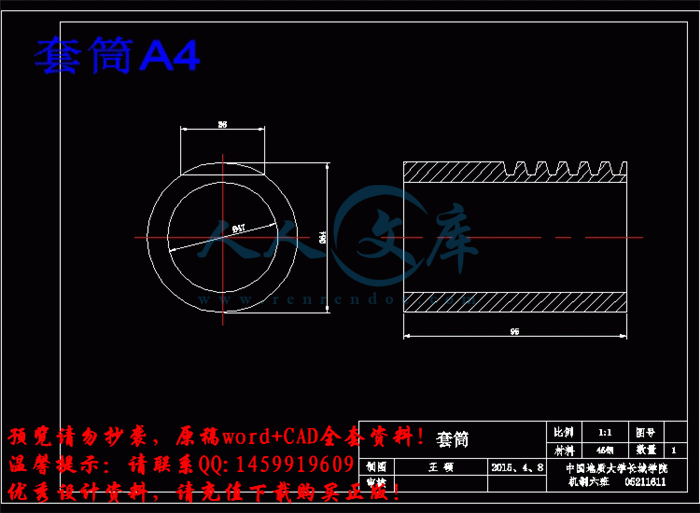

套筒A4.dwg

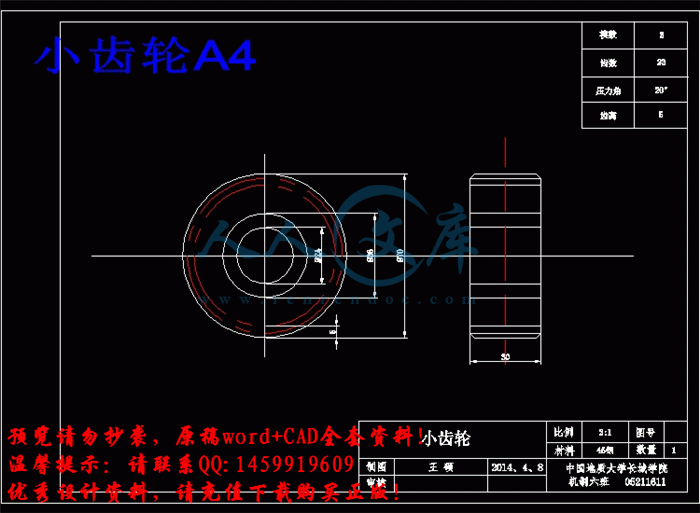

小齿轮A4.dwg

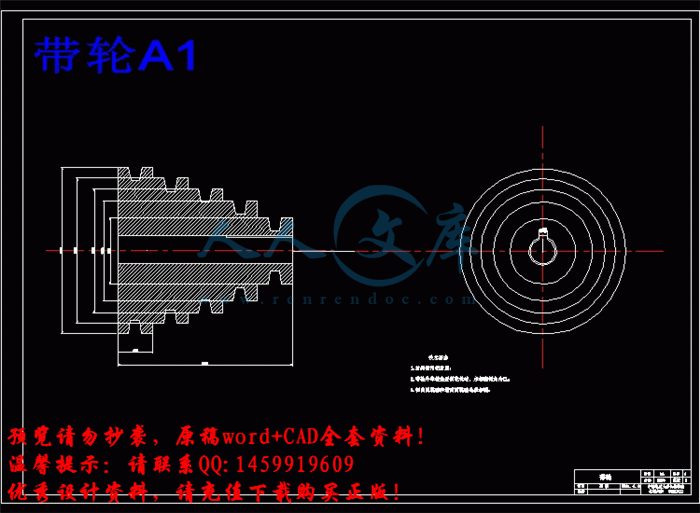

带轮A1.dwg

摇臂把手.dwg

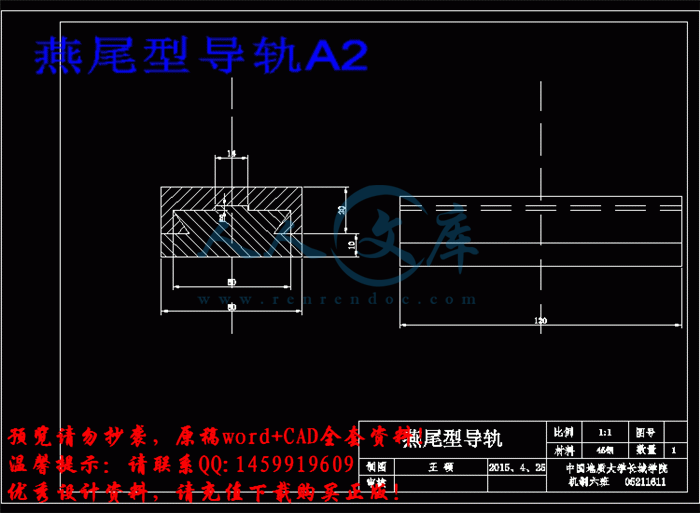

燕尾型导轨A2.dwg

立柱底座A1.dwg

螺钉.dwg

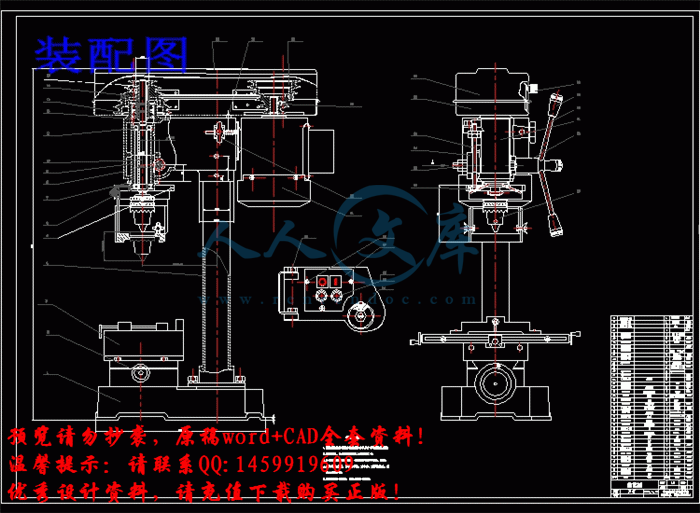

装配图.bak

装配图.dwg

轴A3.dwg

锁紧螺母.dwg

任务书

毕业设计(论文)题目

多用途小型钻铣床设计

毕业设计(论文)主要内容和要求:

主要内容:

设计多用途小型钻铣床

要求:

1. 调研相关产品,搜集相关资料。

2. 分析资料,拟定可行的设计方案。

3. 对比方案,确定最终方案。

4. 详细设计,绘制装配图,零件图,并撰写设计说明书。

毕业设计(论文)主要参考资料:

[1]濮良贵,纪名刚主编.机械设计.第4版.北京:高等教育出版社.

[2]郭克希,王建国.机械制图.第7版.北京:机械工业出版社,2006.8.

[3]左健民.液压与气压传动.第4版.北京:机械工业出版社,2007.5.

[4]王伯平主编.互换性与测量技术基础.第2版.北京:机械工业出版社,2008.12.

[5]刘鸿文主编.材料力学.第4版.北京:高等教育出版社,2004.

[6]于永泗,齐民.机械工程材料.大连:大连理工大学出版社,2007.2.

毕业设计(论文)应完成的主要工作:

1.查阅、收集资料,熟悉有关的资料,学习相关的知识。结合毕业设计课题进行外文资料阅读并翻译外文资料。

2.熟悉设计任务,提出初步的设计方案,并征求指导教师的意见。拟定总体方案,绘出系统图,定出相关参数,并绘出总体草图。

3.对草图进行修改,并完成开题报告。整理资料,编写设计说明书。

毕业设计(论文)进度安排:

序号毕业设计(论文)各阶段内容时间安排备注

1确定毕业设计题目,查阅并收集整理相关资料2014.12.15

2确定研究方法,分析处理数据,撰写论文大纲2015.01

3构思论文内容,设计开题报告,完成论文初稿的撰写2015.04.05

4论文修改润色,完成论文终稿,送交指导老师评审,进行答辩2015.04.05-2015.5

摘 要

本次设计的主题主要是通过对通用部件为基础的研究,在配上根据被需要加工的工件的特定的形状和特定的加工工艺,从而来确定的专用的部件等部分组成的专业型组合式机床。

多用途小型钻铣床主要由动力部分,底座部分,进给部分以及工作台部分组成,然后通过对原始数据的分析,对有关数据的计算,以及对设计方案的论证,完成对多用途小型钻铣床的总体设计。

通过目前我们学习到的机械只是和组合钻铣床的技术掌握。在目前科技允许的情况下,能够做到把小型钻床和铣床结合起来,做到工序集中,多工位同时运行加工的多用途小型钻铣床,使之具有设计制造周期短,劳动强度低,操作简单、安全低成本,高效率的优点,能够在大批量生产中得到广泛应用,从而可以组成一条完整的生产线,该机床可以适用于多种环境,可以具有能耗低,成本小,噪声小的特点。

关键词:多用途小型钻铣床; 组合机床; 高效率; 低成本

ABSTRACT

This design mainly studies the common components based on design process, and according to the specific shape and the workpiece in the line of sight, and determine the special professional tools and parts.

Multi purpose small milling is mainly composed of a power part, the base part, part material and the work table, and then through the analysis of the original data, the calculation of the relevant data, and it is proved that the design scheme, completed the overall design of multi-purpose small drilling and milling machine.

Through the grasp of our mechanical and combination of drilling milling technology. In the current technology allows it, can do small drilling and milling machine combined, the process of doing so, multiple operation processing at the same time, a small multi function drilling and milling machine, it has the design and manufacturing cycle is short, low labor intensity, simple operation, safety, low cost, high efficiency, and can be widely used in mass production, and can form a complete production line, the machine can be used in various environments, the advantages of low energy consumption, can have low cost, low noise characteristics.

Key words:Versatile small milling machine; combination machine; high efficiency; low cost.

目 录

1、绪论1

1.1 多用途小型钻铣床的加工产业现状和发展态势1

2、多用途小型钻铣床的组成、特点及设计2

2.1 多用途小型钻铣机床的分类及基本配置型式2

2.2 多用途小型钻铣床的组成以及特点3

2.3 多用途小型钻铣床的总体结构方案设计4

2.4 小型钻铣组合式机床的设计方法4

2.5 小型钻铣床和其他组合式机床的工艺范围及加工精度5

3、动力系统的设计6

3.1主轴箱的设计6

3.1.1主轴箱的主要简介6

3.2主轴箱的设计7

3.2.1电动机选取7

3.2.2转速初定7

3.2.3带轮计算7

4、机械系统设计10

4.1 参数计算10

4.1.1 切削力10

4.1.2 切削功率的计算11

4.2 工作台外形概述以及尺寸和对重量估算13

4.2.1 机床基础作用13

4.2.2机床类型14

4.3机床导轨14

4.3.1 X方向工作台尺寸确定15

4.3.2 Y方向工作台尺寸的确定15

4.3.3 重量估算15

4.4 滚动导轨参数确定16

总 结20

参考文献21

致 谢22

1、绪论

1.1多用途小型钻铣床的加工产业现状和发展态势

顾名思义,多用途小型钻铣床的意思就是把小型钻床和小型铣床结合起来,是组合机床能够把钻孔、铣平面和铣键槽的一些特种加工方法组合起来加工工件,从而获得所要求零件的几何形状、尺寸精度和表面质量。机床的作业主要是用来加工一些机器部件的设备。在一般普通的机械零件的制造中,组合式机床的使用大概占机械加工行业中所有技术加工装备的总台数的60%—80% 。钻铣床是一种同时具备钻床和铣床两种功能的综合型组合式铣床,其设计原理主要是根据钻床的主要特点来设计的,除了可以实现钻孔扩孔、铰孔外,还具有铣床的铣削和镗削等多项作用。它主要是由电动机、底盘、滑套、导向套、工作台(支撑工件)、丝锥固定套、皮带轮、轴承套等结合零件组成。

我国是当今世界上机床产量最多的国家,其中包括山东滕州,辽宁沈阳,中国台湾,浙江杭州等地方,不同的生产产地所生产的机床都是不同的,即便是这样,我国生产的机床在国际市场的竞争中还是处于较低的水平;虽然在国内的市场也面临着严峻的形势,一个方面是国内市场对各类机床产品的使用都有严格的需求,而另外一方面则是国外的机床产品充斥国内市场,使国产的机床滞销积压。在90年代的,国外生产的机床在国内市场的占有率仅达到15%左右,但是到了95年代却已达到了77%,这种现象使我国小型式组合机床的自主发展受到了严重影响。

参考文献

[1]濮良贵,纪名刚主编.机械设计.第4版.北京:高等教育出版社.

[2]郭克希,王建国.机械制图.第7版.北京:机械工业出版社,2006.8.

[3]左健民.液压与气压传动.第4版.北京:机械工业出版社,2007.5.

[4]王伯平主编.互换性与测量技术基础.第2版.北京:机械工业出版社,2008.12.

[5]刘鸿文主编.材料力学.第4版.北京:高等教育出版社,2004.

[6]于永泗,齐民.机械工程材料.大连:大连理工大学出版社,2007.2.

[7] 李云主编.《机械制造及设备指导手册》[M]. 北京:机械工业出版社,1997.8

[8] 哈尔滨工业大学编.《机械制造工艺设计手册》[M].哈尔滨工业大学出版社,1981年5月

[9] 上海市金属技术协会编.《金属切削手册》[M].上海科学技术出版社,1994.4年

[10] 东北重型机械学院,洛阳工学院.第一汽车制造厂职工大学编写,《机床夹具设计手册》第

[11] IF TOMM International Micro mechanism Symposium [M]. Tokyo Institute of Thechnology.to-kyo.June 1-3.1993.

[12] Robert J.Schilling.Fundamentals of Robotics-Analysis and Control[M]. New Jersey: Prentice Hall.1990.

[13] B.D.Choat.Jips. Tools and Fixtures Design[M].The Institution of Production Engineers.1972.

川公网安备: 51019002004831号

川公网安备: 51019002004831号