ZH1105柴油机气缸体粗镗组合机床后主轴箱设计

摘 要:组合机床是由大量的通用部件和少量专用部件组成的工序集中的高效率专用机床。为了提高加工精度和生产效率,需要设计一台组合机床来改善柴油机气缸体的加工情况。本课题设计的是ZH1105柴油机气气缸体粗镗组合机床。用于加工被加工零件后主轴箱的孔,孔径为φ114.4±0.10,φ115±0.10,φ122.4±0.10;表面粗糙度均为Ra6.3。设计的重点是总体设计和后主轴箱设计两部分。总体设计包括制定工艺方案,确定机床配置型式、结构方案以及“三图一卡”的绘制。后主轴箱设计包括后主轴箱装配图,零件图,有关计算、校核等。机床采用单工位卧式组合机床。刀具对零件的加工为平行加工,动力部件采用卧式安装,品字型结构。采用机械滑台实现刀具进给,借助导套引导刀具实现精度稳定的加工。本组合机床效率高,成本低,加工精度高,操作使用方便,减轻了工人的劳动强度,提高了劳动生产率。

关键词:柴油机;气缸体;镗孔;组合机床;主轴箱

Design of ZH1105 Diesel Cylinder Body Thick Boring Modular Machine Collectivity and Back Headstock

Abstract: Modular Machine is composititved with a lot of currency parts and a small number of expert used parts focused on the working procedure of high efficiency dedicated machine. In order to prove the disposition and the production efficiency, we need to design a modular machine tool to improve the production of the diesel engine body. This topic is the design of ZH1105 diesel cylinder body thick boring modular machine. The modular machine tool is used to φ114.4±0.10,φ115±0.10,φ122.4±0.10 hole of back headstock, the surface roughness is Ra6.3. The focal point of this topic is the system design and the back headstock design. The system design including the definite of the modular machine tool, the selecting of the structure plan and the completing of the technological drawing of the part which need to be manufactured, the general drawing of modular machine tool, drawing of cutter display and the efficiency card of manufacture. The back headstock design including drawing the back headstock assemble, the box body complementarity process and accessory, bear on the calculation and checkout. The machine uses the horizontal-type single location modular machine. Tool used parallel processing on parts , and power components used horizontal installation, goods Text structure. Using mechanical sliding unit, with the aid of precisely leads the set of guidance cutting tool to complete dispositional process.This modular mechanical tool has such advantages,it is high efficiency, the cost is low, the processing precision is high, it is easy to operate, it reduces the worker’s labor intensity, and it enhanced the productivity.

Key word: Diesel, Cylinder body,Bore hole, Modular machine tool, Headstock

目 录

1前言1

2 组合机床总体方案论证3

2.1 组合机床工艺方案的制定3

2.1.1工艺路线的确立3

2.1.2机床的选择3

2.1.3定位基准的选择4

2.1.4滑台型式的选择4

2.2组合机床配置型式的选择4

2.2.1组合机床的配置型式4

2.2.2选择机床配置型式和结构方案的一些问题4

2.3 削用量及选择刀具5

2.3.1选择切削用量5

2.3.2计算切削力、切削扭矩及切削功率7

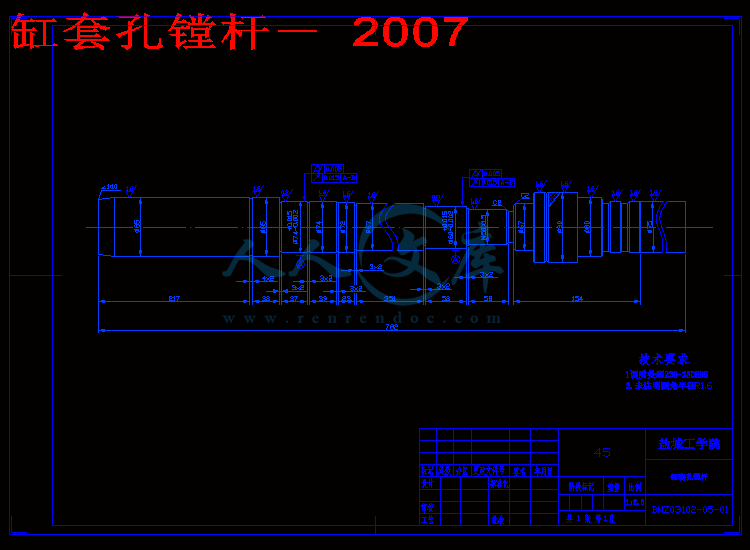

2.3.3选择刀具结构11

2.4 机床总体设计—三图一卡11

2.4.1被加工零件工序图11

2.4.2加工示意图12

2.4.3机床尺寸联系总图14

2.4.4机床生产率计算卡17

3.主轴箱设计19

3.1专用主轴箱设计19

3.2传动系统的设计.....................................................19

3.2.1电动机的选择.....................................................19

3.2.2电动机功率的选择.................................................19

3.2.3传动系统总传动比的确定及各级分传动比的分.........................19

3.3齿轮的设计及参数的确定.............................................20

3.3.1齿轮的设计.......................................................20

3.3.2齿轮参数的确定...................................................23

3.4轴承的选择.........................................................26

3.5主轴箱附件的说明...................................................27

3.5.1润滑及润滑元件...................................................27

3.5.2其他附件.........................................................27

4结 论..............................................................28

参考文献29

致 谢30

附 录31

1前言

组合机床是由大量的通用部件和少量专用部件组成的工序集中的高效率专用机床。它能够对一种(或几种)零件进行多刀、多轴、多面、多工位加工。在组合机床上可以完成钻孔、扩孔、铰孔、镗孔、攻丝、车削、铣削、磨削及滚压等工序,生产效率高,加工精度稳定。

组合机床具有如下特点:

a.要用于棱体类零件和杂件的孔面加工。

b.产率高。因为工序集中,可多面、多工位、多轴、多刀同时自动加工。

c.加工精度稳定。因为工序固定,可选用成熟的通用部件、精密夹具和自动工作循环来保证加工精度的一致性。

d.研制周期短,便于设计、制造和使用维护,成本低。因为通用化、系列化、标准化程度高,通用零部件占70%~90%,通用件可组织批量生产进行预制或外购。

e.自动化程度高,劳动强度低。

f.配置灵活。因为结构模块化、组合化。可按工件或工序要求,用大量通用部件和少量专用部件灵活组成各种类型的组合机床及自动线;机床易于改装;产品或工艺变化时,通用部件一般还可重复利用。

组合机床的设计,目前基本上有两种情况:其一,是根据具体加工对象的具体情况进行专门设计,这是当前最普遍的做法。其二,随着组合机床在我国机械行业的广泛使用,广大工人总结自己生产和使用组合机床的经验,发现组合机床不仅在其组成部件方面有共性,可设计成通用部件。而且一些行业的在完成一定工艺范围的组合机床是极其相似的,有可能设计为通用机床,这种机床称为“专能组合机床”。这种组合机床就不需要每次按具体加工对象进行专门设计和生产,而是可以设计成通用品种,组织成批生产,然后按被加工的零件的具体需要,配以简单的夹具及刀具,即可组成加工一定对象的高效率设备。

川公网安备: 51019002004831号

川公网安备: 51019002004831号