摘 要

数控机床即数字程序控制机床,是一种自动化机床,数控技术是数控机床研究的核心,是制造业实现自动化、网络化、柔性化、集成化的基础。随着制造技术的发展,现代数控机床借助现代设计技术、工序集约化和新的功能部件使机床的加工范围、动态性能、加工精度和可靠性有了极大的提高。

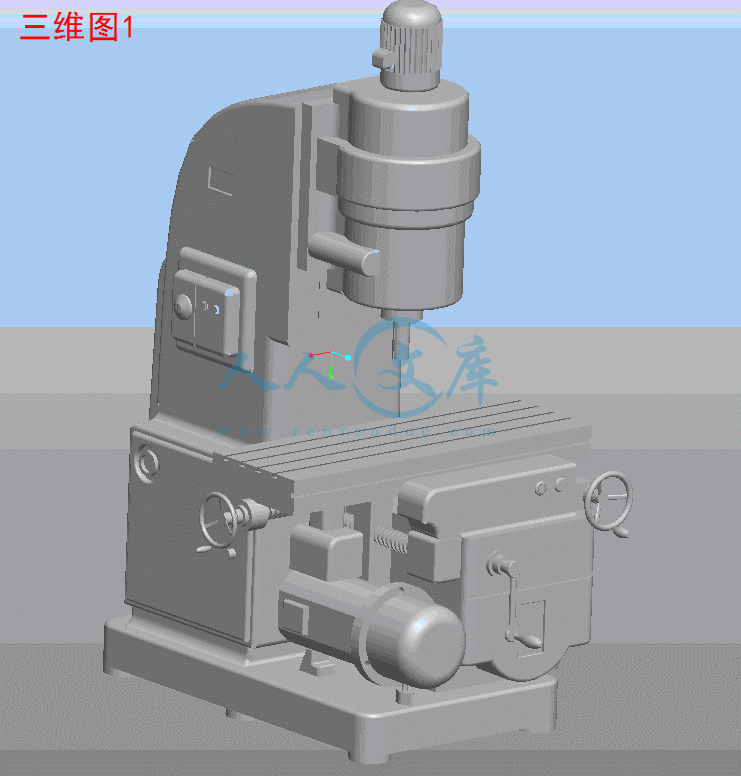

本次设计通过对现有数控钻铣床的分析研究,提出一种新的设计方案,其自动化程度更高,结构也相对比较简单。这一点在论文会得以体现。本方案中,主轴箱采用电磁离合器实现有级变速,在X、Y、Z三个方向上的进给运动均采用滚珠丝杆,而动力则由步进电动机通过调隙齿轮来传递,并且采用单片机进行数字控制。

控制系统采用MCS-51系列单片机,通过扩展程序存储器、数据存储器和I/O接口实现硬件电路的设计。论文中也对软件系统的设计做出了相关说明。

关键词:数控技术 滚珠丝杆 步进电机 单片机系统扩展

ABSTRACT

The numerical control engine bed is the digital process control engine bed, is one kind of automated engine bed, the numerical control technology is the core which the numerical control engine bed studies, is the manufacturing industry realization automation, the network, the flexibility, the integrated foundation. Along with the manufacture technology development, the modern numerical control engine bed with the aid of the modern design technology, the working procedure intensification and the new function part caused the engine bed the processing scope, the dynamic performance, the processing precision and the reliability had the enormous enhancement .

This design tries a new method after the analyze and research of the exited numerical control bed for mill and bore with the higher automatization degrees and the simpler configuration, which will be explained in the paper. In the method, electromagnetism clutch is used for the realization of the level shift in the headstock, and in the motion of , we all adopt ball bearing thread haulm for the X、Y、Z direction ,The power of which is step by step electromotor transferred by gear that used for adjusting gaps. And more, we used singlechip for numerical control.

The control system introduces MCS-51 series singlechip, and the realization of hardware circuit was accomplished by enlarging program memorizer、data memorizer and I/O meet meatus. Also, the paper explained the design for software system.

Keywords: Numerical control technology、Ball bearing thread haulm、

The step by step electromotor、The enlarge for SCM system

目 录

第1章 机床总体布局设计.......1

1.1机床总体尺寸参数的选定......1

1.2机床主要部件及其运动方式的选定........1

1.2.1 主运动的实现.....1

1.2.2 进给运动的实现.......1

1.2.3 数字控制的实现......1

1.2.4 机床其它零部件的选择......1

1.3机床总体布局的确定 ......2

第2章 主运动的设计........3

2.1议定转速图.........3

2.1.1确定结构式和结构网式...3

2.1.2拟定转速图.......4

2.1.3确定各齿轮的齿数...5

2.1.4传动系统图的拟定.......7

2.2主传动主要零件的强度计算...8

2.2.1电动机的选择.........8

2.2.2齿轮传动的设计计算...9

2.3轴的设计计算.....12

2.3.1各传动轴轴径的估算.....12

2.3.2各轴段长度值的确定.....14

2.3.3轴的刚度与强度校核.....14

2.4离合器的选用 ..........27

第3章 进给系统的设计计算 .27

3.1垂直进给系统的设计计算 ......27

3.1.1脉冲当量和传动比的确定....28

3.1.2滚珠丝杠设计计算.......29

3.1.3步进电机的选择.......33

3.1.4滚珠丝杆副的预紧方式...34

3.1.5齿轮传动消隙.......35

3.2横向进给系统的设计计算.....35

3.2.1脉冲当量和传动比的确定...35

3.2.2滚珠丝杠设计计算......37

3.2.3步进电机的选择.....38

第4章 控制系统的设计.....39

4.1控制系统总体方案的拟定.....39

4.2总控制系统硬件电路设计 ..40

4.2.1单片机的设计........40

4.2.2系统的扩展.......43

4.2.3键盘、显示器接口设计..48

4.2.4步进电机控制电路设计.....50

4.2.5光电隔离电路设计.....53

4.2.6其它接口电路的设计....54

4.3部分控制程序 .....54

4.3.1直线圆弧插补程序设计 ...54

4.3.2直线插补程序.......54

4.3.3圆弧插补程序设计.........55

4.4控制系统的软件设计..........59

4.4.1步进电机控制程序设计 ......59

4.4.2 LED动态显示接口程序设计.........61

结论 .................64

致谢 .........65

参考文献 ........66

科技译文..........

实习报告 ...........

川公网安备: 51019002004831号

川公网安备: 51019002004831号