摘 要

本课题是柴油机汽缸体两端面铣削专机设计,主要是完成机床夹具设计、组合机床总体设计、组合机床主轴箱设计。根据柴油机汽缸体的结构特点、加工部位、尺寸精度、表面粗糙度及生产率等要求,确定该机床为卧式组合机床;考虑工件尺寸精度,表面粗糙度,切削的排除生产率等因素,选用硬质合金不重磨式面铣刀;根据工件的尺寸、特点及其材料选择切削用量;然后,再经过切削用量来确定组合机床的通用部件;最后进行组合机床的总体设计。由于是铣削柴油机汽缸体的两端面,则夹具的设计可以采用“一面两销”定位,手动夹紧,一次装夹加工汽缸体两端面,保证加工精度,提高生产率;根据工作将受到切削力来计算夹紧力;再根据夹紧力来选择确定夹紧装置的专用部件。

在设计之中,尽量使用通用件,减少制造成本,增加经济效益。通过本次设计可以达到的效果是:所设计的夹具及主轴箱能满足所需的质量要求,使用时安全可靠,拆装方便,易于维修。

关键词:组合机床;汽缸体;铣刀;夹具

Abstract

This topic is called a diesel engine at both ends of the cylinder block face milling plane design, mainly including the completion of jigs and fixtures design, the combination of the overall machine design and machine tool spindle box design. According to the structural characteristics of the diesel engine cylinder block, the processing site, dimensional accuracy, surface roughness and productivity requirements, it can be determined that the machine is a horizontal combination of machine tools; considering the accuracy of the workpiece dimensions, surface roughness, cutting negative factors such as productivity, the hard-alloyed throw-away grinding-face milling is chosen; cutting amount is selected according to the size of the workpiece. characteristics and material selection; then, by the cutting amount we determine the combination of general machine parts; Finally, the overall design of the machine is carried out. Due to both end faces of the milling diesel engine cylinder block, the design of the fixture can employ "the two sells" positioning, manual clamping, a fixture worked both ends of the cylinder block surface to ensure accuracy and improve productivity; clamping forces will be calculated through the cutting force; and determine specific parts of the clamping device according to the clamping force.

In such a design, one should make use of common parts to reduce manufacturing costs and increase economic benefits. The design can achieve the effect that the design of the fixture and spindle box can meet the quality requirements and it guarantees safe and reliable use, easy disassembly and easy maintenance.

Key words: combination machine tools; The cylinder body; Milling cutter;fixture

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 课题来源1

1.2 国内外的发展状况1

1.3 指导思想和设计要求2

2 总体方案论证3

2.1 被加工零件分析3

2.2 工艺方案的制定3

2.3 加工设备方案选择3

2.4 确定机床总体布局4

3 切削用量的选择及计算5

3.1 切削刀具的选择5

3.2 切削用量的选择5

3.3 切削力、切削转矩、切削功率的确定5

4 组合机床总体设计8

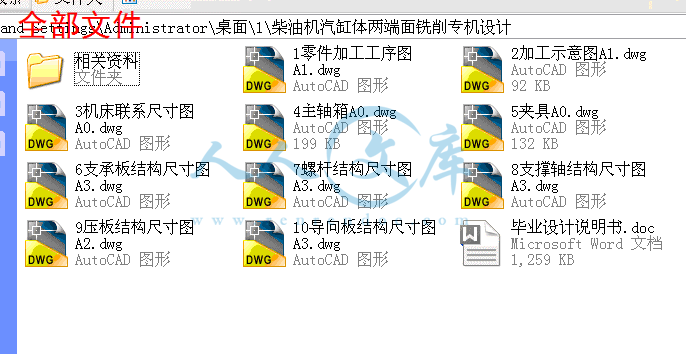

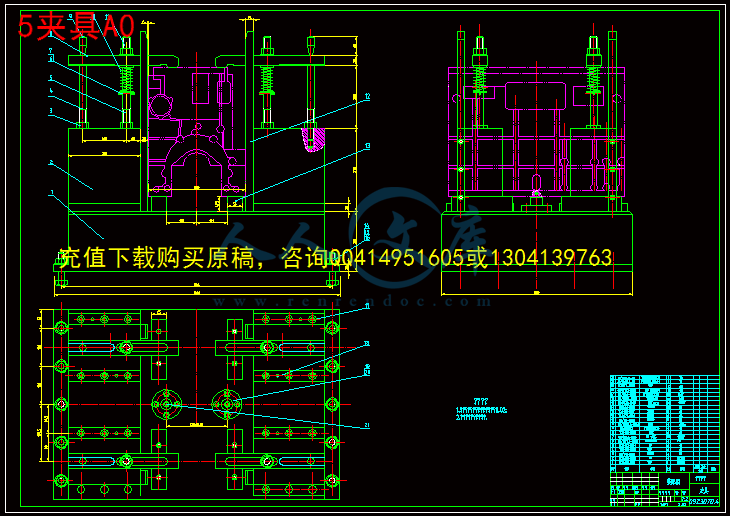

4.1 被加工零件工序图8

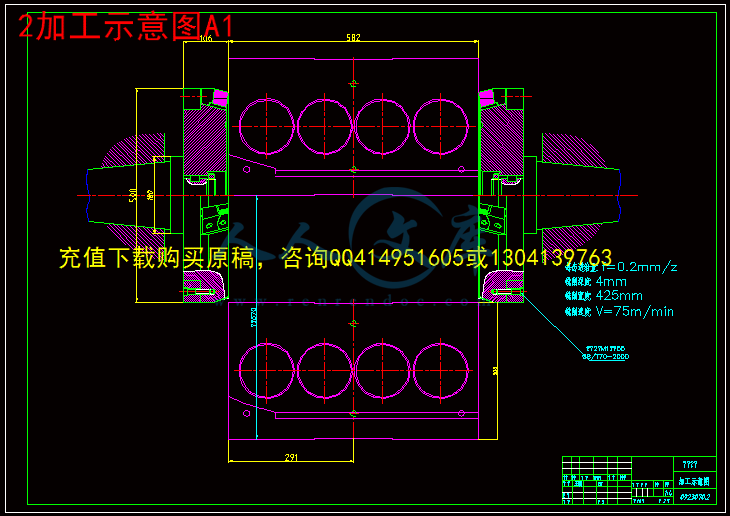

4.2 加工示意图9

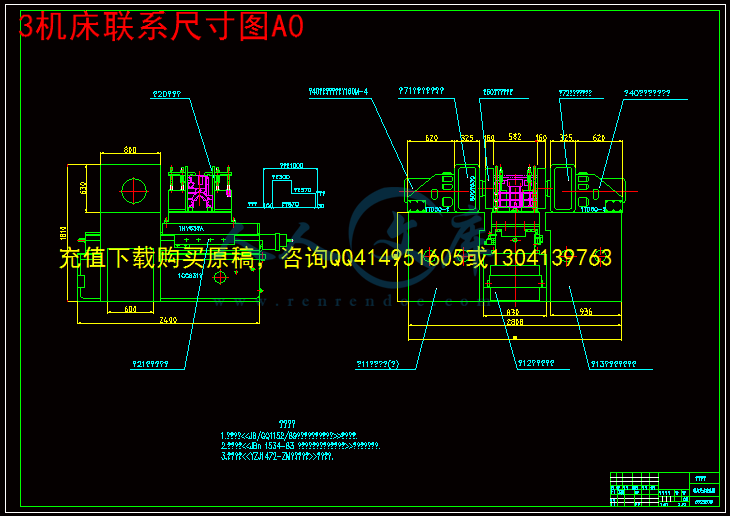

4.3 机床联系尺寸图10

4.3.1 动力部件的选择10

4.3.2 滑台及相配底座的选择11

4.3.3 确定机床的装料高度H11

4.4 机床生产率计算卡11

4.4.1 理想生产率Q11

4.4.2 实际生产率Q112

4.4.3 机床负荷率ŋ负13

4.4.4 编写机床生产率计算卡14

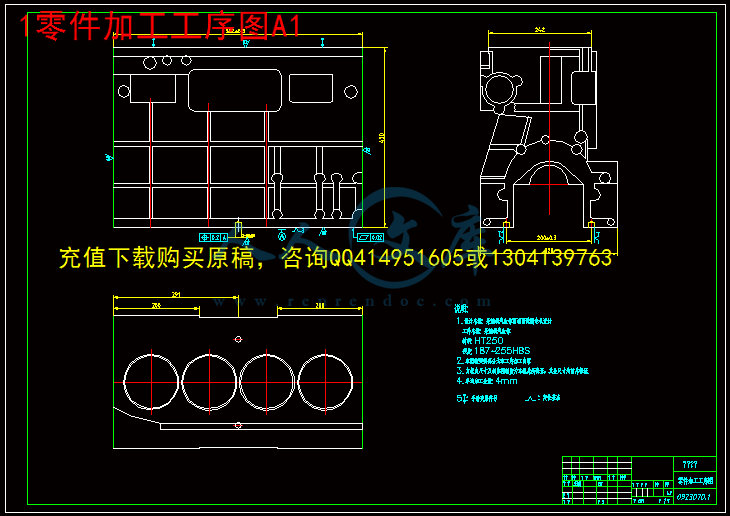

5 主轴箱设计15

5.1 主轴及传动轴结构设计15

5.2 主轴箱传动计算16

5.2.1 传动比分配16

5.2.2 传动系统设计及齿轮的排布17

5.3 主轴箱的润滑及油泵轴的确定18

5.4 轴的计算及主轴校核18

5.5 齿轮的校核20

5.6 轴承的选择与校核21

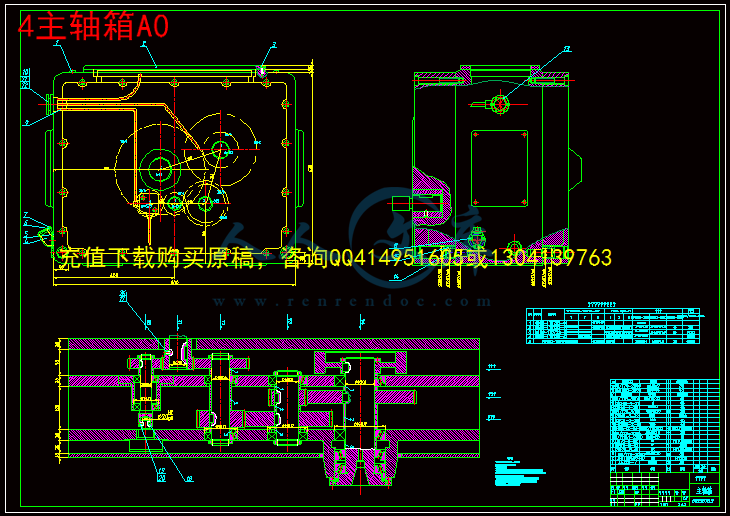

6 夹具设计24

6.1 定位误差分析计算24

6.2 夹紧装置设计25

6.3 夹紧力的计算25

6.4 夹具零部件的设计27

6.4.1 夹具体的设计27

6.4.2 支座的设计28

6.4.3 支承板的设计28

6.4.4 螺杆的设计29

6.4.5 支承轴的设计30

6.4.6 压板的设计30

6.4.7 导向板的设计31

7 液压系统设计32

7.1 负载分析32

7.2 负载图和速度图的绘制32

7.3 液压缸主要参数的确定32

7.4 拟定液压系统原理图35

7.4.1 液压系统的工作要求的确定35

7.4.2 拟定液压系统图35

7.5 计算和选择液压元件37

7.5.1 确定液压泵的最高工作压力37

7.5.2 确定液压泵流量38

7.5.3 选择液压泵规格38

7.5.4 计算油泵需要的电机功率38

7.6 阀类元件的选择38

7.7 油管的确定39

7.8 确定其它辅助装置39

7.9 发热及油箱容量计算39

8 结论与展望40

8.1 结论40

8.2 展望40

致 谢41

参考文献42

1 绪论

1.1 课题来源

随着工业生产规模化、专业化、集中化、高度机械化乃至自动化的步伐的加快,在进行工件加工时,要求考虑使用专用机床和夹具。组合机床和组合机床自动线是一种专用高效自动化技术装备,目前,由于它仍是大批量机械产品实现高效、高质量和经济性生产的关键装备,因而被广泛应用于汽车、拖拉机、内燃机和压缩机等许多工业生产领域。某企业因生产发展需要,拟开发柴油机汽缸体两端面铣削专机,因此选定柴油机汽缸体两端面铣削专机设计为本次设计课题

川公网安备: 51019002004831号

川公网安备: 51019002004831号