摘 要

专用组合机床目前是一种普遍的机械装置,应用于大批量生产领域,具有相当的柔性,加工精度高,生产效率提高,劳动强度减轻。

本文就是社会生产的实际需要提出的设计题目。根据现有的空气压缩机机身的相关资料,制定空气压缩机机身的加工工艺,组合铣机身三斜面的夹具设计、液压系统设计。在此基础上提出新的加工工艺和符合新工艺的加工专用机床方案,让改进和创新后的产品更适合工厂和顾客的需求。

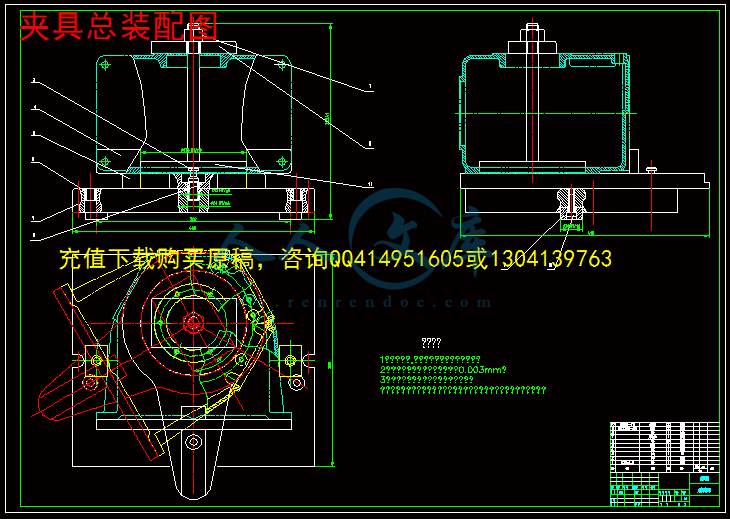

本文在对组合铣三斜面的工装设计过程中,对铣三个斜面及钻孔的专用夹具进行了全面的设计。从夹具的外型尺寸设计到具体的一面两销限制自由度定位方案再到加工面精度的计算:液压进给系统的设计,本文也用了不少的篇幅。重点根据液压系统的基本原理,画出合理的液压系统图;根据主要参数确定了液压元件的选择,在组合机床设计过程中结合具体实践和设计经验,阐述了通用件如(液压滑台)的选取及专用部件(如主轴箱)的设计计算。

最后希望此次设计的夹具和液压系统能达到预期的设计要求,并能在实际的应用中取得良好的效果。

关键词:组合机床;专用要求;工艺;钻夹具;液压

Abstract

Special combined machine tool is a mechanical device for universal, applicable to mass production, is quite flexible, high machining accuracy, improve production efficiency, reduce labor intensity.

This paper is the design requirement of social production. According to the relevant data of the existing air compressor machine, machining process air compressor airframe design, fixture design, combination milling body three inclined planes of the hydraulic system. On the basis of this new processing technology is proposed and in line with the new technology of special machine tool for processing scheme, make improvement and innovation of the products more suitable for factories and customer needs.

Based on the combination of the three bevel milling fixture design process, special fixture of milling three and inclined boreholes were comprehensive design. From the dimension design of fixture to the two side pin constrained degrees of freedom positioning scheme to the calculation of machining surface precision: the design of hydraulic feed system, this paper also use a lot of space. Key according to the basic principle of hydraulic system, draw the diagram of hydraulic system reasonable; according to the main parameters of hydraulic component has been selected, combined with the specific practice and experience in the design process in the design of the modular machine tool, describes the general parts (such as hydraulic slider) selection and special parts (such as the design and calculation of main spindle box).

Finally, I hope this design fixture and hydraulic system can meet the design requirements, and can achieve good effect in actual application.

Key words:unit built machine tool ;special requirements ;craftwork ;drill jig ;hydraulic pressure

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 力源压缩机有限公司简介1

1.2 本课题的意义目的1

1.3 本设计的技术要求1

2 压缩机机身铣三斜面加工工艺规程设计2

2.1工艺方案的制定2

2.2 产品图纸及结构分析2

2.3 毛坯分析、要求及形式的确定3

2.3.1 毛坯种类的选择3

2.3.2 选择毛坯应考虑的因素3

2.3.3 确定毛坯的制造形式4

2.4 拟定加工工艺路线4

2.4.1 定位基准的选择4

2.4.2 表面加工方法的选择5

2.4.3 加工顺序的安排5

2.5 加工余量、工序尺寸及其公差和毛坯尺寸的确定7

2.5.1 加工余量的拟定7

2.5.2 加工余量及毛坯尺寸的确定8

2.5.3 工序尺寸及其公差的确定9

2.6 加工工艺规程9

2.6.1 机械加工工艺规程的作用9

2.6.2 制定机械加工工艺的原则9

2.6.3 粗、精铣三斜面工序9

2.7工艺、主要工序卡片12

3 空压机机身铣三斜面专用机床总体设计概述17

3.1机床总体设计17

3.1.1 专用机床概述17

3.1.2 机床设计应满足的要求17

3.2 机床设计方法18

3.3 机床设计步骤19

3.4 机床对部件设计的要求20

3.5 加工零件图的设计21

3.5.1 被加工零件工序图的确定21

4 夹紧系统设计22

4.1 机床夹具概述22

4.1.1 工件装夹的实质22

4.1.2 机床夹具的功能22

4.1.3 机床夹具要点22

4.2 夹具设计的主要依据23

4.3 本工序夹具主要达到的目的23

4.4 定位方案及定位基准的选择23

4.4.1 工件的定位分析23

4.4.2 工件定位方案及定位基准的选择24

4.4.3 定位元件的选择24

4.5定位误差分析计算24

4.5.1定位误差产生的原因24

4.5.2定位误差的计算25

4.6夹紧方式及夹紧装置设计25

4.6.2 夹压方向及夹压点选择26

4.6.3 夹紧力的计算27

4.6.4 具体结构设计27

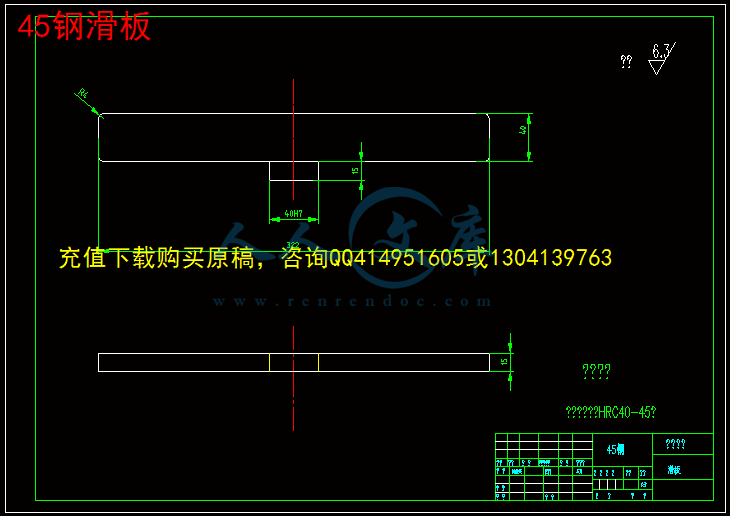

4.7夹具体设计29

4.7.1 对夹具体的要求29

4.7.2 夹具体的结构设计29

4.7.3 加工方案31

4.8夹具与机床的链接31

4.8.1 对刀元件31

4.8.2 夹具与机床的链接31

5 液压系统的设计33

5.1 对液压系统的要求33

5.2工件进给系统的计算33

5.2.1 工况分析33

5.2.2 液压缸的载荷组成与计算33

5.2.3 液压缸的主要尺寸的确定34

5.3控制元件设计及液压系统图36

5.3.1 流量控制设计36

5.3.2 压力控制设计37

5.3.3 能耗控制设计37

5.3.4 拟定液压系统图37

5.4 元、辅件规格的选择38

5.4.1 泵及驱动电机规格选择38

5.4.2 元辅件的选定39

5.4.3 结构配置设计39

5.4.4 性能验算39

5.5 工进进给系统分析40

5.6 液压系统的调试与维修41

5.6.1 液压系统的调试41

5.6.2 液压系统的维修42

6 结论与展望43

6.1结论43

6.2不足之处及未来展望43

致 谢44

参考文献45

1 绪论

1.1 力源压缩机有限公司简介

力源压缩机有限公司是在历史名城无锡,原第二压缩机厂改组建的有限责任公司,专业制造空气压缩机和空气净化设备的专业公司。从20世纪60年代末开始生产微型、小型压缩机。20世纪80年代末开始批量出口微型压缩机主机,目前已成为中国微、小型压缩机主要出口企业之一。

川公网安备: 51019002004831号

川公网安备: 51019002004831号