摘 要

在组合机床的设计中,主轴箱加工工艺是关键。“三图一卡”包括加工零件工序图,加工示意图, 机床总图,生产效率计算卡。其中加工零件工序图是表示一台组合机床对被加工零件应完成的工艺内容的示意图。它包括加工部位尺寸精度,表面粗糙度及技术要求等内容。加工示意图表明被加工零件在机床的加工过程,刀具,辅具的位置状况,工件与夹具,刀具等机床各零部件间的位置关系,以及机床的工作行程和工作循环等。机床总图表示机床各组成部件相互配合关系及各零件、部件、标准件、通用件等名称、代号、数量及运动关系。以及检验各部件的相对位置及尺寸之间联系是否满足加工要求,通用部件是否合适等内容。

关键词:组合机床 主轴箱 “三图一卡”

Abstract

In transfer and unit machine design, the headstockprocessing craft is a key. "A three charts card" including processingcomponents working procedure chart, processing schematic drawing,engine bed assembly drawing, production efficiency computation card. Processing components working procedure chart is expressed a aggregatemachine-tool to is processed the craft content schematic drawing whichthe components should complete. It including processing spot sizeprecision, content and so on surface roughness and specification. The processing schematic drawing indicated is processed the componentsin the engine bed processing process, the cutting tool, auxiliaryposition condition, work piece and jig, position relations engine bedvarious spare parts and so on between cutting tool, as well as enginebed power stroke and operating cycle and so on. The engine bed assembly drawing expressed the engine bed eachcomposition part mutually coordinates the relations and variouscomponents, the part, the standard letter, General Work piece and so on thename, the code number, the quantity and the movement relations.Examines various parts between the relative position and the sizerelates whether satisfies the processing request, the general part is whether appropriate and so on the content.

Key words: transfer and unit machine Headstock "a three charts card"

目录

一、设计任务书…………………………………………..6

二、概述…………………………………………………..7

(一) 组合机床的设计内容…………………………7

(二)组合机床的功用及未来的发展…………………8

三、组合钻床的总体设计………………………………..10

(一)工艺过程分析………………………………….10

(二)“三图一卡”设计…………………………….12

1.被加工零件工序图…………………………12

2.加工示意图………………………………….13

3.机床总图…………………………………….17

4.生产效率计算卡…………………………….20

四、组合机床的专题设计…………………………………23

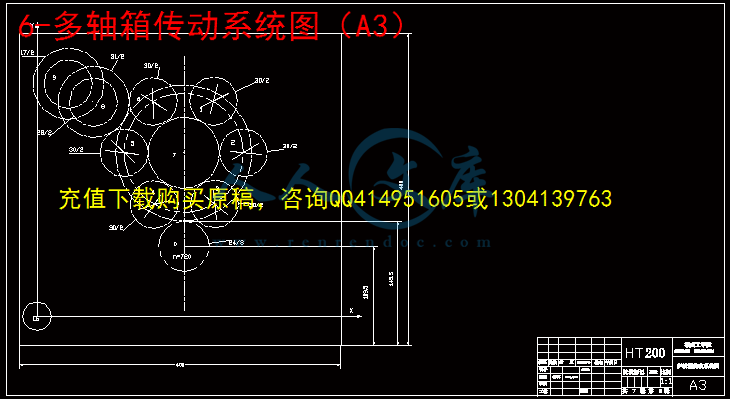

(一)组合机床的主轴箱传动系统设计……………..23

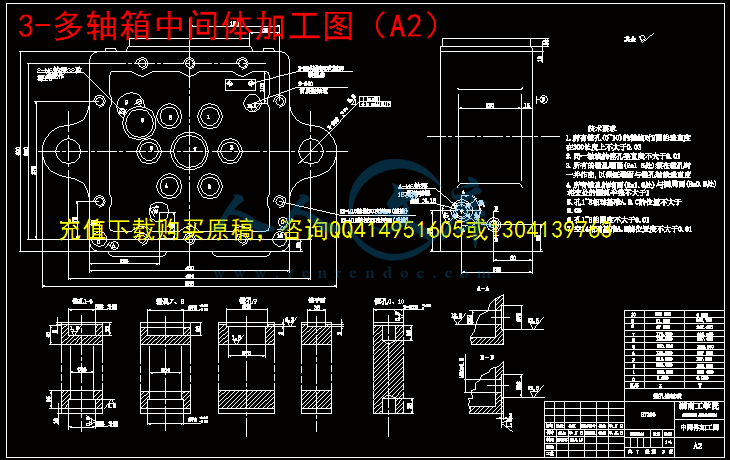

(二)组合机床多轴箱的设计………………………..27

五、多轴箱补充加工图……………………………………31

六、多轴箱CAD系统………………………………………32

七、设计总结………………………………………………33

八、参考文献……………………………………………….34

二、概述

(一) 组合机床(transfer and unit machine)的设计内容

组合机床是按系列化,标准化通用件及按工件的形状和加工工艺要求设计的专用件所组成的高效机床,组合机床90%为通用件,10%为专用件,故来加工产品有很大的优点.

组合机床的特点:

1.主要用于棱体其零件和杂件的孔面加工.

2.生产高,因工序集中,可多共面、多轴、多刀同时加工.

3.加工精度稳定.

4.研制周期短、便于设计、制造和使用维护,成本低.

5.自动化程度高,劳动强度低.

6.配置灵活,因结构是横块化,组合化,可按工件或工序,因大量通用部件和少量部件灵活组成或各种类型的组合机床及自动化.

川公网安备: 51019002004831号

川公网安备: 51019002004831号