两侧面组合铣床及主轴箱设计

摘要: 本课题设计一台粗铣柴油机气缸体两侧面的组合铣床,主要完成组合铣床的总体设计及其主轴箱的设计。

根据零件的结构特点、加工部位、尺寸精度、表面粗糙度及生产率等要求,确定该机床为单工位卧式组合机床;考虑工件尺寸精度,表面粗糙度,切屑的排除及生产率等因素,选用硬质合金不重磨式面铣刀;根据工件的尺寸、特点及其材料选择切削用量;然后,再经过切削用量来确定组合机床的通用部件;最后进行组合机床的总体设计。

在设计之中,尽量选用通用件,减少了制造成本,增加了经济效益。通过本次设计可以达到效果是:所设计的组合铣床和夹具能满足其工作状态的质量要求,使用时安全可靠,易于维修。

关键词:组合铣床;万向节滑动叉;铣刀;夹具

Two sides modular milling machine and jig design

Abstract: This topic designs a thick mill diesel engine to be mad the cylinder body two sides the combination milling machines, Mainly completes the design work of machine tool overall and the jig design.

According to the request of construction features, processing spot, size precision, surface roughness and productivity that diesel engine air cylinder, sets the machine tool for single location horizontal type modular machine tool. Considered to the factor of the size precision, surface roughness, scrap removes and productivity and so on of the work piece, selects the Hard alloy not grind type surface milling cutter. According to work piece size, characteristic and its material choice cutting specifications; Because of the thick mill diesel engine cylinder body two sides, then the jig design use "two sells the localization at the same time", Manual clamps, an attire clamps processes the diesel engine to be mad the cylinder body two sides; according to will work receives the cutting force to calculate clamps the strength; again according to clamps the strength , choose the determination clamp the special-purpose part.

During the design, the standard parts are selected as far as possible, to reduced the production cost, increased the economic efficiency. This design may achieve the effects as fowllows: the modular milling machine and the jig can satisfy its the quality requirement at working status,it’s safe, and easy to service.

Key word: the modular milling machine; air cylinder; milling cutter; jig

目 录

1 前言………………………………………………………………………………1

2 总体方案论证……………………………………………………………………3

2.1工艺方案设计……………………………………………………………………3

2.2加工设备方案选择………………………………………………………………3

2.3确定机床的总体布局……………………………………………………………4

3 切削用量的选择和计算…………………………………………………………5

3.1切削刀具选择……………………………………………………………………5

3.2切削用量的选择…………………………………………………………………5

3.3确定切削力,切削转矩,切削功率……………………………………………6

4 组合机床通用设备的选择………………………………………………………7

4.1进给动力部件选择………………………………………………………………7

4.2主运动动力部件选择……………………………………………………………8

4.3通用主轴部件选择…………………………………………………………… 8

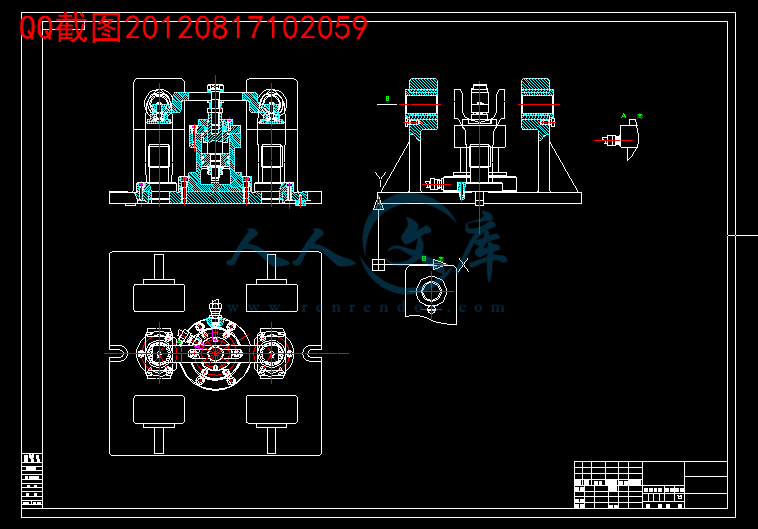

5 组合机床总体………………………………………………………………… 10

5.1被加工零件工序图…………………………………………………………… 10

5.2加工示意图…………………………………………………………………… 11

5.3机床总联系尺寸图…………………………………………………………… 12

5.4机床生产率计算卡…………………………………………………………… 13

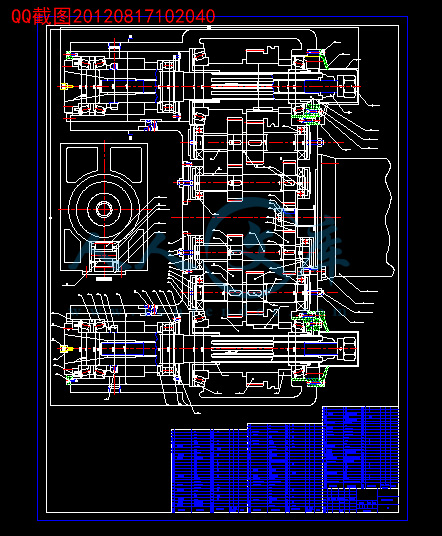

6 主轴箱设计……………………………………………………………………… 15

6.1主轴箱设计的原始依据………………………………………………………15

6.2 运动参数和动力参数的确定…………………………………………………16

6.2.1 传动系统传动比分配………………………………………………………18

6.2.2 计算传动装置的运动和设计参数…………………………………………19

6.2.3齿轮模数的估算及其叫校核………………………………………………22

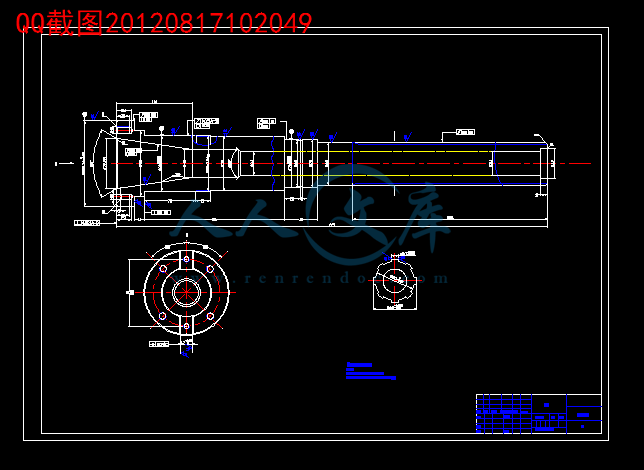

6.2.4 轴各参数估算及强度校核……………………………………………… 23

6.3主轴箱的坐标计算……………………………………………………………25

7 结论…………………………………………………………………………… 27

参考文献…………………………………………………………………………… 29

致谢…………………………………………………………………………………30

附录………………………………………………………………………………… 33

1 前言

组合机床是根据工件加工要求,以大量通用部件为基础,配以少量专用部件组成的一种高效专用机床。组合机床的设计,有以下两种情况:其一,是根据具体加工对象的具体情况进行专门设计。其二,随着组合机床在我国机械行业的广泛使用,广大工人总结自己生产和使用组合机床的经验,发现组合机床不仅在其组成部件方面有共性,可设计成通用部件,而且一些行业的在完成一定工艺范围的组合机床是极其相似的,有可能设计为通用机床,这种机床称为“专能组合机床”。这种组合机床就不需要每次按具体加工对象进行专门设计和生产,而是可以设计成通用品种,组织成批生产,然后按被加工的零件的具体需要,配以简单的夹具及刀具,即可组成加工一定对象的高效率设备。

川公网安备: 51019002004831号

川公网安备: 51019002004831号