摘要

组合机床是根据工件加工需要,以大量通用部件为基础,配以少量专用部件组成的工序集中的一种高效专用机床。而且其生产效率高,加工精度稳定,自动化程度高,使工人劳动强度降低。

本次设计的是一台加工“汽车制动室支架”的组合钻床,主要用来一次性加工完成汽车制动室支架的二个零件,共计10个孔,一次安装两个工件,左主轴箱钻4孔,右主轴箱钻6孔,我负责设计的是右主轴箱和中间底座的设计。

根据所加工孔的位置及速度要求,算出切削速度和主轴转速,确定右主轴箱轮廓尺寸、主轴的型式和直径。再根据驱动轴位置和转速、各主轴位置及其转速要求,合理布置传动轴的位置,把驱动轴和各主轴连接起来,使各主轴获得所需转速和转向,完成钻孔。

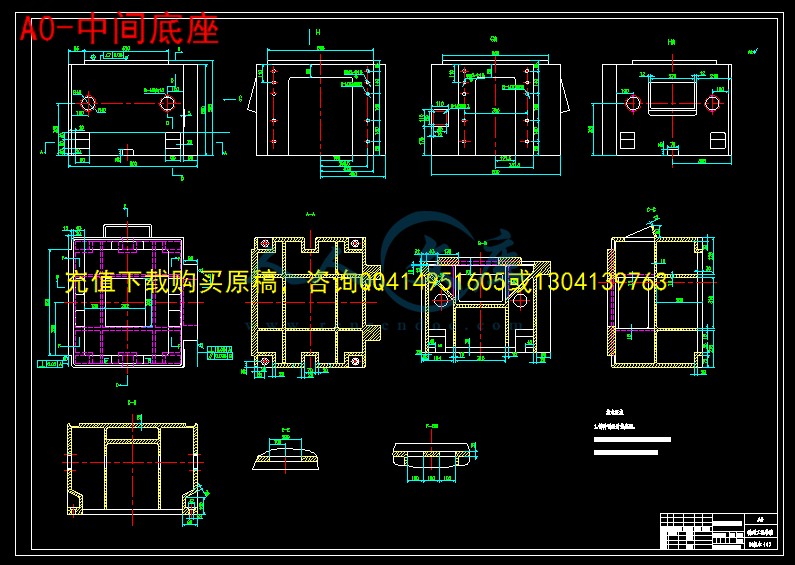

中间底座的结构、尺寸则需要根据工件的大小、形状以及组合钻床的配置形式等来确定。

由于组合钻床能够进行多工位加工,提高自动化程度,缩短加工时间和辅助时间。而且组合钻床大部分都是由通用部件组成,研制周期较短,便于设计、制造和使用维护,成本低。而且机床易于改造,产品和工艺变化时,通用部件还能重复利用,经济性较好。所以组合机床在大批量生产中的应用十分广泛。

关键词:组合钻床;主轴箱;中间底座

Abstract

Combination machine is based on the workpiece processing needs,take a large number of general part as the foundation, with a few of dedicated part which composes the focus on process of a efficient special machine.Moreover its production efficiency is high,machining accuracy is stable, degree of automation is high,cause the workers labor intensity to reduce.

This design is a combination drilling machine of processing "automobile brake room stent" , mainly uses for complete two parts of automobile brake room stent which processing a one-time, the total 10 holes, one-time installs two workpieces, the left spindle box drills 4 , the right spindle box drills 6 , what I am responsible to the design of the right spindle box and the middle base .

According to processes the hole the position and the speed request, calculated to cutting speed and the spindle speed ,determines the right spindle box outline of size, the spindle type and the diameter.Then according to drive shaft position and speed, various spindle position and rotational speed request, reasonable arrangement transmission shaft location, connects the drive shaft and various spindle ,causes various spindle to obtains needs the rotational speed and change direction , completes the drill hole.

The middle base’s structure , size has to be based on the workpiece size, the shape as well as the combination drilling machine configuration form and so on to determined.

Due to the combination drilling machine carries on the multi-location processing, improves the degree of automation, reduces processing time and auxiliary time. Moreover the combination drilling machine majority is composed of general part, the development cycle is short,and is advantageous for the design, the manufacture and use maintenance, the cost is low. Moreover the machine easy to transform, when product and process changes, the general part can also the reuse,the efficiency be good.So combination of machine tools is very widespread in production in enormous quantities application.

Keywords: combination drilling machine spindle box middle base

目 录

1 组合机床概述1

1.1 引言1

1.2 组合机床组成及特点1

1.3 组合机床的工艺范围及配置形式2

1.3.1 组合机床的工艺范围2

1.3.2 组合机床的配置形式3

1.4 组合机床的设计步骤5

1.4.1 调查研究5

1.4.2 总体方案设计5

1.4.3 技术设计6

1.4.4 工作设计6

2 组合钻床设计7

2.1 零件分析7

2.2 组合钻床设计的组成及设计任务7

2.2.1 组合钻床设计的组成7

2.2.2 本课题主要任务7

2.3 工艺方案及基准的选择8

2.3.1 确定组合钻床工艺方案的机本原则8

2.3.2 组合钻床工艺方案的一般步骤9

2.3.3确定切削力、切削转矩、切削功率及刀具耐用度10

2.4 组合钻床主轴箱概况10

2.4.1 组成10

2.4.2主轴箱的通用零件10

2.5 工序与计算11

2.5.1 加工条件11

2.5.2计算切削速度、主轴转速11

3多轴箱的设计13

3.1 多轴箱的基本结构和表达方法13

3.1.1 多轴箱的简介13

3.1.2多轴箱的组成13

3.1.3多轴箱总图绘制方法13

3.2 多轴箱通用零件13

3.2.1 通用箱体类零件14

3.2.2 通用主轴14

3.2.3 通用传动轴14

3.2.4 通用齿轮和套14

3.3通用多轴箱的设计分析15

3.3.1 绘制多轴箱设计原始依据图15

3.3.2 确定多轴箱轮廓尺寸16

3.3.3 主轴型式和直径的确定16

3.3.4主轴箱所需进给力计算18

3.3.5 主轴箱所需功率计算18

3.3.6 动力部件19

3.3.7多轴箱传动设计19

3.3.8 计算传动轴的坐标23

3.3.9 润滑油泵和手柄轴的安置24

4 中间底座的设计26

4.1 引言26

4.2 中间底座的作用及基本要求26

4.2.1 中间底座的作用26

4.2.2 对于中间底座的基本要求26

4.3 中间底座的设计原则27

4.3.1 合理选择截面形状和尺寸27

4.3.2 合理布置加强筋27

4.4 中间底座壁厚、加强筋厚度的选择27

4.5 如何提高连接处的局部刚度和接触刚度28

4.6 中间底座结构工艺性28

结论29

参考文献30

致谢31

附录32

1 组合机床概述

1.1 引言

随着生产部门生产批量的增加,如何提高生产效率和加工精度,便成了工厂急待解决的问题。于是,组合机床便应运而生。组合机床是由大量通用部件和少量专用部件组成的工序集中的高效率专用机床,它能对一种(或几种)零件进行多刀、多轴、多面、多工位加工。不仅生产效率高,而且加工精度稳定.现在大批量生产企业,组合机床已被广泛应用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号