钻铣组合机床设计【5张CAD图纸+毕业答辩论文】

收藏

资源目录

压缩包内文档预览:

编号:451623

类型:共享资源

大小:809.12KB

格式:RAR

上传时间:2015-07-07

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

45

积分

- 关 键 词:

-

组合

机床

设计

全套

cad

图纸

毕业

答辩

论文

- 资源描述:

-

摘要

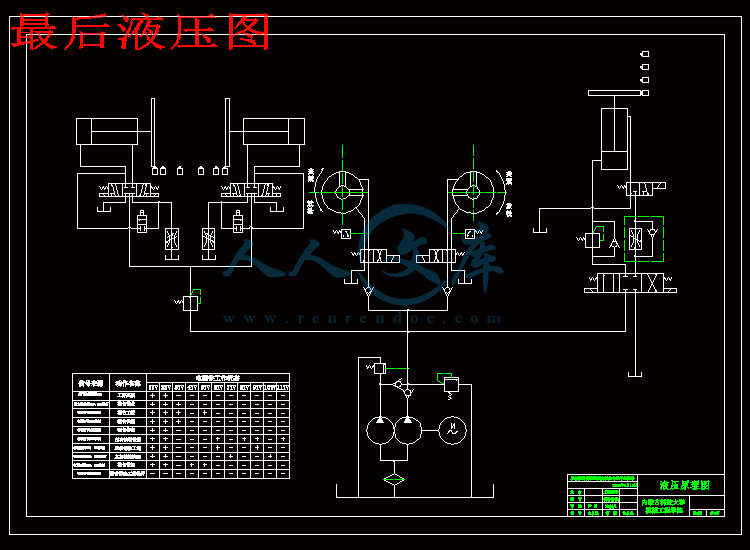

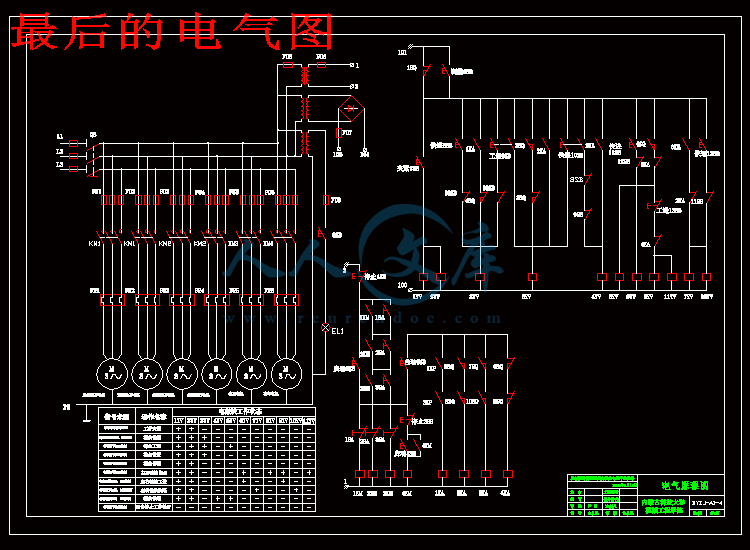

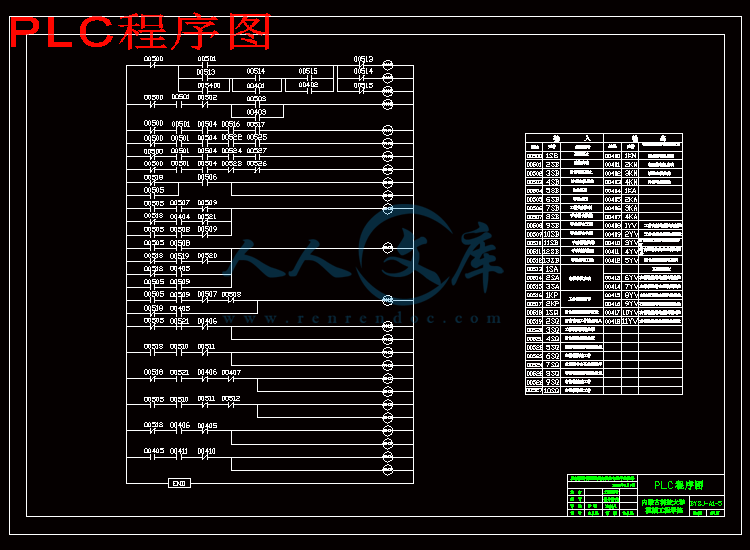

本次毕业设计的题目是“液压半自动钻铣组合机床”。本组合机床要求能实现钻中心孔和铣两端面,能进行手动和自动控制,铣削头能作10mm的微调。本人的设计的主要内容是:进行了机床总体布局设计;对机床的进给和传动部分进行了设计;机床料架的夹紧方案的选取和设计;对机床液压系统进行了设计,绘制了液压原理图;最后根据液压图和系统的工作循环,设计了电气控制系统,并编制了PLC 程序图。

通过此设计,本机床完全能满足设计要求,与传统的机床相比,本机床具有自动化程度高,生产率高,精度高等优点。

关键词:组合机床;铣削头;工作循环;自动

Abstract

The topic of this graduation design is"The Hydraulic Pressure Module Machine Tool of Drilling & Milling".This module machine tool needs to be realized to drill the center bore and mill the ends of the axle.Also it can do with automatic control and by hand. The cutter head can move 10 mm forward or backward.The main contents of my design is: To proceed the total distribution in machine tool in machine design;To design the entering and moving parts of the module machine tool;To design the hydraulic of the machine tool and draw the hydraulic system principle diagram;finally according to the hydraulic diagram and the circulation of the work of the system system, design the electricity control system, and draw up PLC procedure diagram.

Passing this designs, this machine tool can satisfy completely the design requests. compared with traditional machine tool, this machine has the high degree automation and high precision, also the rate of production is high.

……………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………………….

Key words: module machine tool; the cutter head ; work circulation ; automation

目 录

摘 要

Abstract

第一章 引 言

第二章 设计题目简介及总体方案确定6

2.1 题目简介6

2.1.1 设计题目6

2.1.2 题目简介6

2.1.3设计参数及性能要求6

2.1.4现场加工设备简介6

2.2机床设计方案确定7

2.3液压系统的设计原则和设计依据8

2.4组合机床及其自动线电气控制系统设计9

第三章 铣削用量的选择和铣削力的计算10

3.1加工工件简介10

3.2铣削用量选择及铣削力的计算10

3.3钻削用量选择及钻削力的计算12

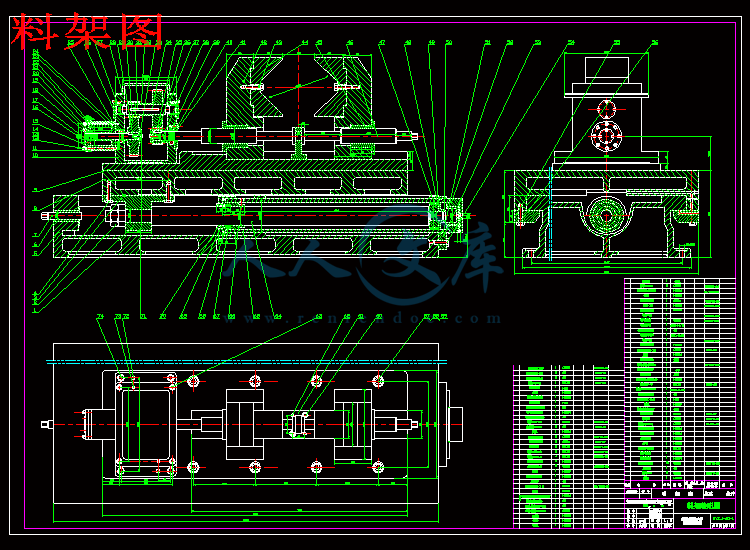

第四章 料架的设计13

4.1料架的组成及其工作原理14

4.1.1 料架的组成14

4.1.2 料架的工作原理14

4.2 V型块的设计14

4.2.1 V型块外形尺寸确定14

4.2.2 V型块的夹紧力计算15

4.3左右螺旋丝杠的设计16

4.4变速器的设计20

4.4.1变速器传动比分配20

4.4.2变速器齿轮设计20

4.5轴的设计21

4.5.1丝杠螺杆轴的设计21

4.5.2单叶片摆动液压马达输出轴的设计22

第五章 液压系统的设计计算22

5.1动力滑台部分

5.1.1 动力和运动参数分析

5.1.2 工作负载分析

5.1.3 负载图和速度图的绘制24

5.1.4 液压缸主要参数确定25

5.2动力钻头部分29

5.2.1 动力和运动参数分析29

5.2.2 工作负载分析30

5.2.3 负载图和速度图的绘制31

5.2.4钻轴伸缩油缸的设计计算32

5.2.5钻轴伸缩油缸缸筒的设计计算32

5.3旋转油缸的设计计算33

第六章 传动部分的设计计算34

6.1电机的选择35

6.2主轴直径的选择35

6.3主轴箱传动齿轮的设计36

6.3.1动力运动参数分配36

6.3.2传动齿轮设计37

第七章 组合机床电气控制系统的设计44

7.1概述45

7.2组合机床液压电气回路及其控制系统的设计45

7.3机床加工总时间的确定46

参考文献48

致谢49

第一章 引言

对于培养工程技术人才的工科性大学来说,学生们的实践活动就显得非常重要。然而,四年的大学生活,我们基本是以书本上的理论学习为主,实习大都以参观为主,基本上没有什么自己动手操作的机会,所以,提高学生的实践动手能力和熟悉工程现场的能力是很必要的。而最后的毕业设计,是真正的理论与实践相结合,综合运用大学四年所学知识解决工程实际问题的过程。所以,我们要充分珍惜这难得的机会,努力提高自己,为以后的工作打下良好的基础。

- 内容简介:

-

内蒙古科技大学毕业设计 外文翻译 1 Dimensional Tolerance Allocation for New Type of Parallel Machine Tools 1 INTRODUCTIONS The prototype of a new type of parallel machine tools is a 6-6 Stewart platform mechanism. Compared to the traditional machine tool, a parallel machine tool possesses many advantages, such as high precision, high structural rigidity and high machining force/torque capacity, etc. Currently, many universities have research on this kind of machine tools. As shown in Fig.1, the parallel machine tool comprises the following four parts: a fixed platform, six in-parallel actuators, the length variation of each actuator is implemented by ball-screws and the ball-screws are driven by servo motors. The ball joints connect the fixed and moving platforms with ball-screws; a spindle is installed on moving platform bottom. When machining work is being carried out the variation of the moving platform allows a parallel machine tool to machine complicated curved work piece such as die, impeller etc. The developing tendency of modern NC machine tools is high speed and high precision, and the machine tool errors have direct effect on machine tool precision. In order to meet the precision specified, a scientific dimensional tolerance allocation is urgently required in the design of this kind of machine tool. The errors of the machine tool include the following parts: 1)transmission error in transmission chains, i.e. ,pitch cumulative error of the ball-screw in each actuator and dead domain error during starting or reversing operation;2)length transform error of the ball-screw due to the influence of ambient temperature;3)pares clearance error that connect fixed and moving platform;4)other errors, i.e. , positioning error caused by transmission rigidity, dynamic error caused by moving parts mass and velocity damping. The above errors will finally lead to error at the cutter head of the machine tool. This paper will carry out research on dimensional tolerance allocation based on a kind of statistical experiment method, Monte-Carlo method. nts内蒙古科技大学毕业设计 外文翻译 2 2 SOLUTION OF INVERSE KINEMATICS FOR MACHINE TOOL The kinematics solution for this parallel machine tool can be classified into two types. When the known quantity is the lengths of the six actuators and the orientation of the cutter head, this is called direct kinematics; On the contrary, when the known quantity is the position and the orientation of the cutter head and the unknown quantity is the lengths of the six actuators, this is called inverse kinematics. The solution of the direct kinematics of the machine tool is used to monitor while the solution of the inverse kinematics of the machine tool is used to control. As shown in Fig.2, a fixed coordinate frame O-XYZ is attached to the fixed platform and a moving coordinate frame O-XYZ is attached to the moving platform. The center of the joint connecting the itch actuator to the fixed platform will be denoted as )6,2,1( iai whereas the center of the joint connecting the same leg to the moving platform will be denoted as )6,2,1( ibi , the Y-axis of the fixed coordinate frame is selected along the line which bisects the angle 61Oaaand the Y-axis of the nts内蒙古科技大学毕业设计 外文翻译 3 moving coordinate frame is selected along the line which bisects the angle 61Obb. Let the position of point O with respect to the origin of the fixed coordinate frame be denoted by vector TzyxR0000 , vectors )6,2,1(, izyxR Tbibibibi will be defined as the position vectors of the moving coordinate frame, thus we can write the position vectors of the moving platform joints in fixed coordinate frame as : )6,.2,1(, 000 izyxzyxQzyxR TTibbibiTbibibibi Where matrix Q is the rotation matrix describing the orientation of the moving platform with respect to the fixed platform, the elements of matrix Q are shown by RPY expression. Let , be angles that the moving platform rotates about X-axis, Y-axis, Z-axis of the fixed coordinate frame, and then we can obtain: ccsscsscscscssccasascasasacacsasacacdddddddddQ333231232221131211 nts内蒙古科技大学毕业设计 外文翻译 4 Let vectors Taiaiaiai zyxR be the position vectors of the platform joints with respect to the fixed coordinate frame, then the length of each actuator can be written as: 6,2,1, iRRLi aibi 3 DIMENSIONAL TOLERANCE ALLOCATIONS WITH MONTE-CARLO METHOD 2.1 Determination of Total Dimensional Chain Error of the Machine Tool Links In order to carry out dimension tolerance allocation, the variation feature between the errors of the in-parallel links and orientation error of the cutter head (or the center point of the moving platform) need to know. The direct kinematics is used to derive the cutter head error from the link errors of the machine tool. It is difficult to obtain analytical solution by direct kinematics. So an inverse error estimation method by which the link errors can be derived from the position and orientation errors of the cutter head is adopted. The key to the dimensional tolerance allocation is to determine the total dimensional chain error of the machine tool links. Monte-Carlo method is a numeral method to solve mathematics based on random sampling. In this parallel an evenly-distributed Monte-Carlo random simulation method on a certain position and orientation precision of the cutter head is used. By Esq. (1) the lengths of the machine tool links under the sample volume can be obtained. The maximum length error of each link can be obtained in different positions in the machine tool workspace. Take the minimum length errors as the total error for dimensional tolerance allocation of each link. Before random simulation by Monte-Carlo method, the machine tool precision should be estimated and the variation of the moving platforms position and orientation should be determined. Let the position and orientation of the center point of the moving platform be three transforming quantities and three rotating quantities Tzyx . A simplified model of spindle system for parallel machine too is shown in Fig.3. From the figure we can see that point a and b represent nts内蒙古科技大学毕业设计 外文翻译 5 cone bearings, segment bc represents cutter holder and segment cd represents the cutter, the cutter head point d bears machining force P. 4 CONCLUSIONS The presented dimensional tolerance allocation method is the combination between machine tool precision and the actual dimension tolerances. The factors that influence on the cutter head errors of the parallel machine tool are analyzed first. Due to the multi-solution and the difficulty in obtainment of the analytical solution of the direct kinematics, the derivation of the cutter head error from the error of machine tool links is difficult. So a inverse error estimation method to derive errors of links from cutter head error is presented in this paper. To a certain spindle dimension of the parallel machine tool, the total dimensional tolerance of the machine tool link can be determined by Monte-Carlo random simulation method. The dimensional tolerance allocation for adjustable loop of the link is developed. If the allocated dimension tolerance can not meet the design or manufacturing requirement, the adjustments towards precision grade of the ball screw or the spindle dimension are desired for tolerance re-allocation. Example shows the presented tolerance allocation method is reasonable. This work provides a basis in the design stage of the parallel machine tool. nts内蒙古科技大学毕业设计 外文翻译 6 一种新型并联机床的尺寸公差分配 1介绍 新类型的并联机床的原型是一个 6-6 斯图尔特平台 机构 。与 普通机床 相比,并联机床有许多优点,比如高的精度,高的结构刚度和高机制力量 /转力矩能力等。现在,许多大学都对这种并联机床都加以研究。如 图 1所示。并联机床包括四个部分:一个固定的平台,六个平行的主动件,每个主动件的长度变化由球铰链 来控制,而球 铰链 由伺服马达驱使。球关节用 铰链 连接固定部分和可动部分,转轴安装在移动平台底部。当机加工进行时,移动平台使并联机床能加工复杂的工件,如钢模的复杂弯工作块及其他的东西。 现代的 控制母机的发展趋向是高速度和高精度,并且机床的误差应能直接影响机床的精度。为了解决这种精密的需要,一种尺寸公差分配方法需要应用于 机床的设计中。 机床 的误差包括下列各项部分:( 1)传输链的传输误差,也就是,在开始或颠倒操作的时候在每个主动件 和死区中球 铰链 的累积误差( 2)周围温度变化导致的球 铰链 长度变化误差( 3)剥连固定和可动工作台的清除误差( 4)其它的误差,也就是,由移动部分块和速度降低引起的动态误差。上述的误差最终会导致在工作母机的切削头上产生的误差。这篇论文将对一种基于统计的尺寸公差分配的实验方法 蒙地卡 罗方法加以研究。 nts内蒙古科技大学毕业设计 外文翻译 7 2 机床 的 逆向 运动学的解决 运动学解决这种并联机床的运动学解决方法可以分为两类。当已知量是六个主动件 的长度和切削头的方向的时候,这叫做 正向 的运 动学。另一方面,当已知量是位置和切削头的方向而未知量是六个主动件 的长度的时候,这叫做 逆向 的运动学。并联机床的 正向 运动学用于解决检测问题,而 逆向 运动学用于解决控制问题。如图 2 所示,固定的坐标 系 XYZO 附在固定的平台上,而移动的坐标 系 ZYXO 附在移动的平台上。连接主动 件 到固定 的平台关节的中心被表示为)6,2,1( ia i ,同样,连接相同的腿到那个移动平台的关节中心被表示为)6,2,1( ibi 。固定坐标 系 的 Y 轴是按沿着角 61Oaa 挑选的,而移动坐标 系 的Y轴是沿着角61Obb。让有关固定的坐标 系 的起源用矢量 TzyxR0000 表示,而移动坐标 系 的起源用矢量 )6,2,1(, izyxR Tbibibibi 表示。如此,我们把移动平台的位置在固定平台中用位置矢量表示为: nts内蒙古科技大学毕业设计 外文翻译 8 )6,.2,1(, 000 izyxzyxQzyxR TTibbibiTbibibibi 点阵式 Q 是描述移动平台相对于固定平台的旋转点阵式,点阵式 Q 元素用 RPY表示。让 , 为移动平台与 X轴,

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号