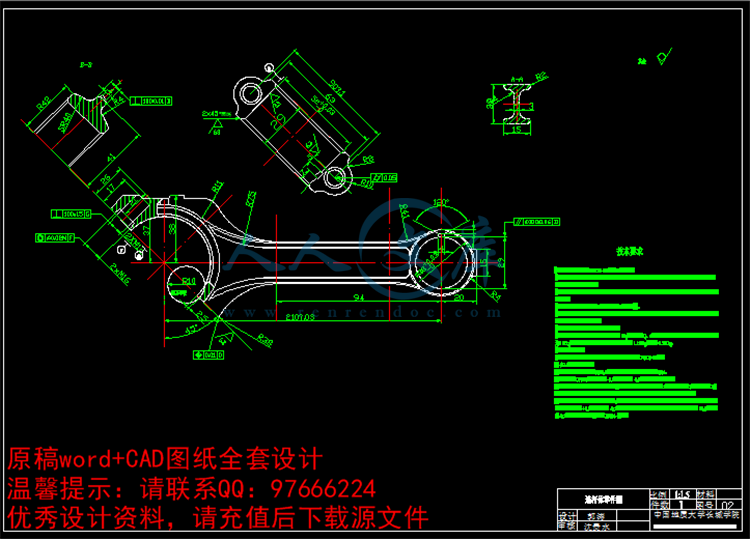

连杆生产线连杆体钻两孔夹具设计【4张图纸】【夹具毕业设计优秀】

收藏

资源目录

压缩包内文档预览:

编号:453888

类型:共享资源

大小:1.25MB

格式:ZIP

上传时间:2015-07-08

上传人:小***

认证信息

个人认证

林**(实名认证)

福建

IP属地:福建

46

积分

- 关 键 词:

-

连杆

生产线

体钻两孔

夹具

设计

图纸

毕业设计

优秀

优良

- 资源描述:

-

目 录

1.前言1

2.零件的分析2

2.1计算生产纲领,确定生产类型2

2.2 连杆体的加工工艺分析3

2.2.1连杆机械加工工序安排3

2.2.2连杆体加工的主要技术要求 3

2.2.3连杆的材料和毛坯3

2.2.4连杆机械加工的定位基准3

3.工艺规程设计4

3.1零件表面加工方法的确定4

3.2工序设计5

3.2.1选择加工设备与工艺设备5

4.钻床的设计6

4.1连杆加工工序6

4.2初算加工时间6

4.2.1时间定额的确定6

4.3工件的夹紧6

4.3.1夹紧力方向及切削力的确定6

4.4夹紧机构的选择7

4.5气缸的确定8

4.6底座的确定8

4.6.1底座材料的确定8

4.6.2底座设计方案选择8

4.7定位销的选择9

4.8钻模板的选择10

4.8.1钻模的选择10

4.8.2钻套的选择10

4.8.3尺寸的确定10

4.9定位块的选择11

5.夹具设计基本要求及简要说明11

5.1 夹具设计的基本要求11

5.2夹具操作简要说明12

6.总结12

参考文献13

致 谢14

- 内容简介:

-

连杆生产线连杆体钻两孔夹具设计 摘 要 连杆是发动机的主要零件之一,它连接活塞和曲轴,把作用于活塞顶面的膨胀气体的压力传递给曲轴;将活塞的往复运动变为曲柄的旋转运动,又受到曲轴的驱动而带动活塞压缩汽缸中的气体。 本文在参阅了国内外大量文献资料的基础之上,分析了连杆零件的加工工艺规程,其中重点介绍了螺孔、螺栓孔的加工方法,并设计了一种用于连杆螺栓孔加工的专用夹具,以介绍设计方法为宗旨,着重实力,力图做到内容完整、详实。 本文共分为两部分,第一部分为机械制造工艺规程设计的基本要求、内容、方法和步骤;第二部分详 细的论述了对专用机床夹具的基本要求和设计步骤以及简要的说明夹具体的设计要求和步骤。 关键词 : 专用钻床夹具 ; 工艺规程 ; 切削用量 ; 加工余量 nts Abstract The design of the components on the link order processing and special fixture design in order to design methods introduced for the purpose. focus on strength, in a bid to ensure the content is complete, informative. The book has two chapters, the first of the machinery manufacturing process planning the basic requirements, contents, methods and steps; 2nd detail in the chapter sequence of the special fixture and the basic requirements for the design steps and brief description of the specific folder design Summation steps. Key words : exclusive drilling fixture ; Technology of cutting; consumptional ; lowance nts中国地质大学长城学院毕业设计 外文资料翻译译文 从生态加工技术对攻丝的研究 摘 要 这项研究是关于攻螺纹(扭矩,攻丝,磨损,工作硬度等)的加工特性。在生态加工技术操作下,涂有 TiN 的 MMC(铝合金金属复合材料)攻螺丝形成的攻丝得到了调查,并与没有涂层的特性进行了比较。下面的结果就是从这份研究中得到的: 1.TiN 涂层攻丝的刀具寿命是没有攻丝的四倍 ; 2.有 TiN涂层的攻丝形成的螺纹比没有的加工硬化要低。 关键词: 攻丝 ; 攻螺丝 ; 螺纹 ; 生态加工 ; 钻孔 1 引言 螺栓、螺钉机械连接中的螺纹是机械部件的最重要紧固系统之一。螺 纹制造有很多种方法,特别攻螺丝是用来生产内螺纹的有效的技术。 最近,每年都强调增加生产力。据说现在的车间里,最重要和最严重的问题是提高生产力。怎样改善孔加工(钻 /铰孔和攻丝)已成为一个严重的问题。传统的刀具材料限制了生产力的提高,如高速钢刀具加工铝合金金属复合材料( MMC)时刀具寿命很短由于碳化硅粒子的腐蚀天性。因此,刀具的磨损和破坏阻碍了生产力的提高。为了实现理想的生产力,攻丝已经吸引了车间工程师的注意。 在这项研究中,用攻丝加工 MMC,利用攻丝(扭矩,攻丝磨损,工作硬度等)的切割特点, 有 TiN涂层和没 有涂层的都进行了调查。 2. 实验方法 2.1 实验装置 攻丝试验在辛辛那提 5 NC-MC (5HP)进行。该(钻孔和攻丝) 仪器和数据采集系统如图 2.1。切削力(推力和扭矩)测定使用三个类型 9273 压电电力测功器和相应的场所用 5007 电荷放大器放大。得到的信号,然后传递到 A / D 转换器 AZI-16-12 ,连接到个人电脑。切削力测量安装如图 2.2。 2.2 工件,钻及塔 在本实验中使用的工件是铝合金( 2618 MMC)的增强, 15碳化硅颗粒。形成无槽丝nts中国地质大学长城学院毕业设计 2 锥的螺纹是 M10如图 2.3 和两种类型的攻丝被用来在 调查过程中。 攻丝的形状类似于螺钉的形状( M10,孔距 1.5),无论有没有氮化钛涂层。 定位孔的直径 9.3mm,用于所有试验和聚晶金刚石攻丝钻孔(高速钢硬质合金碳化钨和聚晶金刚石钻孔)用在所有测试。本实验中用的钻头如图 2.4。 图 2.1 窃听器和数据采集仪器 图 2.2 Schmatic 图 的窃听系统 图 2.3 水龙头用于这项工作 2.3 仪表和检测方法的线程 线程的估计是用螺纹规来衡量。结果被分为 A等和 B等 1 。硬铝合金 2 螺纹深度是攻丝直径的 1.4倍。 甲等 -质量:直径通过整个螺纹测量 。 乙等 -质量:直径至少 15毫米。 图 2.5是显示的直径指标 (M10 1.5 ISO 6H)。 2.4 实验特性 攻丝试验时,切削速度(攻丝的转速)是 215 rpm和进给速度 0.1mm/rev ( 322.5mm/min)。冷却油(氯和硫免费热切割石油)手动供应。 3.实验结果与讨论 在 M10攻丝操作的推力和扭矩信号显示在图 3.1 。结果表明,随着螺纹扣数的形成,扭矩增大,离开孔时减小。然而,可以看到几乎没有推力的增加。 nts中国地质大学长城学院毕业设计 3 图 2.4 形状的聚晶金刚石钻头 图 2.5 螺纹规 3.1 转矩比较 图 3.2显示是先前所提到的有 TiN涂层和没有涂层的第 1孔和第 8孔攻丝的扭矩信号。 图 2.1 参数确定 图 3.1 图切削力信号根据窃听测试扭矩 图 3.2 比较扭矩信号(第 1 洞和第 8 洞)与扭矩 在攻丝操作的初始阶段显示推力和扭矩的增加。然而,当螺纹成形进入全速时,推力显示出下降的趋势伴随着扭矩的增加和攻丝缩回,在螺纹孔口也可以看到负扭矩的出现。 图 3.1 负推力值是攻丝偏离中心的结果是因为一方不正当的工件,刀具的安装或定位空的表面粗糙度。 上述不确定的因素是定位孔的表面 粗糙度。 当有 TiN 涂层第一孔的攻螺纹的攻丝扭矩值 8.7 Nm 而没有涂层的值是 11.2Nm,得到扭矩信号。因而,第一孔有涂层的相比没有涂层的扭矩减少了 28 。而对第 8 孔有 TiN涂层的扭矩相比没有涂层减少了 52 。 初始阶段和在攻丝突破点前扭矩信号的比较表明,没有涂层的攻丝扭矩减少要明显于有 TiN涂层的攻丝。可以说,就形成的攻丝而言,在车螺纹时工作是均匀分布在 刮削端 。扭矩的比较结果总结在图 3.3 。结果表明,有 TiN涂层的攻丝扭矩一般低于那些没有涂层的攻丝。 nts中国地质大学长城学院毕业设计 4 3.2 螺纹形式的比较 有 TiN 涂层和没有涂层的 攻丝的螺纹形式如图 3.4 。在螺纹孔, ,位置的横截面的放大图像以及 1, 4, 8号孔作了比较。 图 3.4是不同位置螺纹的照片模型,而图 3.5 是八号孔放大的图像。 可以从图 3.5 中看出,有 TiN 涂层攻丝形成的螺纹的侧面 没有异常。相反,没有涂层表明孔的进口和出口相应的号和号位置无规律。 图 3.3 比较扭矩信号同类型 图 3.4 阐明的轴向截面建制线程 为了验证上述的意见,对孔和进行详细的分析进行。结果总结在图 3.6 。图 3.6( a)和( b)给出了 1 号和 8 号螺纹孔各自的和位置的结果。可以观察图 3.6( a),有 TiN涂层的攻丝齿形远远优于没有涂层的。 3.3 比较加工硬化 当采用有 TiN涂层和没有涂层的攻丝车螺纹时,研究比较加工硬化的严重性。 本研究结果归纳于图 3.7 。选用了两种类型中 1号攻丝。 有 TiN 涂层和没有涂层的结果分别在图 3.7( a)和( b)。用能受 100 gw 的硬度测量硬度仪测量硬度。 结果表明,有 TiN 涂层的攻螺纹的硬度低于没有涂层的。上述结果表明,在以下几个方面,如螺纹形式和加工硬化等,有 TiN涂层的攻丝优于没有涂层的攻丝。 图 3.5 比较线程形式 图 3.6 比较扩大线程形式 3.4 刀具寿命的比较 nts中国地质大学长城学院毕业设计 5 有 TiN 涂层和没有涂层的攻丝被用来调查性能和攻丝的刀具寿命一样高。每种类型的攻丝反复进行 3次试验,。结果总结在图 3.8 。 螺纹规读数用 A,B 值评估。结果表明,在刀具寿命达到限制前,螺纹孔的平均数,是没有 TiN 涂层攻丝的 X = 13 和有涂层攻丝的 X = 49。有 TiN 涂层攻丝的刀具寿命是没有涂层的 3.8倍。 3.5 比较塔磨损 图 3.9 显示各种类型攻丝的刀具磨损,在实验中车螺纹后如图 3.8 所示。应当指出的是,所有用于比较的攻丝已充分达到刀具寿命。有 TiN涂层和没有涂层的攻丝分别如图 3.9( a)和( b),。可以看出,所有攻丝的刀具磨损点。此外,可以看到大量的磨损在分界线上。有 TiN涂层和没有涂层攻丝的比较,如放大点,结果表明,后者的磨损明显高于前者。就有 TiN涂层攻丝来说,在刀具磨损区可以看到覆盖的 TiN涂层。 图 3.7 比较硬度分布 图 3.8 用攻丝的刀具寿命的比较 图 3.9 用攻丝的刀具磨损比较 4.结论 nts中国地质大学长城学院毕业设计 6 4.1有 TiN涂层的刀具的寿命大约是没有涂层的刀具寿命的 4倍。 4.2和没有 TiN涂层的刀具相比,有涂层刀具的扭转力下降了 28 。 4.3和没有 TiN涂层的刀具相比,带有涂层的齿形螺纹刀具则显示出更少的不规则性。 4.4有 TiN涂层的刀具的硬度低于没有涂层的刀具。 4.5从以上结果显示, 有 TiN涂层的刀具在以下方面优于没有涂层的刀具:刀具寿命,螺纹样式和加工硬化等。 参考文献 1 WOLFGANGSTRACHE : Alternative Strategies for the Production of Threads in Aluminum-based SIC Reinforced Metal Matrix Composite (MMC) Alloy,1993. 2 Beitz.W : Dubbel-Taschhenbuch fuer den Maschinenbau. ISBN 3-540-52381-2, (1990), G15. 外文原文 A Study on Tapping Viewed from Eco-Machining Technology Abstract This study deals with machining characteristics of thread tapping (torque, tap, wear, workhardness etc.) The tapping of MMC (aluminum alloy metal matrix composite) with TiN coated forming taps under eco-machining technology operation, where chips are not produced and ejected from the tap flute, was investigated and compared with the characteristics during uncoated tapping. The following results are obtained from this study. 1.The tool life of TiN coated taps was 4 times longer than that of uncoated tap; 2.Threads formed with the TiN coated taps exhibit lower work hardening than those formed with uncoated taps. Keywords: Tap; Tapping; Thread; Eco-Machining; Drilling 1. Introduction Threads form the mechanical joint of a boltscrew connection, which is one of the most important fastening systems for mechanical components. There are many ways of thread making, nts中国地质大学长城学院毕业设计 7 especially that of tapping which has been employed as an efficient technique for the production of internal threads. Recently, the rise of productivity has been emphasized year by year. Also it is said that the improvement of productivity is one of the most important and serious problem in todays machine shops. The improvement of hole making production (drilling/reaming and tapping) has become a serious matter. One factor limiting productivity gains has been that conventional tool materials such as HSS exhibit very short tool lives when machining an aluminum alloy metal matrix composite (MMC) due to the abrasive nature of the SiC particles. Therefore, the improvement has been obstructed by various problems as rapid tool wear and failure. As a mean of achieving the desired productivity gains, forming taps have caught the attention of machine shop engineers. In this study, cutting characteristics of tapping (torque, taps wear, work hardness, etc.) during the tapping of MMC with forming taps, both TiN coated and uncoated was investigated. 2. Experimental Methods 2.1 Experimental Equipment The tapping tests were conducted on a Cincinati 5NC-MC (5HP). The (drilling and tapping) apparatus and data acquisition system are presented in Figure 2.1. The cutting forces (thrust and torque) were measured using a three component Kistler Type 9273 Piezo-electric dynamometer and the corresponding locus was amplified by a Kistler type 5007 charge amplifier. The signal obtained was then passed to a Towa A/D converter type AZI-16-12, connected to a personal computer. A schematic diagram of the cutting force measuring setup is presented in Figure 2.2. nts中国地质大学长城学院毕业设计 8 2.2 Workpiece, Drill and Tap The workpiece used in this experiment is aluminum alloy (2618 MMC) reinforced with 15 vol% silicon carbide (SiC) particulate. The thread forming fluteless taps were M10 as shown in Figure 2.3 and two types of taps were used during the course of the investigation. The shape of the taps was similar to the shape of a screw (M10, Pitch:1.5), either uncoated or coated with Titanium nitride (TiN). Pilot holes of 9.3mm diameter were used for all trials and PCD tipped drills (HSS cemented tungsten carbide and polycrystalline diamond drilling) were employed in all the tests. The shape of drill used in this test is shown in Figure 2.4. 2.3 Gauge and Inspection Method of Thread The estimate of threads was performed with a thread gauge (Go-NoGo gauge).The results were classified as A and B quality1. Where, 1.4tapped diameter is Diameter is the recommended depth of thread of hard Aluminum alloy2. A quality : Gauge can be turned through the whole thread. B quality : Gauge can be turned in at least 15mm. Figure 2.5 shows the appearance of gauge (M101.5 ISO 6H). nts中国地质大学长城学院毕业设计 9 2.4 Experimental Characteristics Tapping tests were conducted at a cutting speed (rotational speed of tap) of 215 rpm and feed rate of 0.1mm/rev (322.5mm/min). Coolant oil (Chlorine and sulphur free heat cutting oil) was supplied manually. 3. Experimental Results And Discussion Cutting Forces in Tapping (thrust, torque) The thrust and torque signals produced in this tapping operation with a M10 tap are shown in Figure 3.1. The results show that torque increases with number of threads formed and decreases at the instant that the tap is about to break through the outlet of the hole. Whereas, little increase in thrust can be observed. nts中国地质大学长城学院毕业设计 10 3.1 Comparison of Torque Figure 3.2 shows torque signals of tap in the 1st hole and 8th holes for the TiN-coated and uncoated taps mentioned in the previous section. At the initial stage of the tapping operation both thrust and torque show an increase in magnitude. However, when the thread forming operation enters full gear, the thrust force shows a decreasing trend accompanied with in increase in torque and as the tap retracts after breakthrough, a negative torque of 5N magnitude can be observed across a few threads at hole outlet. The negative thrust value observed in Figure 3.1 is the outcome of the deflection of the tap from the center due to either improper workpiece, tool setup or poor finish of the pilot holes. The inconclusive results observed above led to the investigating of the factors responsible for the poor finish of the pilot holes. The torque signals derived while threading taps for the 1st hole show tapping torque values of 8.7 Nm for the TiN coated tap and11.2 Nm for the uncoated and tap respectively. Thus, for the 1st hole, the TiN coated tap exhibits a 28% reduction in torque compared to the uncoated tap. While for the 8th hole the reduction in torque for the TiN coated tap is approximately 52% as compared to uncoated tap. Comparison of the torque signals at the initial phase and prior to breakthrough of the taps shows that the uncoated tap exhibits a sharper decrease in torque than the TiN coated tap. It can be said that, in the case of forming taps, work is evenly distributed at the scrape point during threading. A comparison of the torque results is summarized in Figure 3.3. Results indicate that tapping torque of the TiN coated tap is generally lower than those of the un-coated tap. 3.2 Comparison of Thread Forms The thread forms for the TiN coated and uncoated taps are shown in Figure 3.4. Magnified images of the axial cross-section of the formed threads at position No. , and in holes nts中国地质大学长城学院毕业设计 11 and 1.4 and 8 were used in the comparison. Figure 3.4 is a model of the photographed threads at the various positions, while Figure 3.5 shows magnified images for hole No.8 As it can be seen from Figure 3.5, the thread profile at position No. to of threads formed with the TiN coated tap show no abnormalities. On the contrary, with the uncoatedtaps the root shows irregularities at position No. and corresponding to the hole inlet and outlet. In order to validate the observations mentioned above, a detailed analysis was performed on holes No. and . Results are summarized in Figure 3.6. Figure 3.6(a) and (b) give results for hole No. and 8 at thread position No. and respectively. As it can be observed in Figure 3.6(a), the tooth profile of the TiN coated is far superior to the uncoated tap. 3.3 Comparison of Work Hardening A comparative study was performed to investigate the magnitude of work hardening when using the TiN coated and uncoated taps to form threads. Results of this study are summarized in Figure 3.7. Tap No.1 of both tap types were used. nts中国地质大学长城学院毕业设计 12 Results for the TiN coated and uncoated tap are given in Figure 3.7(a) and (b) respectively. Hardness was measured on a hardness tester loaded with a 100 gw. The results show that the hardness of the TiN coated tapping thread is lower than the uncoated tapping thread. The above results show that the TiN coated tap is superior to the uncoated tap in the following aspects, thread form and work hardening etc,. 3.4Comparison of Tool Life The TiN coated and uncoated taps were used to investigate the performance level with respect to tool life of taps. Tests were repeatedly performed three times with each type of tap. The results are summarized in Figure 3.8. Thread gauge readings were evaluated using A, B values. The results indicate that the average number of thread holes before tool life limit is reached are uncoated X =13 and TiN coated tap X =49 hole tap. The tool life of the TiN coated tap is 3.8 times longer than that of uncoated tap. nts中国地质大学长城学院毕业设计 13 3.5 Comparison of Tap Wear Figure 3.9 shows the tool wear of the various taps after threading in the experiments indicated in Figure 3.8. It should be noted that all the taps used for this comparison have already attained full tool life. TiN coated and uncoated taps are shown in Figure 3.9(a) and (b), respectively. It can be seen that the point of all the taps show tool wear. In addition, extensive wear can be observed at the boundary between the full thread form with the chamfer thread run-out of same 3 5 threads from the scrape point. A comparison of the TiN coated and the uncoated tap, as exemplified by the magnified point, shows that wear of the latter is more pronounced than the former. In the case of the TiN coated tap, an overlay of TiN coating can be observed at the tool wear zone. 4. Conclusions 4.1The tool life of the TiN coated tap was approximately 4 times longer than that of the uncoated tap. 4.2The TiN coated tap (for the 1st hole) exhibits 28% reduction in torque compared to the uncoated tap. 4.3The tooth profile of the thread produced by the TiN coated tap shows fewer irregularities than for the uncoated tap. 4.4 The hardness of the TiN coated tapping thread is lower than the uncoated tapping thread. 4.5From the above results, the TiN coated tap is superior to the uncoated tap in the following aspects, tool life, thread forms and work hardening etc,. References 1 WOLFGANGSTRACHE : Alternative Strategies for the Production of Threads in Aluminum-based SIC Reinforced Metal Matrix Composite (MMC) Alloy,1993. 2 Beitz.W : Dubbel-Taschhenbuch fuer den Maschinenbau. ISBN 3-540-52381-

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号