!【详情如下】CAD图纸+word设计说明书.doc[16000字,68页]【需要咨询购买全套设计请加QQ97666224】.bat

口环.dwg

叶轮.dwg

叶轮螺母.dwg

泵体.dwg

泵的概述及译文

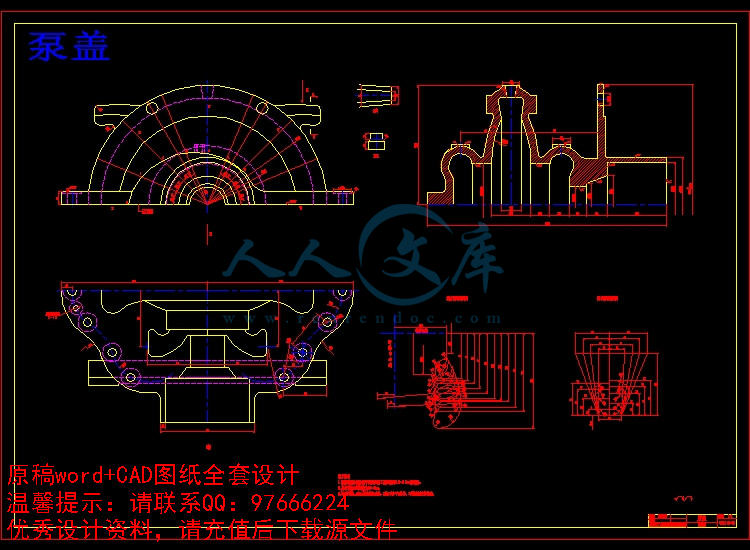

泵盖.dwg

泵装配图.dwg

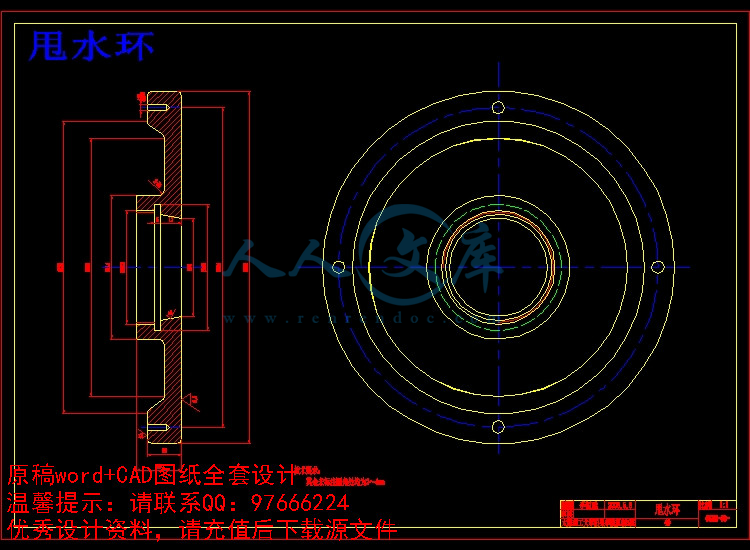

甩水环.dwg

设计任务书.doc

说明书.doc

说明书前几页.doc

说明书目录.doc

说明书附图

轴.dwg

轴套.dwg

连接法兰.dwg

摘要

泵是应用非常广泛的通用机械,可以说是液体流动之处,几乎都有泵在工作。而且,随着科学技术的发展,泵的应用领域正在迅速扩大,根据国家统计,泵的耗电量都约占全国总发电量的1/5,可见泵是当然的耗能大户。因而,提高泵技术水平对节约能耗具有重要意义。 6SHZ—60型水泵是清水泵,在设计问题上,从电机的选择计算、轴的选择计算、叶轮的尺寸以及水泵的外形尺寸的确定,基本上解决了泵的大体结构,在其它部件中,连接法兰、叶轮螺母等都是根据具体位置来计算设计的。传动中的轴、键、泵盖都要经过必需的校核,使它的强度和寿命达到设计要求。

关键词:水泵 电机 设计

Abstract

Pump is the most widely used general machinery,it can be said that any liquid flows,almost all of the pumps work,With the development of science and technology, pumping application areas are expanding rapidly,According to national statistics.Pump power consumption accounted for a fifth of the country,we can see that the pump is only natural consumption market.Pump technology will increase the level of energy conservation has a very important significance.6SHZ-60 is a water pump,the design issues,from motor choices,the choices of axis,the size of impeller pumps dimensions identification,

Largely determine the general structure pump. In other parts, the connecting flanges, Impeller nuts,etc.Are based on the specific location to calculate design.The drive shaft,bond,

Pumps are to be built after the necessary verification,so that their strength and life to the design requirements.

Key word:Water pump;Electrical machinery;Design

目录

摘要···················································

Abstract···················································

前言···················································

第一章 离心泵的工作原理··································

第二章 水泵的设计·········································

一.泵汽蚀余量的计算方法···································

二.泵的基本参数的确定····································

(一).确定泵的进口直径·····································

(二).确定泵的出口直径····································

(三).泵转速的确定········································

(四).估算泵的效率········································

(五).轴功率和原动机功率··································

第三章 水泵轴的设计········································

一.轴按外伸梁设计········································

二.轴按悬臂梁设计········································

第四章 叶轮结构设计及主要尺寸计算·······················

一.结构设计········································

二.叶轮结构型式的确定··································

三.叶轮轮毂直径的计算·································

四.叶轮进口直径的计算·································

五.叶轮外径的计算··········································

六.叶轮出口宽度的计算·································

七.叶片数的计算和选择·································

八.精算叶轮外径(第一次)·································

九.精算叶轮外径(第二次)·································

十.叶轮出口速度··········································

十一.叶轮进口速度··········································

第五章 压出室和吸入室的水力设计··························

一.压出室的水力设计········································

二.吸入室的水力设计········································

第六章 水泵零件的强度计算·································

一.泵体强度计算············································

(一)壳体壁厚·············································

(二)强度校核·············································

二.泵体法兰强度计算·······································

三.键的强度校核·········································

(一)叶轮与轴相连处的键····································

(二)电动机轴与叶轮轴相连处的键····························

四.叶轮强度计算··········································

(一)盖板强度计算·········································

(二)叶片厚度计算········································

(三)轮毂强度计算········································

五.泵体连接螺栓的强度计算·································

(一)计算密封力········································

(二)计算螺栓欲紧力和总作用力···························

(三)强度校核········································

六.泵出口法兰的强度校核···································

七.连接螺栓和连接法兰的强度校核···························

(一)连接螺栓的强度校核···································

(二)连接法兰的强度计算··································

第七章 泵的轴封设计计算··································

(一)密封端面间液体压力分布规律···························

(二)载荷系数和平衡系数··································

结论·····················································

参考文献·················································

外文资料·················································

中文翻译·················································

致谢·····················································

前言

毕业设计是对学生在毕业前所进行的一次综合能力的训练,是为给社会培养出合格的工程技术人员必须走过的重要环节。通过这次的毕业设计可以充分提高我们在以前所学的零散的理论知识的基础上结合起来综合的分析问题、解决问题的能力,这对我们上了岗位有很大的帮助。

我们这次的设计任务是6SHZ—60型的直联式双吸离心泵的基础的设计,是一次专题性的设计,虽然与四年所学知识有一定的偏距,但是为了能把这次的设计搞好,在赵老师的指导下,我们在设计前努力查阅有关资料,做了必要的准备,我们边设计边查阅资料,给设计奠定了一定的基础,这对我们的设计有很大的帮助。

这次设计集中于画图和水泵各部件的设计计算,我们先把指导老师所给的资料中的图纸吃透,独立分析问题,相互探讨并且解决问题,充分体现了我们独立解决问题的能力。

我们应该从现在做起学好扎实的基础知识,不断丰富自己的专业知识和实际操作能力, 这次设计,赵老师对我们进行了精心的指导,阳泉市水泵厂给了大力的支持并提供了有关资料,在此表示感谢,由于我们能力有限,在设计中难免有错误和不足之处。在此,请各位老师给于评定并提出建议。

第一章 离心泵的工作原理

泵是把原动机的机械能转换成液体能量的机器。泵用来增加液体的位能、压能、动能.原动机通过泵轴带动叶轮旋转,对液体做功,使其能量增加,从而使需要数量的液体,由吸水池经泵的过流部件输送到要求的高度或要求压力的地方。

如下图所示,是简单的离心泵装置。原动机带动叶轮旋转,将水从A处吸入泵内,排送到B处。泵中起主导作用的是叶轮,叶轮中的叶片强迫液体旋转,液体在离心力作用下向四周甩出。这种情况和转动的雨伞上的水滴向四周甩出去的道理一样。泵内的液体甩出去后,新的液体在大气压力下进入泵内,如此连续不断地从A处向B处供水。泵在开动前,应先灌满水。如不灌满水,叶轮只能带动空气旋转,因空气的单位体积的质量很小,产生的离心力甚小,无力把泵内和排水管路中的空气排出,不能在泵内造成一定的真空,水也就吸不上来。泵的底阀是为灌水用的,泵出口侧的调节阀是用来调节流量的。

川公网安备: 51019002004831号

川公网安备: 51019002004831号