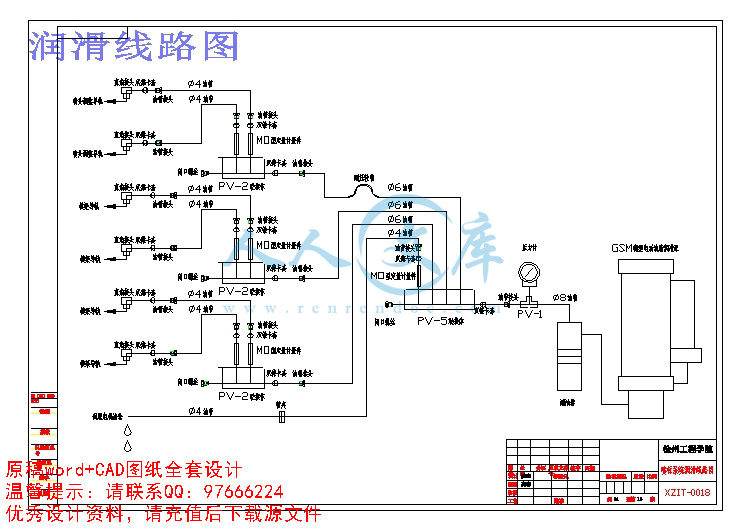

!【详情如下】CAD图纸+word设计说明书.doc[24000字,62页]【需要咨询购买全套设计请加QQ97666224】.bat

丝杆.dwg

丝杆座.dwg

任务书.doc

冲头.dwg

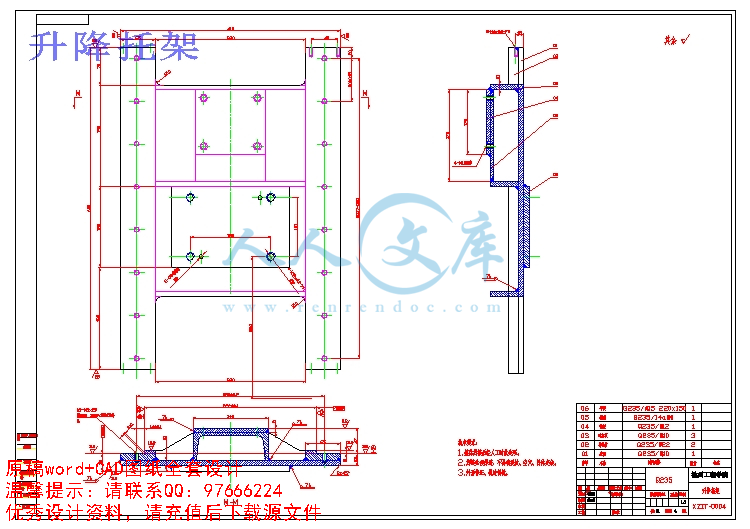

升降托架.dwg

喷标小车装配图.dwg

喷标流程图.dwg

喷标系统总装配图.dwg

外文翻译--机械运动和动力学.doc

大锥齿轮.dwg

小锥齿轮.dwg

手柄轴.dwg

摩擦盘.dwg

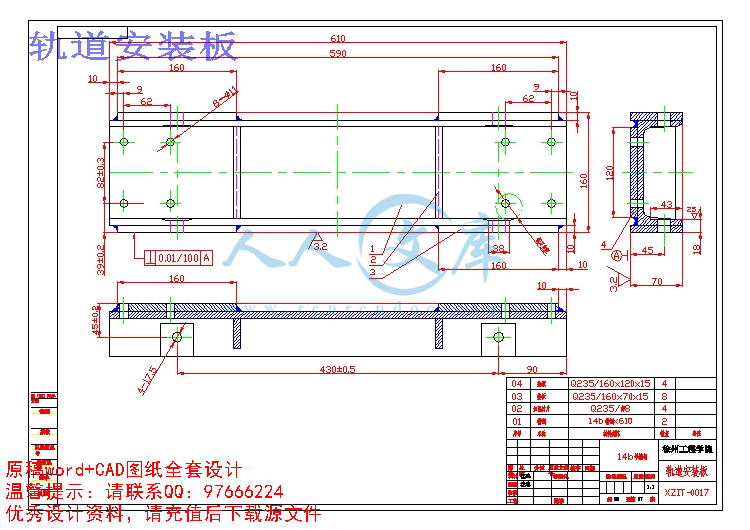

气缸固定座.dwg

气路图.dwg

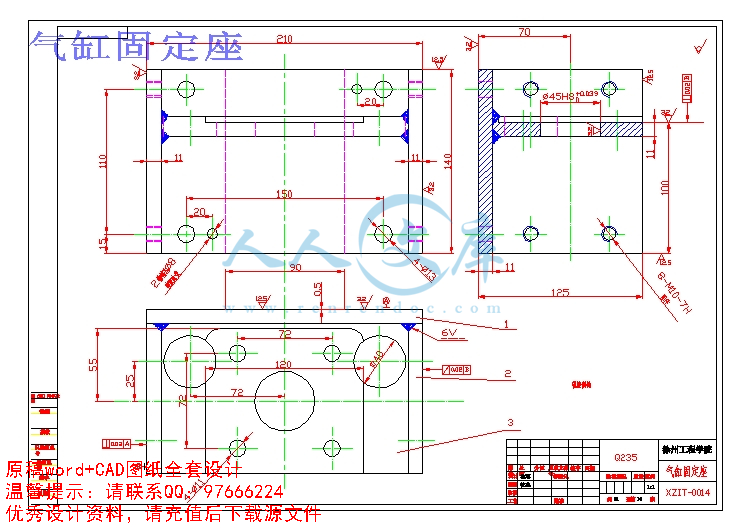

润滑线路图.dwg

电机角铁.dwg

移动支架.dwg

螺套.dwg

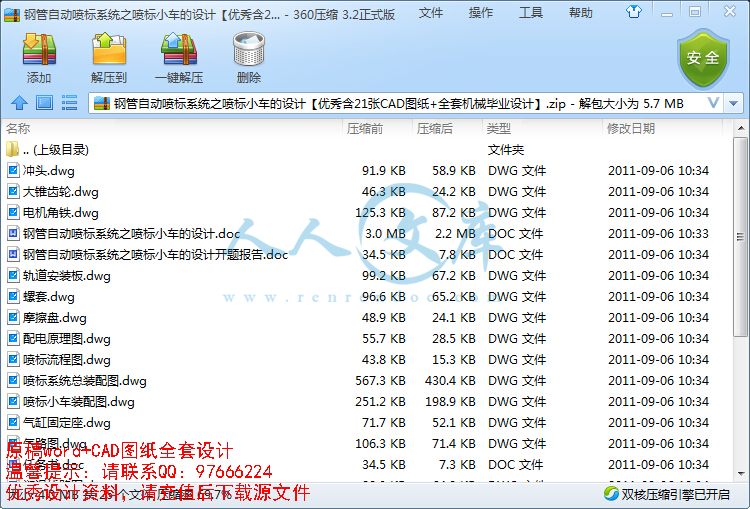

轨道安装板.dwg

轴承座.dwg

配电原理图.dwg

钢管自动喷标系统之喷标小车的设计.doc

钢管自动喷标系统之喷标小车的设计【优秀含21张CAD图纸+全套机械毕业设计】.zip

钢管自动喷标系统之喷标小车的设计开题报告.doc

铜螺母.dwg

摘要

钢管是一种多功能的钢材,其用途覆盖了石油、冶金、煤炭、汽车、船舶、电站以及军工等行业,为国家经济建设和国防安全做出了巨大的贡献。本文以国内外钢管生产线上精整区喷标系统的研究与开发现状为背景,对悬臂式钢管喷标系统进行了研究设计。本课题的主要研究工作:

第一章综合叙述了钢管的工艺生产流程及API国际标准;说明了国内喷标系统的开发现状及存在的问题并阐述了开发钢管喷标系统的必要性;陈述了课题的来源以及论文的主要工作和意义。

第二章针对喷标系统设计的总体说明,提出了系统的设计总目标;给出了系统设计的关键参数并给出了系统的平面布置图;根据系统的整体组成结构,对各部分机构及工作过程进行简单说明;最后给出喷标小车机械部分的设计方案以及简要概述喷标控制系统的总体设计。

第三章根据设备运行的要求设计了喷标小车的机械、电气结构,并且对关键部分的设计进行分析。

第四章介绍了喷标控制系统的设计组成,简述了PLC的编程方式,西门子S7400PLC的特点;PLC技术在工业应用中的优势分析以及PLC的硬件设计要求,喷标小车的伺服运动控制原理,最后给出了喷标流程图和相应的PLC程序。

第五章总结喷标系统设计过程所做的工作,并对系统的改进方向进行了展望。

关键词 钢管;喷标;PLC;伺服电机;位置控制

ABSTRACT

Steel tube is widely used as a sort of metallic material in oil,metallurgy,automobile, watercraft, electric plant, war industry and so on. It is important to the national economic development. This dissertation is based on the design and development of the system of steel tencil in home and abroad.with the aim of designing a Cantilever-Stencil Machine for Steel Pipe. the main contents are shown as follows:

In chapter 1,technological process of steel tube and the international standard API are introduced.Then the current situation of research and problems on tencilling system in China are described.And also,the necessities of the improvement of it are explained.Finally,the source of this project and the main contents as well as the significance of this paper are mentioned.

In chapter 2,according to the design target of stencil system,some key design parameters as well as the manufacture flow are put forward.The framework of an integrated tencil system comprising structures is presented,followed by a description of the mechanical struction and interaction.

In chapter 3, the mechanism structure is designed according to the requirement of the equipment function. And the pivotal piece is analyzed.

In chapter 4,PLC program metheod and the characters of S7400 series are introduced in brief.Attention are mainly focused on the modular design of PLC program,the servo-controlling system of the moving structure.flowed by the PLC program is mentioned.

In chapter 5,the work of dissertation is summarized and prospect of improving direction of system is presented.

Key words steel tube stencil PLC servo motor position control

目 录

1 绪论1

1.1 钢管喷标系统的开发现状1

1.1.1 引言1

1.1.2 喷标系统的开发现状3

1.2 钢管喷标系统开发的必要性4

1.3 课题来源4

1.4 论文的主要工作和意义4

2 喷标系统总体设计5

2.1 喷标系统设计要求5

2.2 喷标系统总体设计5

2.2.1 喷标小车的机械结构设计5

2.3 喷标系统的控制系统设计7

2.3.1 喷标系统的自动工作过程7

2.4 本章小结8

3 小车机械、电气结构设计9

3.1 横移机构的设计9

3.1.1 齿轮齿条副设计9

3.1.2 滚动直线导轨副设计10

3.1.3 伺服电机的选型14

3.2 喷头升降机构的设计15

3.2.1 选择喷标方式16

3.2.2 气缸的选型18

3.2.3 气缸活塞与喷头的配合18

3.2.4 气缸的固定19

3.3 喷头位置调节机构设计20

3.3.1 滚动直线导轨副21

3.3.2 锥齿轮副设计21

3.3.3 丝杆副设计29

3.4 防撞机构设计29

3.4.1 动作方式30

3.5 气路控制系统设计30

3.5.1 气动回路30

3.6 本章小结32

4 喷标控制系统设计33

4.1 控制系统的组成33

4.2 PLC软件及编程33

4.3 PLC在喷标系统中的应用34

4.3.1 PLC的特点34

4.3.2 PLC在工业应用中的优势34

4.3.3 S7-400编程方式35

4.4 PLC系统的硬件设计36

4.4.1PLC I/O点数统计36

4.5 喷标小车的伺服运动控制37

4.5.1伺服控制系统简介37

4.5.2 伺服运动控制系统工作原理38

4.6 PLC程序设计39

4.6.1 喷标流程39

4.7 配电电气控制40

4.8 本章小结40

5 结论41

致谢42

参考文献43

附录44

附录144

外文原文44

译文部分49

附录254

附录365

1 绪论

1.1 钢管喷标系统的开发现状

1.1.1 引言

钢管是一种用钢制作的具有中空截面而长度远大于外径(或边长)的金属材料。截面通常为圆形,但也可呈扁、方和异型等。钢管的结构特征是:

1)具有封闭的环形横断面;

2)两端开口;

3)管长与外径之比L/D较大;

钢管是一种多功能的经济断面钢材。它在国民经济各部门中的应用愈来愈广泛。

钢管作为输送管广泛地用于输送油、气、水等各种液体,如石油及天然气的钻探开采与输送、锅炉的水与蒸汽管道、一般的水煤气管道等。

钢管作为结构管大量地用于机械制造业和建筑工业,如用于制作房架、塔吊、钢管桩、各种车辆的构架等。在断面面积相同的条件下,钢管比圆钢、方钢等的抗弯能力大,钢性好,其单位体积的重量轻。因此,钢管是一种抗弯能力较强的结构材料。

钢管还作为中空的零件毛坯用于制造滚动轴承、液压支柱、液压缸筒体、空心轴、花键套、螺母以及手表壳等,这既节约金属又节省加工工时。

钢管又是国防工业中的重要材料,如用于制造枪管、炮筒及其他武器。随着航空、火箭、导弹、原子能与宇宙空间技术等的发展,精密、薄壁、高强度等钢管的需求量正迅速增长。

钢管的种类繁多,生产过程复杂,生产设备也很庞大,大型企业一般采用自动化生产线来完成钢管生产的各个工艺流程,一般热轧钢管的生产工艺如下图1-1所示。

参考文献

[1] 梁剑新.基于现场总线的自动喷号机的研制[D].浙江:浙江大学硕士学位论文,2001 .2

[2] 魏爱玉. 钢管MWBPS系统设计及控制软件的开发[D].浙江:浙江大学硕士学位论文,2004.2

[3] 姜晓勇.钢管测长、称重、喷标系统的研究与开发[D].浙江:浙江大学硕士学位论文,2003. 1

[4] 施江肖.WMBPS系统软件设计及测试策略研究[D].浙江:浙江大学硕士学位论文,2003. 1

[5] 唐志峰,项占琴,李明范等.点阵式自动钢管喷标机的研制[J].工程设计,2002

[6] 王彤.机电领域中伺服电机的选择原则[J].应用科技,2001(1)

[7] 西门子.SIMATIC S7梯形图编程手册[M],1998

[8] Steve Teixera,Xavier Pachcco. Delphi5开发人员指南[M].北京:机械工出版社,2001

[9] 蒋方炎.PLC在工业集散控制系统中的应用[J].电子计算机与外部设备,2000

[10] H-D.Chu and Dobson,Govement Report,PB97-176671,USA,1997

[11] Alan Kilian. Quick and Easy Motor Control, CIRCUIT CELLAR. 2001, 7

[12] Wai, R.-J.; Lee, M.-C.; Intelligent Optimal Control of Single-Link Flexible

Robot Arm, Industrial Electronics, IEEE Transactions on,Volume: 51,Issue:1,Feb. 2004 Pages:201一220

[13] 郭庆鼎,王成元.交流伺服系统[M].北京:机械工业出版社,1993. 6

[14] 沈安文.位置控制系统中电子齿轮实现的简易方法[J].机械与电子,2001

[15] 孙克梅,田中大,王俊.喷绘机位置控制系统设计[M].控制工程,2003. 3

[16] 姚晓光,余强等.微机监控系统中PLC与上位机通信的研究[J].电气自动化,1999. 4

[17] 蔡忠法等.上下位机数据通信的模块化接口技术及应用[J].微计算机信息,2002. 2

[18] 黄锡恺,郑文纬.机械原理[M].北京:高等教育出版社,1989

[19] 濮良贵,纪名刚.机械设计[M].北京:高等教育出版社,1996

[20] 秦曾煌.电工技术[M].北京:高等教育出版社,1993

[21] 宋红晓,项占琴.龙门式钢管喷标机的研制[J].机电一体化技术,2005.7

[22] 罗福兴.龙门式喷标机的研发[D].浙江:浙江大学硕士学位论文,20004.2

[23] OMRON中国有限公司.接近传感器以及光电传感器选型手册[M],2002

[24] 《电气工程师手册》第二版编辑委员会.《电气工程师手册》第二版[M].北京:机械工业出版社,2002.1

[25] 《现代机械传动手册》编辑委员会.《现代机械传动手册》第二版[M].北京:机械工业出版社,2002.3

[26] 《机械设计手册》编委会.《机械设计手册》第三版第2卷[M].北京机械工业出版社,2004.8

[27] 《机械设计手册》编委会.机械设计手册(单行本)零部件设计常用基础标准[M].北京:机械工业出版社,2004.8

[28] 左键民.液压与气压传动[M].北京:机械工业出版社,2005,7

[29] 范思冲.画法几何及机械制图[M].北京:机械工业出版社,2005.9

川公网安备: 51019002004831号

川公网安备: 51019002004831号