!【详情如下】CAD图纸+word设计说明书.doc[35000字,79页]【需要咨询购买全套设计请加QQ97666224】.bat

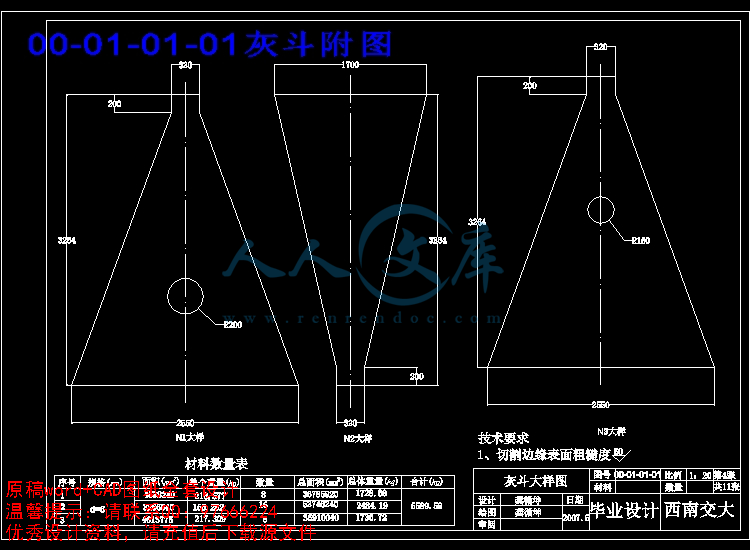

00-01-01-01灰斗附图.dwg

00-01-01灰斗.dwg

00-01-02-01卸灰阀附图.dwg

00-01-02卸灰阀.dwg

00-01除尘器.dwg

00-02-01-01冷却塔灰斗.dwg

00-02-01冷却塔灰斗.dwg

00-02-02-01冷却塔集气罩.dwg

00-02-02冷却塔集气罩.dwg

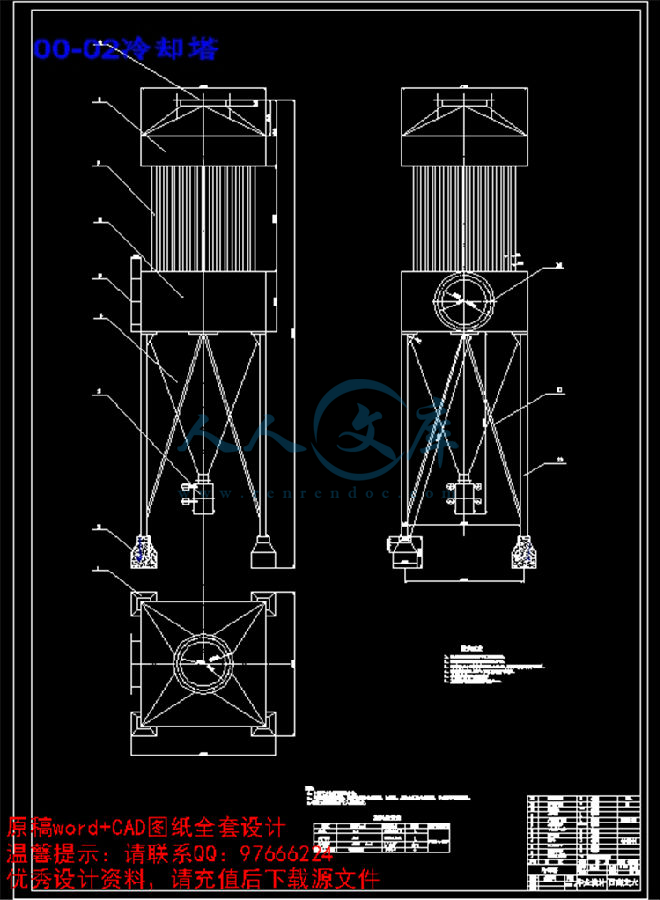

00-02冷却塔.dwg

00总体装置图.dwg

环保钢结构的设计与制造.doc

环保钢结构设计与制造.ppt

英文翻译

设计说明书.doc[35000字,79页]

毕业设计(论文)任务书

题 目 环保钢结构的设计与制造——袋式除尘器

1、本论文的目的、意义 随着工业的高速发展,环境污染日益严重,在人们生活水平不断提高的同时,对生活环境的质量要求也越来越高。特别在环境保护工作日益突出的今天,伴随着我国钢铁需求量的不断增加,针对冶金工业设计除尘器。对烟气进行综合治理,改善周边环境。加强对环境的保护,同时又能将从烟尘中带走的各种金属进行回收利用,特别是一些贵重的金属和稀有金属。起到了节约资源的作用。此题目的选择具的重要的意义。

2、学生应完成的任务

1)完成A0当量图纸大于3张,

2)设计说明书1份

3)英文翻译大于10000字符

4)论文日志

5)设计论文光盘一个

内容包括:1.文献综述

2.结构计算与校核

3.方案的选择与制定

4.计算结果

5.成本核算

3、论文各部分内容及时间分配:(共 15 周)

第一部分 查阅文献及调研 (2周)

第二部分 设计方案制定,并进行相关的计算校核 (8周)

第三部分 绘制设备结构与相关制造大样图 (2周)

第四部分 论文书写 (1周)

第五部分(1周)

评阅及答辩(1周)

摘 要

在冶金过程中,产生大量的废气,这些废气的含尘浓度高,烟尘的危害性大,对环境造成严重的污染。同时,这些烟尘又有一定的回收和利用价值。因此,治理这些烟尘具有显著的经济效益和社会效益。

本设计针对冶炼的生产及场地等的具体情况,来设计布袋除尘器,并且使其排污情况达到国家相关的排放标准要求。而且,又要尽量满足投资少、运转费用低、操作方便、维护简单的要求。

目前,国内外除尘设备的种类和型号较多,通过对它们的原理的分析以及性能的比较等,根据实际情况, 选出了对冶金炉废气控制的最佳方案。选用袋式除尘器并进行了设计计算确定了布袋的型号、尺寸、根数 ,对除尘器外部箱体、支架和灰斗等钢结构部件也进行了设计,并计算了其重量和面积和列出材料的数量表。然后对除尘系统 进行长效防腐设计,根据现场,合理对各个部件进行了布局。

本设计选用的负压吸灰的袋式除尘器在原有除尘器的基础上,进行了一系列的改进。该除尘器节约成本, 扩大了除尘的效率,同时,冷却塔的设计,降低了含尘气体的温度,保证了除尘器内布袋使用寿命,并合 理地利用了空间,对除尘和清灰达到了全自动化控制。

在本设计中,不但完成了对除尘系统总体的设计,而且强化细节,做到了所设计的除尘系统可以直接进行 加工、安装、调试并投入使用。并对成本进行了投资预算.对所要的材料都进行了全部的统计。

关键词: 大气污染;袋式除尘器;钢结构;长效防腐

Abstract

In the process of metallurgy, a large amount of exhaust gas will be produced, which contains a high concentration of ash or dust. This kind of ash is very harmful and will pollute the environment. At the same time, the ash also has a value in reclamation and reuse. Therefore, it has a significant economic and social benefit to treat with it.

In this dpaper, according to the idiographic case of the producing and place etc. of smelting, it designs hop-pocket dust catcher and makes waste-excreting up to the relevant national standard criterion. What’s more, it should meet the requests of less investment, low running cost, conveniency for operation and easiness for maintenance as necessary as possible.

At present, there are relatively too many sorts and models of dust catcher at home and abroad, through the analyse of their theories and comparison of capability, according to the practical condition, we select the best scheme in calcium carbide furnace exhaust gas controlling. Having the hop-pocket dust catcher selected and the design calculation worked out, we fixed the model, size and root-number of the bag, and we have also designed the steel structure of the dust catcher’s several parts such as the exterior box, bracket and the ash- funnel etc. moreover, with its weight and area calculated. Then, towards the dust-removing system, we carried out the long-effective antisepticising design. According to the locale, we made a proper overall arrangement of each part, and checked on the economic and running cost at last.

This devise has a series of improvement. Compared with the original one,this hop-pocket dust catcher using a minus- pressure ash- absorbing technology. It will not only save the cost and enhance the dust-removing efficiency, because the design of cooling tower, it will also lower the temperature of the gas containing dust, in order to have the??? effective longevity of the bag guaranteed. Besides, the room can be used properly; the removing of dust and cleaning of ash are entirely automatically controlled.

In the paper, it has finished contriving the dust-removing system not only on the whole, furthermore, it has intensified the details of the device, so that it is able to carry out processing, installing, adjusting and been put in to effect directly. Moreover, the budget of investment and listed all the materials needed have worked out statistically.

keywords:air pollution, hop-pocket dust catcher, steel structure, long-effective antisepticising

目 录

第一章 绪论1

1.1环境保护与可持续发展1

1.1.1环境与环境问题1

1.1.2 可持续发展2

1.2对大气的结构及组成的认识3

1.2.1大气圈及其及结构3

1.2.2 大气污染物4

1.2.3 锅炉大气污染物排放标准6

1.2.4 污染与健康7

1.2.5 大气污染的综合防治8

1.3 任务的提出与意义10

1.3.1 设计要求以及基本参数10

1.3.2 设计内容包括10

1.3.3 选题的意义10

第二章 除尘设备的分类及其型号的选择11

2.1除尘设备的概述11

2.1.1 除尘器的概念11

2.1.2 除尘器的分类11

2.2 各种除尘器原理12

2.2.1 机械式除尘器12

2.2.2 静电除尘器19

2.2.3 湿式除尘器20

2.2.4袋式除尘器20

2.2.5 复合式除尘器26

2.2.6各种除尘器的性能比较及其型号的选择26

2.3 确定方案27

2.3.1滤袋速度的选择28

2.3.2 清灰方式的确定28

2.3.3 滤袋形式的确定31

2.3.4 过滤方向的确定31

2.3.5 进风口位置的选择31

2.3.7滤料的选择33

第三章 除尘器的设计与计算37

3.1参数的计算37

3.1.1 计算需要的过滤面积和袋室数目37

3.2 风机的选择43

3.2.1 风机性能的比较43

3.3 冷却塔的设计45

3.3.1 冷却方式的选择45

3.3.2 冷却塔主要参数的计算48

3.4 除尘器卸灰系统设计49

3.4.1 除尘器卸灰阀的设计49

3.5 除尘器的基础的设计50

3.6钢结构部分的设计50

3.7 屋架的设计51

3.8 房子主体结构设计51

第四章.施工及其焊接要求53

4.1施工要求53

4.2 环保钢结构手工电弧焊焊接施工53

4.2.1对焊接有关人员的要求53

4.2.2开坡口53

4.2.3质量要求53

4.2.4施工准备53

4.2.5 材料的关键要求55

4.2.6 作业条件55

4.2.7 质量关键要求55

4.3 工艺流程56

4.3.1工艺流程图56

4.4 安全保护措施56

4.5 环境保护措施57

4.6 质量记录58

第五章 除尘器的防腐与维护59

5.1防腐工艺的实施59

5.1.1高压空气的制备59

5.1.2工件喷砂处理59

第六章 成本核算及投资63

6.1工程建设投资核算63

6.1.1 除尘器本体部分建造投资63

6.2养护、维修投资核算65

6.2.1 电耗费用65

6.2.2 维修费用65

第七章 经济效益的评估66

结 论67

致 谢68

参考文献69

参考文献

[1] 钱易,唐孝炎主编.环境保护与可持续发展.北京:高等教育出版社,2000.

[2] 郭静,阮宜纶主编.大气污染控制工程.北京:化学工业出版社,2001.

[3] 黄学敏,张承中主编.大气污染控制工程实践教程.北京:化学工业出版社,2003.

[4] 陈明绍,吴光兴,张大中,王长跟编著.除尘技术的基本理论与应用.北京:中国建筑工业出版社,1981.

[5] 何争光主编.大气污染控制工程及应用实例.北京:化学工业出版社,2004.

[6] 蒋文举,宁平主编.大气污染控制工程.成都:四川大学出版社,2001.

[7] 李坚等主编.环境工程设计基础.北京:化学工业出版社,2002.

[8] 孙熙主编.袋式除尘技术与应用.北京:机械工业出版社,2004.

[9] 祝燮权主编.实用五金手册.上海:上海科学技术出版社,2001.

[10] 陈胜颐主编.钢结构设计手册.北京:轻业出版社,1990.

[11] 严兴忠主编.工业防尘手册.北京:劳动人事出版社出版,1989.

[12] 罗邦富,沈祖炎主编.钢结构设计手册.北京:中国建筑工业出版社,1989.

[13] 黄呈伟主编.钢结构设计.北京:科学出版社,2005.

[14] 张建勋编著.现代焊接生产与管理.北京:机械工业出版社,2006.

[15] 何铭新,钱可强主编. 机械制图.第四版. 北京.高等教育出版社,1997.

[16] 吴忠标主编.大气污染控制工程.北京:科学出版社,2002.

[17] 肖亚明主编. 建筑钢结构设计.合肥:合肥工业大学出版社,2006

[18] 王丽萍主编. 大气污染控制工程.北京.高等教育出版社,2002

[19] 李连山主编. 大气污染控制工程.北京.高等教育出版社.2003

[20] 徐世明,胡月华, 李卉, 张改芳. 反吹风布袋除尘器的应用.磷肥与复肥.

2000年第15卷第5期:P17

[21] 吴英浩. 升压风机在电厂烟气脱硫中的应用及选择. 云南电力技术.2004年11月第35期.

[22] 石增斌. 布袋除尘器技术及其应用. 煤炭技术.Vol 25(1),2006年:123-

[24] 李国厚,赵明富. 除尘器通用控制仪的设计. 金属矿山,2006年第3期:77

[24] 张瑞平,赵士骐,吴利勤. 布袋除尘器的应用及前景.煤气与电力.2004年7月第7期.

[25] 李志华. 袋式除尘器设计参数的确定.综述与专论.2004年.30卷P29

[26] 朱 健,马从生,陈永仕. JLDC立窑袋式除尘器的设计与应用. 水泥CNMENT

2004.NO.2:49

[27] 王 升,杨彦香. 环保设备用焊管的生产. 焊管,Vol25(4) 2002:33

[28]柴昶, 宋曼华主编.钢结构设计与计算(第二版).北京.机械工业出版社,2006.

川公网安备: 51019002004831号

川公网安备: 51019002004831号