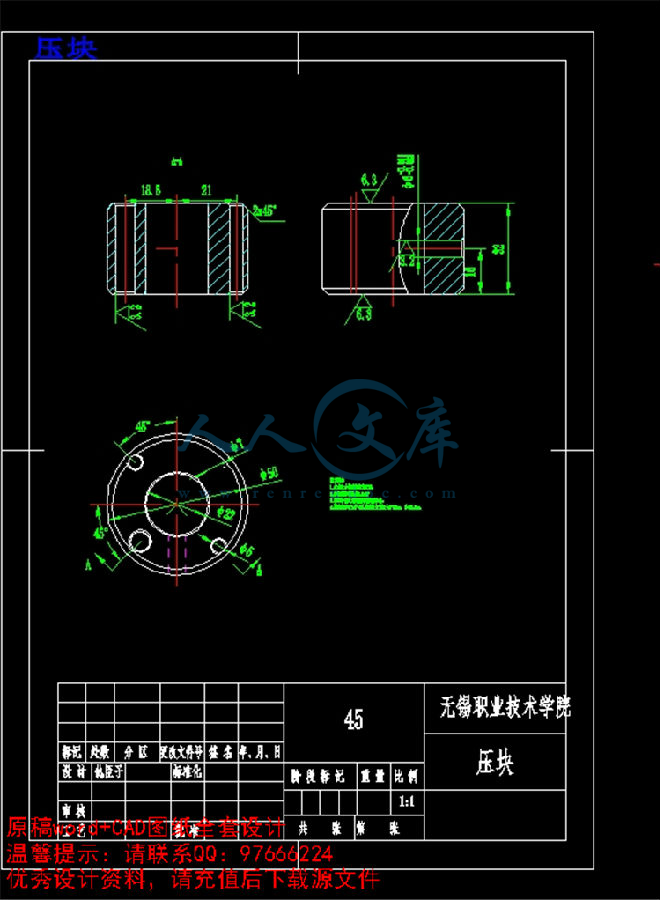

!【详情如下】CAD图纸+word设计说明书.doc[12000字,30页]【需要咨询购买全套设计请加QQ97666224】.bat

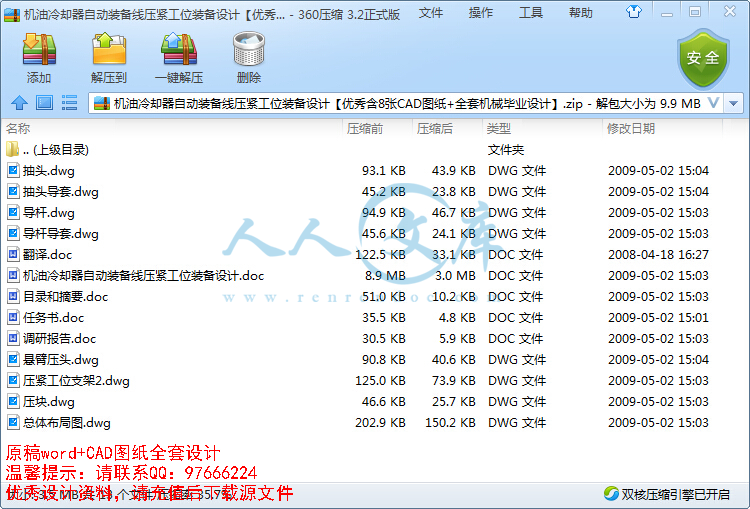

压块.dwg

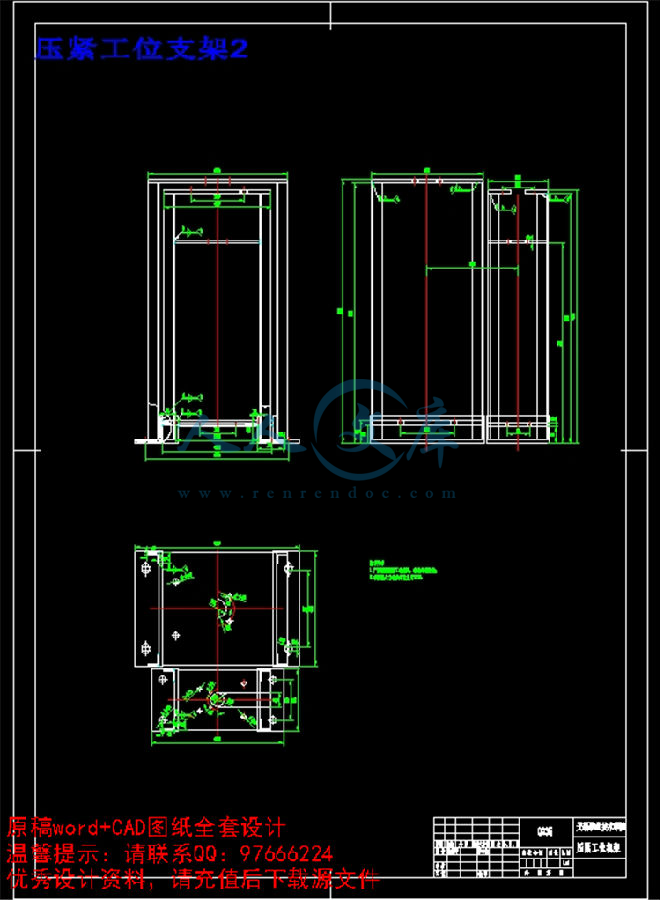

压紧工位支架2.dwg

导杆.dwg

导杆导套.dwg

总体布局图.dwg

悬臂压头.dwg

抽头.dwg

抽头导套.dwg

设计说明书.doc[12000字,30页]

目录和摘要.doc

翻译.doc

调研报告.doc

任务书.doc

目 录

第一章 引言1

1.1课题的来源、意义1

1.1.1课题的来源2

1.1.2 课题的意义2

第二章 总体方案设计3

2.1机油冷却器自动装配线的设计要求3

2.2装配方案设计3

2.2.1装配工艺分析与确定3

2.2.2装配线传送方案的比较与确定4

2.3 总体方案的确定5

第三章 压紧工位装备设计8

3.1机油冷却器定位方案的比较与确定8

3.2机油冷却器夹紧方案的比较与确定9

3.3抽头的设计12

3.4压力机的设计13

3.4.1方案设计13

3.4.2气缸的选择与设计13

压紧气缸的选择与设计13

抽头气缸的选择与设计17

旋转气缸的选择18

3.4.3压紧工位支架的设计19

3.4.4压力机压头的设计20

悬臂压杆的设计20

摆动支架的设计22

转块的设计23

压块的设计24

3.4.5导套的设计24

抽头导套的设计24

导杆导套的设计25

3.4.6气缸连接件的选用25

3.4.7夹紧工位结构的确定26

第四章 总 结27

致 谢28

参考文献29

摘 要

汽车发动机在高速旋转下发热量很大,尤其是大功率发动机,在高温下对汽车发动机润滑系统的可靠性要求比较高。而机油冷却器可以保持发动机工作状态下可靠的润滑。提高其工作可靠性和寿命,降低发动机本体的制造精度,对于车载发动机来说是必不可少的配套装置。随着我国现代化进程的加快,汽车工业的迅猛发展,机油冷却器市场中的需求越来越大,圆盘机油冷却器由于其结构及性能的优势,更是需求加大。

机油冷却器的装配工艺过程是其制造过程中非常重要的环节,装配质量的好坏直接影响机油冷却器的密封性能。可是,由于机油冷却器的结构特点限制,长期以来,在国内外这一工艺过程一直靠人手工操作,效率低,工作劳动强度大,且装配质量过多地受到人为因素的影响,致使机油冷却器质量的稳定性和可靠性不高。随着企业用户需求量的增加,扬州通洋机油冷却器有限公司准备建造一条针对不锈钢圆盘式机油冷却器的自动装配线。基于机油冷却器的结构特点限制,采用完全的自动装配是不现实的。因此在原来的手工装配线,开发一条半自动装配线符合该厂目前的实际情况。这既可以提高机油冷却器的装配质量,又可以节约大量成本。自动装配线由机械系统(包括装配输送线、装配机械手、定位装置、压紧设备等)、气压系统、电气系统和PLC控制系统等部分组成. 无疑它将是机、电、气一体化的产品。

关键词:机油冷却器,自动化装配线,压力机。

Abstract

Automobile engine in high-speed rotary would get heat. Under the high temperature, a car's engine lubrication system’s reliability requirements are relatively high, especially with high-power engine. And the oil cooler can maintain engine under reliable lubrication in work, improving their reliability and life expectancy, lowering precision of engine manufacturing. It is an essential supporting device for the truck engine. With the acceleration of the process of modernization and the rapid development of the auto industry, the demand of oil cooler market increases quickly, especially for disk-oil coolers, because of its advantages of structure and properties.

Oil cooler assembly process is a very important part in the manufacturing process. The assembly quality will do a direct impact on the oil cooler sealing performance. However, as the restrictions of the oil cooler of the structure, for a long time, the assembly process has relied on hand not only at home but also abroad. It is inefficient, labor-intensive. And assembly quality is mainly due to artificially ,this made the stability and reliability of oil cooler is not high.

An automatic assembling line for stainless steel flat-fin oil cooler has been planed to set up at Yangzhou Tongyang Oil Cooler Co., Ltd. However, due to its structure feature, it’s not realistic to set up the fully equipped automatic assembly line of oil cooler. So based on the original manual assembling line, building semiautomatic assembly line is a ideal method which accord with real situation with the this firm at present. It can not only improve the assembling quality of oil cooler, but also save a lot of money.

Automatic assembly line combines mechanical systems (including assembly line, assembly manipulator, positioning devices, compaction equipment, etc.), pressure systems, electrical systems and PLC control system. Obviously it is a composite product including machine, electricity, gas driving etc.

Keywords : oil cooler, automated assembly lines, press machine .

川公网安备: 51019002004831号

川公网安备: 51019002004831号