哈尔滨理工大学

哈理工大学机械制造工艺学设计任务书························4

序言· ····················································5

一、零件的分析··············································5

1.1左摆动杠杆的作用····································5

1.2左摆动杠杆的技术要求···································5

1.3左摆动杠杆的工艺分析·······························6

1.4确定左摆动杠杆的生产类型··························6

二、工艺规程设········································6

2.1确定毛坯的制造形式·····································7

2.2确定毛坯的尺寸公差和机械加工余量·······················7

2.2.1公差等级········································7

2.2.2锻件重量········································7

2.2.3锻件形状复杂系数·································7

2.2.4锻件材质系数····································7

2.2.5零件表面粗糙度··································7

2.3定位基准的选择········································8

2.3.1精基准的选择··································· 8

2.3.2粗基准的选择·····································8

2.4表面加工方法的确定·····································9

2.5加工阶段的划分·········································9

2.6工序的集中与分散······································9

2.7工序顺序的安排········································10

2.7.1机械加工工序····································10

2.7.2热处理工序······································10

2.7.3辅助工序·······································10

2.8确定工艺路线··········································10

2.9 机械加工余量、工序尺寸及毛坯尺寸的确定··············12

2.9.1选择机床 根据不同的工序选择机床 ···············12

2.9.2选择夹具 ·····································12

2.9.3选择刀具 根据不同的工序选择刀具················13

2.10加工余量工序尺寸及公差的确定·························13

2.11 确定切削用量及基本工时····························16

2.11.1粗精铣宽24mm,毛坯28mm,的下表面·················16

2.11.2 孔的加工 ····································18

2.11.3 铣槽 ········································22

2.11.4时间定额的计算·································22

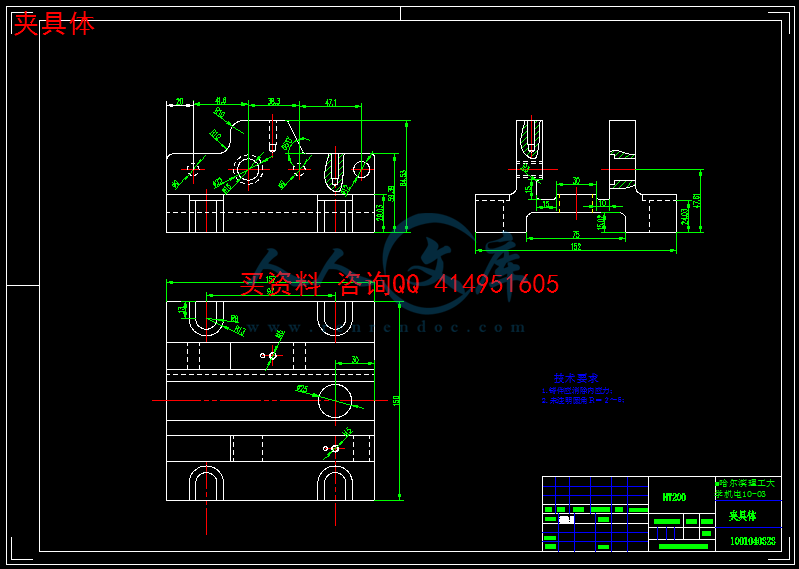

三、设计夹具···············································25

3.1、提出问题·········································26

3.2、设计思想··········································26

3.3、夹具设计·········································26

3.3.1、定位分析······································26

3.3.2、切削力及夹紧力的计算··························27

3.3.3、夹具操作说明··································28

3.3.4、确定导向装置··································28

四、体会与展望··············································29

五、参考资料················································30

哈理工大学

机械制造工艺学课程设计任务书

题目:设计“左摆动杠杆”零件的机械加工工艺规程及工艺装配(年产量为5000件)

内容: 1.零件图 一张

2.毛坯图 一张

3.机械加工工艺过程综合卡片 一张

4.结构设计装配图 一张

5.结构设计零件图 一张

6.课程设计说明书 一份

序言

机械制造工艺课程设计是我们学完了大学的全部基础课程、技术基础课程以及大部分专业课程之后进行的。这是我们在进行毕业设计之前所学课程的一次深入的综合性的总复习,也是一次理论联系实际的训练,因此,它在我们四年的生活里占有重要地位。

一、零件的分析

1.1左摆动杠杆的作用

杠杆原理亦称“杠杆平衡条件”。要使杠杆平衡,作用在杠杆上的两个力(用力点、支点和阻力点)的大小跟它们的力臂成反比。动力×动力臂=阻力×阻力臂,用代数式表示为

川公网安备: 51019002004831号

川公网安备: 51019002004831号