数控铣床回转工作台设计[全套CAD+说明书+开题报告等]

收藏

资源目录

压缩包内文档预览:(预览前20页/共26页)

编号:456904

类型:共享资源

大小:430.99KB

格式:RAR

上传时间:2015-07-15

上传人:小****

认证信息

个人认证

崔**(实名认证)

辽宁

IP属地:辽宁

15

积分

- 关 键 词:

-

数控

铣床

回转

工作台

设计

- 资源描述:

-

目 录

摘要

Abstract

绪论 1

第一章:数控回转工作台的原理与应用 2

1.1 数控回转工作的原理2

1.2 设计准则4

1.3 主要技术参数4

1.4 本章小结4

第二章:数控回转工作台的结构设计5

2.1 传动方案的确定5

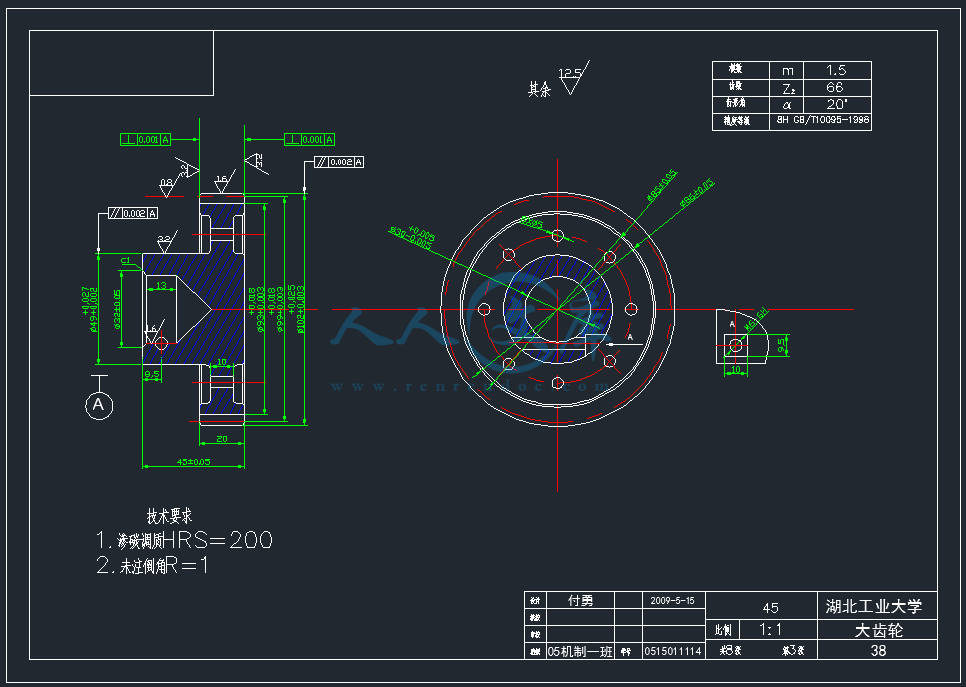

2.2 齿轮传动的设计7

2.3 电液脉冲马达的选择及运动参数的计算9

2.4 蜗轮及蜗杆的选用与校核11

2.5 蜗杆与蜗轮的主要参数与几何尺寸13

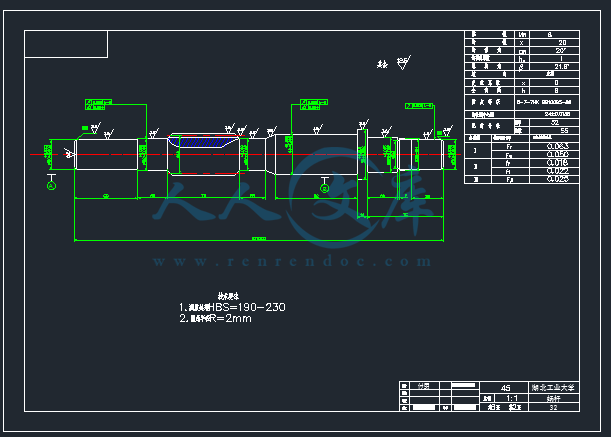

2.6 轴的校核与计算15

2.7 弯矩组合图17

2.8 齿轮上键的选择及校核17

2.9 轴承的选用17

2.10 本章小结19

第三章 数控技术发展趋势20

3.1 性能发展方向20

3.2 功能发展方向20

3.3 体系结构的发展21

3.4 智能化新一代PCNC数控系统22

第四章 总结 23

致谢 24

参考文献 25

摘 要

数控车床今后将向中高挡发展,中档采用普及型数控刀架配套,高档采用动力型刀架,兼有液压刀架、伺服刀架、立式刀架等品种,预计近年来对数控刀架需求量将大大增加。但是数控回转工作台更有发展前途,它是一种可以实现圆周进给和分度运动的工作台,它常被使用于卧式的镗床和加工中心上,可提高加工效率,完成更多的工艺,它主要由原动力、齿轮传动、蜗杆传动、工作台等部分组成,并可进行间隙消除和蜗轮加紧,是一种很实用的加工工具。本课题主要介绍了它的原理和机械结构的设计,并对以上部分运用AUTOCAD做图,最后是对数控回转工作台提出的一点建议。

关键词:数控回转工作台 齿轮传动 蜗杆传动 间隙消除 蜗轮加紧

- 内容简介:

-

附一: 毕业设计(论文) 档案袋内组成部分 一、毕业设计(论文)册内容与装订顺序: 封面; 论文题目不得超过 20 个字,要简练、准确,可分为两行。 内容 1、 毕业设计(论文)任务书; 任务书由指导教师填写,经 所在 系 部 审查签字后生效。 2、 毕业设计(论文)开题报告; 3、 毕业设计(论文)学生申请答辩表与指导教师毕业设计(论文)评审表; 4、 毕业设计(论文)评阅人评审表; 5、 毕业设计(论文)答辩表; 6、 毕业设计(论文)答辩记录表; 7、 毕业设计(论文)成绩评定总表; 8、论文: (1)中文题目与作者; (2)英文 题目与作者; (3)中文 内容摘要 和关键词; (4)英文内容摘要和关键词; (5)目录; (6)正文; (7)致谢; (8)参考文献及引用资料目录 ; (9)附录; (10)实验数据表 、有关图纸 (大于 3#图幅时单独装订 ); 封底。 二、 英文资料翻译册内容与装订顺序: 封面; 内容 1、英文原文; 2、中文翻译; 3、阅读书目 ; 封底。 nts 1 毕业设计(论文)任务书 系 部 机电工程系 指导教师 李兆铨 职 称 高工 学生姓名 付勇 专业班级 05gb 机制 1 学 号 0515011114 设计题目 数控回转工作台 设 计 内 容 目 标 和 要 求 数控回转工作台是数控机床的主要附件之一,主要用于数控铣床,数控镗床等。其外形和普通回转工作台相似,但其内部结构具有数 控进给驱动系统的许多特点,它的功能是使工作台实现圆周进给,并能进行分度。分析数控转台的结构特点,设计一个开环系统的回转工作台,它的传动系统应有消除间隙结构及蜗轮夹紧装置等。 . 一 .设计内容 1.测绘一个在数控铣床(或加工中心)上用数控转台加 工的典型零件,绘制零件工作图,工序图。 2.进行数控转台方案分析,台面直径为 400mm。绘制数控转台总装配图。 3.设计该转台的主要零部件,如壳体,转台,蜗轮。蜗杆,夹紧装置等,画出 4张以上零件的工作图。 4.撰写设计说明书 。 二 .设计要求 1.设计必须独立完成,要有创造性,不要照抄照搬实习现场的工艺,工装,设备等。 2.设计绘图工作总量一 般不少于 2.5A0,其中用计算机绘图不少于一张 A1,但是不超过总绘图量的一半。 3.说明书的内容应是围绕本人的设计的内容进行分析,计算和验证,对本回转工作台传动装置的消隙结构应有比较清楚的论述。不要抄书。说明书内容一般不少于 25 页。 4.其它有关事项按院,系有关规定执行。 三 .参考资料 1.吉林工大等主编 金属切削机床设计 机械工业出版社 2.金属切削机床设计手册 机械工业出版社 3.大连组合机床所编 组合机床设计手册 机械工业出版社 4.上海纺织工学院等主编 金属切削机床图册 上海科技出版社 nts 指导教师签名: 年 月 日 系 部审 核 此表由指导教师填写 由所在系部 审核 nts 2-1 毕业设计(论文)学生开题报告 课题名称 数控回转工作台 课题来源 生产实践 课题类型 AY 指导教师 李兆铨 学生姓名 付 勇 学 号 0515011114 专业班级 05gb 机制 1 本课题的研究现状,研究目的及意义 数控回转工作台是数控机床的主要附件之一,主要用于数控铣床,数控镗床等。其外形和普通回转工作台相似,但其内部结构具有数 控进给驱动系统的许多特点,它的功能是使工作台实现圆周进给,并能进行分度。分析数控转台的结构特点,设计一个开环系统的回转工作台,它的传动系统应有消除间隙结构及蜗轮夹紧装置等。 课题类型: ( 1) A 工程实践型 ; B 理论研究型 ; C 科研装置研制型 ; D 计算机软件型 ; E 综合应用型 ( 2) X 真实课题; Y 模拟课题; ( 1)、( 2)均要填,如 AY、 BX 等。 nts 2-2 本课题研究的内容 1.测绘一个在数控铣床( 或加工中心)上用数控转台加工的典型零件,绘制零件工。 作图,工序图 2.进行数控转台方案分析,台面直径为 400mm。绘制数控转台总装配图。 3.设 计该转台的主要零部件,如壳体,转台,蜗轮。蜗杆,夹紧装置等,画出 4 张 以上零件的工作图。 4.撰写设计说明书。 本课题的实施方案 ,进度安排 查阅资料 了解回转工作台工作原理 联系实际 了 解定位及夹紧机构、分度机构的组成、工作原理及特点 进行多种设计方案的比较 完成回转工作台的总体设计 3.16-3.20 发任务书 ,收集资料 ,写开题报告 . 3.23-3.27 完成开题报告 3.30-4.17 制定设计方案 4.20-5.15 绘制设计图纸 5.18-5.24 撰写设计说明书 6.1-6.5 答辩及整理文稿 nts 2-3 已查阅的主要参考文献 1、 全国数控培训网络天津分中心编 .数控机床 M.北京:机械工业出版社 ,1997 2、 .全国数控培训网络天津分中心编 .数控编程 M.北京:机械工业出 版社 ,1997 3、 .戴曙等 .金属切削机床 M.北京:机械工业出版社 ,1995 4、 金属切削机床设计 M 机械工业出版社 5、 金属切削机床设计手册 M 机械工业出版社 6、 大连 组合机床所编 组合机床设计手册 M 机械工业出版社 7、 上海纺织工学院等主编 金属切削机床图册 M 上海科技出版 社 指导教师意见 指导教师签名: 年 月 日 nts 3 毕业设计(论文)学生申请答辩表 课 题 名 称 数控回转工作台 指导教师(职称) 李兆铨 申 请 理 由 检验自己的成果 学生所在 系部 机电工程系 专业班级 05gb 机制 1 学号 0515011114 学生签名: 日期: 毕业设计(论文)指 导教师评审表 序号 评分项目(理工科、管理类) 评分项目 (文科 ) 满分 评分 1 工作量 外文翻译 15 2 文献阅读与外文翻译 文献阅读与文献综述 10 3 技术水平与实际能力 创新能力与学术水平 25 4 研究成果基础理论与专业知识 论证能力 25 5 文字表达 文字表达 10 6 学习态度与规范要求 学习态度与规范要求 15 总 分 100 评 语 ( 是否同意参加答辩) 指导教师签名: 另附毕业设计(论文)指导记录册 年 月 日 nts 4 毕业设计(论文)评阅人评审表 学生姓名 付勇 专业班级 05gb 机制 1 学号 0515011114 设计(论文)题目 数控回转工作台 评阅人 李兆铨 评阅人职称 高工 序号 评分项目(理工科、管理类) 评分项目 (文科 ) 满分 评分 1 工作量 外文翻译 15 2 文献阅读与外文翻译 文献阅读与文献综述 10 3 技术水平与实际能力 创 新能力与学术水平 25 4 研究成果基础理论与专业知识 论证能力 25 5 文字表达 文字表达 10 6 学习态度与规范要求 学习态度与规范要求 15 总 分 100 评 语 评阅人签名: 年 月 日 nts 5 毕业设计(论文)答辩表 学生姓名 付勇 专业班级 05gb 机制 1 学号 0515011114 设计(论文)题目 数控回转工作台 序号 评审项目 指 标 满分 评分 1 报告内容 思路清新;语言表达准确,概念清楚,论点正确;实验方法科学,分析归纳合理;结论有应用价值。 40 2 报告过程 准备工作充分 ,时间符合要求。 10 3 创 新 对前人工作有改进或突破,或有独特见解。 10 4 答 辩 回答问题有理论依据,基本概念清楚。主要问题回答准确,深入。 40 总 分 100 答 辩 组 评 语 答辩组组长(签字): 年 月 日 答 辩 委 员 会 意 见 答辩委员会负责人(签字): 年 月 日 nts 6-1 毕业设计(论文)答辩记录表 学生姓名 付勇 专业班级 05gb 机制 1 学号 0515011114 设计(论文)题目 数控回转工作台 答辩 时间 2009-6-8 答辩 地点 答辩委员会名单 朱森酉 李兆铨 王海涛 蒋小盼 问题 1 提问人: 问题: 回答(要点): 问题 2 提问 人: 问题: 回答(要点): 问题 3 提问人: 问题: 回答(要点): 记录人签名 (不足加附页) nts 6-2 问题 4 提问人: 问题: 回答(要点): 问题 5 提问人: 问题: 回答(要点): 问题 6 提问人: 问题: 回答(要点): 问题 7 提问人: 问题: 回答(要点): 问题 8 提问人: 问题: 回答(要点): 记录人签名 nts 7 毕业设计(论文)成绩评定总表 学生姓名: 付勇 专业班级: 05 机制 (1) 毕业设计(论文)题目: 数控回转工作台 注:成绩评定由指导教师、评阅教师和答辩组分别给分 (以百分记 ),最后按“优 (90-100)”、“良 (80-89)”、“中 (70-79)”、 “及格 (60-69)”、“不及格 (60 以下 )”评定等级。其中, 指导教师评定成绩占 40%,评阅人评定成绩占 20%,答辩组评定成绩占 40%。 成绩类别 成绩评定 指导教师评定成绩 评阅人评定成绩 答辩组评定成绩 总评成绩 40%+ 20%+ 40% 评定等级 nts 摘 要 数控车床今后将向中高挡发展,中档采用普及型数控刀架配套,高档采用动力型刀架,兼有液压刀架、伺服刀架、立式刀架等品种,预计近年来对数控刀架需求量将大大增加。但是 数控回转工作台更有发展前途 ,它是一种可以实现圆周进给和分度运动的工作台,它常被使用于卧式的镗床和加工中心上,可提高加工效率,完成更多的工艺,它主要由原动力、齿轮传动、蜗杆传动、工作台等部分组成,并可进行间隙消除和蜗轮加紧,是一种很实用的加工工具。本课题主要介绍了它的原理和机械结构的设计, 并对以上部分运用 AUTOCAD做图 ,最后是对 数控回转工作 台 提出的一点建议。 关键词: 数控回转工作台 齿轮传动 蜗杆传动 间隙消除 蜗轮加紧 nts Abstract Numerical control there is in the future lathe to in will develop, the middle-grade to adopt popular numerical control knife rest form a complete set, adopt the motive force type knife rest top-grandly, have such varieties as knife rest of hydraulic pressure, servo knife rest, vertical knife rest, etc. concurrently, it is estimated that it will increase to numerical control knife rest demand greatly in recent years. The development trend of the Numerical control rotary table is: With the development of numerical control lathe, numerical control knife rest begin to change one hundred sheets , electric liquid is it urge and urge direction develop while being servo to make up fast. Some originally design and is it continue electricity to use to four worker location vertical electronic machinery of knife rest mainly- exposed to control system control some designs. And use AUTOCAD to pursue to the above part, have a more ocular knowledge of electronic knife rest. The last proposition has put forward the suggestion and measure to Numerical control rotary table. Keywords: Numerical control rotary table; Gear drive; Worm drive;Gap elimination; The worm gear steps up. nts 目 录 摘要 . I Abstract . II 绪论 . 1 第一章:数控回转工作台的原理与应用 . 2 1.1 数控回转工作的原理 . 2 1.2 设计准则 . 4 1.3 主要技术参数 . 4 1.4 本章小结 . 4 第二章:数控回转工作台的结构设计 . 5 2.1 传动方案的确定 . 5 2.2 齿轮传动的设计 . 7 2.3 电液脉冲马达的选择及运动参数的计算 . 9 2.4 蜗轮及蜗杆的选用与校核 . 11 2.5 蜗杆与蜗轮的主要参数与几何尺寸 . 13 2.6 轴的校核与计算 . 15 2.7 弯矩组合图 . 16 2.8 齿轮上键的选择及校核 . 17 2.9 轴承的选用 . 17 2.10 本章小结 . 19 第三章 数控技术发展趋势 . 20 3.1 性能发展方向 . 20 3.2 功能发展方向 . 20 3.3 体系结构的发展 . 21 3.4 智能化新一代 PCNC数控系统 . 22 第四章 总结 . 23 致谢 . 24 参考文献 . 25 nts nts 1 The development trend of the numerical control technology Summary : Have introduced numerical control technology and the development trend of the equipment and the current situations of the technical development of numerical control equipment and industrialization of our country of our times briefly , have discussed under the new environment further deepened in our countrys accession to the WTO and opening to the outside world on this basis, develop technology of numerical control of our country and the importance of the information-based level of manufacturing industry of our country and international competitiveness equips , improves, and has put forward technology of numerical control of our country and some views equipped of developing from two aspects of strategy and tactics. The engineering level of equipment industry and modernized intensity are determining the level of the whole national economy and modernized intensity , numerical control technology and equip , develop new developing new high-tech industry and most advanced industry To can make technology and basic equipment most (national defense industry industries , such as information technology and their industry , biotechnology , industry , aviation , spaceflight ,etc. ). Marx has ever said the differences of different economic times, do not lie in what is produced , lie in how produce , with what means of labor produce . Manufacturing technology and equipping the most basic means of production that are that the mankind produced the activity, and numerical control technology to equip most central technology. Nowadays the manufacturing industry all around the world adopts the technology of numerical control extensively, in order to improve manufacturing capacity and level, improve the adaptive capacity and competitive power to the changeable market of the trends . In addition every industrially developed country in the world also classifies the technology and numerical control equipment of numerical control as the strategic nts 2 materials of the country, not merely take the great measure to develop ones own numerical control technology and industry, and implement blockading and restrictive policy to our country in high-grade , precision and advanced key technology and equipment of numerical control. In a word, develop taking technology of numerical control as the core advanced manufacturing technology become world all developed country , accelerate economic development already in a more cost-effective manner, important route to improve the comprehensive national strength and national position. Numerical control technology to go on technology that control with digital information to mechanical movement and working course, numerical control equipment whether represented by technology of numerical control new technology make industry and new developing infiltration electromechanics integrated product that form of manufacturing industry to tradition, i.e. what is called digitization equip, its technological range covers a lot of fields: (1)Mechanical manufacturing technology; (2)Information processing , processing , transmission technology; (3)Automatic control technology; (4)Servo drive technology; (5)Transducer technology; (6)Software engineering ,etc. 1 Development trend of a numerical control technology The application of the technology of numerical control has not only brought the revolutionary change to traditional manufacturing industry, make the manufacturing industry become the industrialized symbol , and with the constant development of the technology of numerical control and enlargement of application, the development of he some important trades (IT , car , light industry , medical treatment ,etc. ) to the national economy and the peoples livelihood plays a more and more important role, because these trade necessary digitization that equipped has already been the main trend of modern development. According to the technology of numerical control and equipment development trend in the world at nts 3 present, its main research focus has the following several respect 14. 1.1 A high-speed , high finish machining technology and new trend equipped Efficiency , quality are subjects of the advanced manufacturing technology. At a high speed, high finish machining technology can raise the efficiency greatly, quality and grade to raise product, shorten production cycle and improve the competitive power of market. Japan carry technological research association classify their as one of the 5 loud modern manufacturing technologies first for this reason, learn (CIRP ) to confirm it as the centre in the 21st century to study one of the directions in international production engineering. In the field of car industry, produce 40 second when beat such as production of 300,000 / vehicle per year, and many variety process it is car that equip one of the key problems that must be solved; In the fields of aviation and aerospace industry, its processings spare parts are mostly the thin wall and thin muscle, rigidity very bad, material aluminium or aluminium alloy, in high to cut pace and cut strength very under the little situation only, could process these muscles , walls . Adopt large-scale whole aluminium alloy blank method of pay empty make the wing recently, large-scale parts such as the fuselage ,etc. come to substitute a lot of parts to assemble through numerous rivet , screw and other connection ways, make the intensity , rigidity and dependability of the component improved. All these requirement for processing and equipping and proposing high-speed , high and precise and high flexibility. According to EMO2001 exhibition situation, the high-speed machining center enters for the pace to can reach 80m/min , even high, air transport competent pace can reach 100m/min about. A lot of car factories in the world at present, including Shanghai General Motors Corporation of our country, adopt , substitute and make the lathe up with high-speed machining center production line part that make up already. HyperMach lathe of Company , CINCINNATI of U.S.A. , enter , give pace to be most nts 4 loud to reach 60m/min, it is 100m/min to be fast, acceleration reach 2g, the rotational speed of the main shaft has already reached 60 000r/min. Processing a thin wall of plane parts, spend 30min only, and same part general at a high speed milling machine process and take 3h, process and need 8h with ordinary milling machine; The paces and acceleration of main shaft of dual main shaft lathes of Germany DMG Company reach 12* separately! 000r/mm and 1g. In machining accuracy, in the past 10 years, ordinary progression has accused of the machining accuracy of the lathe to already improve from 10m to 5m, accurate grades of machining center from 3- 5m, raise to 1- 1.5m, and ultraprecision machining accuracy begin , enter getting nanometer already. In machining accuracy, the past 10 years, ordinary progression accuse of machining accuracy of lathe raise to 5m , from 3- 5m accurate grades of machining center from 10m already, improve to 1- 1.5m, and the ultraprecision machining accuracy has already begun to enter nanometer (0.01m )ly. In dependability, MTBF value of the foreign numerical control device has already reached above 6 000h, MTBF value of the servo system reaches above 30000h, demonstrate very high dependability . For realize at a high speed , high finish machining, related to it function part if electric main shaft , straight line electrical machinery get fast development, the application is further expanded . 1.2 5 axles link and process and compound and process the lathe to develop fast Adopt 5 axle link , to three-dimensional curved surface processing of part , can cut with the best geometirc form of the cutter, not only highly polished, but also efficiency is improved by a large margin . It is generally acknowledged , a 5 axle gear beds of efficiency can equal 2 3 axle gear beds , use cubic nitrogen boron wait ultra hard material milling cutter go on at a high speed milling , sharpening , quenching hard steel at the part, 5 axle link , process constant 3 axle link , process , give play to high benefit. But go over because 5 axles link the numerical control nts 5 system , complicated reason of host computer structure, price its link numerical control to be lathe several times higher than 3 axle, in addition programming technological difficulty relatively heavy , have restricted 5 axle gear beds of development. At present because of electric appearance of main shaft, make , realize 5 axle compound main shaft hair structure processed to link greatly simplify, it make difficulty and cost reduce by a large margin , numerical control price disparity of systems shrink. So promote compound main shaft head type 5 axle gear bed and compound development to process lathe (process the lathe including 5 ). At EMO2001 exhibition, new Japanese 5 of worker machine process lathe adopt compound main shaft hair, can realize 4 processing and arbitrary processing of angle of vertical plane, make 5 process and 5 axles are processed and can be realized at the same lathe, can also realize the inclined plane and pour the processing of the hole of awls . Company , DMG of Germany , exhibit DMUVoution series machining center , can put , insert , down 5 process and 5 axes link and process in one, can be controlled by CNC system or CAD/CAM controls directly or indirectly. 1.3 intellectualizations, open style, the network turns into for the contemporary numerical control system development mainly hastens The 21st century numerical control equipments will be has certain intellectualized the system, the intellectualized content including in numerical control system each aspect: In order to pursue the processing efficiency and the processing quality aspect intellectualization, like processing process adaptive control, craft parameter automatic production; In order to enhance the actuation performance and the use connection convenient intellectualization, like the feed-forward control, the electrical machinery parameter auto-adapted operation, the automatic diagnosis load automatic designation model, is automatic entire grades; Simplification programming, simplification operation aspect intellectualization, like intellectualized automatic programming, nts 6 intellectualized man-machine contact surface and so on; Also has the intelligence to diagnose, the intelligent monitoring aspect content, the convenience system diagnosis and the service and so on In order to solve the traditional numerical control system seal and the numerical control application software industry production existence question. At present many countries conduct the research to the open style numerical control system, like USS NGC (The Next Generation Work-Station/Machine Control), European Economic Communitys OSACA (Open System Architecture for Control within Automation Systems), Japans OSEC (Open System Environment for Controller), Chinas ONC (Open Numerical Control System) and so on. The numerical control system will open already becomes the numerical control system road of the future. The so-called open style numerical control system is the numerical control system development may in the unified movement platform, face the engine bed factory and the end-user, through the change, the increase or the tailor structure object (numerical control function), forms the seriation, and may conveniently integrates users special application and the technical knack in the control system, the fast realization different variety, the different scale open style numerical control system, forms has the bright individuality famous brand goods. At present the open style numerical control system system structure standard, the correspondence standard, the disposition standard, the movement platform, the numerical control system function storehouse as well as the numerical control system function software development kit and so on is the current research core The network numerical control equipment is a nearly two year international famous engine beds expositions new luminescent spot. The numerical control equipment network enormously will satisfy the production line, the manufacture system, the manufacture enterprise to the information integration demand, also will be realizes new manufacture pattern like agile manufacture, hypothesized enterprise, the nts 7 global manufacture foundation unit. The domestic and foreign some famous numerical controls engine bed and the numerical control system manufacture company has all promoted the related new concept and the prototype in the nearly two years, if unfolds in EMO2001, Japanese Shan Qima Mazak the company displays CyberProduction Center (intelligence production control center, is called CPC); Japan is Okuma the engine bed company to display IT plaza (information technology square, is called the IT square); German Simens (Siemens) the company displays Open Manufacturing Environment (opening manufacture environment, is called OME) and so on, had reflected the numerical control engine bed processing the tendency which develops to the network direction 1.4 takes the new technical standard, the standard establishment 1.4.1 about numerical control system design development gauge As noted previously, there are better commonability , flexibility , adaptability , expanding in the open numerical control system, countries such as U.S.A. , European Community and Japan ,etc. implement the strategic development plan one after another , carry on research and formulation of the systematic norm of structural numerical control of the open system (OMAC , OSACA , OSEC ), 3 of world heavy economy carry on the same science plan and standardize formulation nearly in a short time most, have indicated a new arrival of period of change of the technology of numerical control. Our country started research and formulation which standardized the frame of ONC numerical control system of China too in 2000. 1.4.2 About the numerical control standard The numerical control standard is a kind of trend of information-based development of manufacturing industry. Numerical control technology information exchange of 50 year born , to based on ISO6983 standard, adopt G , M code describes how processes, its essential characteristic faces the processing course, obviously, he cant meet demands of nts 8 high-speed development of the technology of modern numerical control more and more already. For this reason, studying and making a kind of new CNC system standard ISO14649 (STEP-NC ) in the world, its purpose is offering a kind of neutral mechanism not depending on the concrete system , can describe the unified data model in whole lifespan of the products , thus realize the whole manufacture process, and even the standardization of each industrial field product information. The appearance of STEP-NC may be a revolution of the technical field of the numerical control, on development and even the whole manufacturing industry of the technology of numerical control , will exert a far-reaching influence. First of all, STEP-NC puts forward a kind of brand-new manufacture idea , in the traditional manufacture idea, NC processes the procedures to all concentrate on single computer. Under the new standard, NC procedure can be dispersed on Internet, this is exactly a direction of open , networked development of technology of numerical control. Secondly, STEP-NC numerical control system also can reduce , process (about 75% ) drawing , process procedure work out (about 35% ) time and process (about 50% ) time greatly. At present, American-European countries pay much attention to the research of STEP-NC, Europe initiates IMS plan (1999.1.1- 2001.12.3 ) of STEP-NC. 20 CAD/CAM/CAPP/CNC users , manufacturers and academic organizations from Europe and Japan participated in this plan. STEP Tools Company of U.S.A. is a developer of the data interchange software of manufacturing industry in the global range, he has already developed and accused of the super model (Super Model ) of information exchange of machine tooling by counting, its goal is to describe all processing courses with the unified norm. Such new data interchange form has already been verified in allocating the SIEMENS , FIDIA and European OSACA-NC numerical control at present. 2 pairs of basic estimations of technology and industry development of numerical control of our country nts 9 The technology of numerical control of our country started in 1958, the development course in the past 50 years can roughly be divided into 3 stages: The first stage is from 1958 to 1979, i.e. closed developing stage. In this stages, technology of foreign countries blockade and basic restriction of terms of our country, the development of the technology of numerical control is comparatively slow. During Sixth Five-Year Plan Period , the Seventh Five-Year Plan Period of the country in second stage and earlier stage in the Eighth Five-Year Plan Period , introduce technology , digest and assimilate, the stage of establishing the system of production domesticization arisesing tentatively. At this stage , because of reform and opening-up and national attention , and study the improvement of the development environment and international envir

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号